Gas reservoir stress sensitivity evaluating experiment method considering bound water under formation condition

A stress-sensitive, formation-conditional technology for earthmoving, wellbore/well components, production fluids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

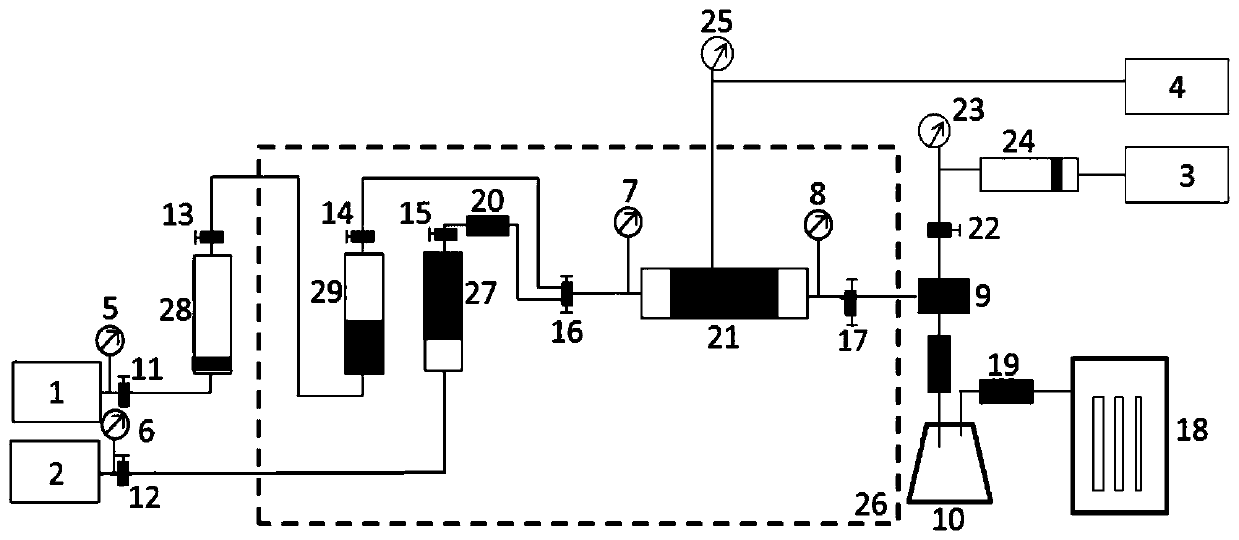

Method used

Image

Examples

Embodiment 1

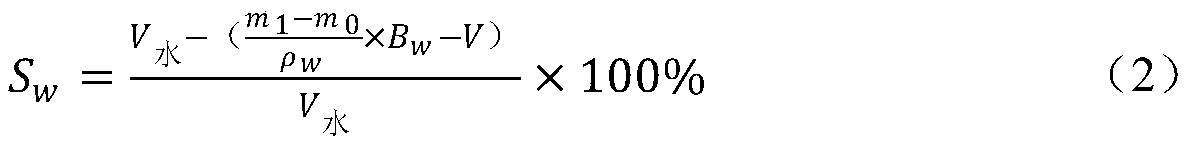

[0182] 1. Core preparation, after extracting, cleaning and drying the core retrieved from the site, measure the length of the core L=7.41cm, diameter d=2.49cm, gas permeability K=10.8mD, porosity And calculate the cross-sectional area of the core A=4.87cm 2 ;

[0183] 2. Fluid preparation: prepare simulated formation water according to the formation water sample data of the actual gas reservoir; take natural gas from the actual gas reservoir as the experimental gas; put the water sample intermediate container 27 at room temperature, and put the high-pressure gas sample into the gas sample intermediate container 28 Fill the humidification intermediate container 29 with 50% volume of formation water, then inject 50% high-pressure gas sample, and stir for 2 hours to make excess gas dissolve in the water.

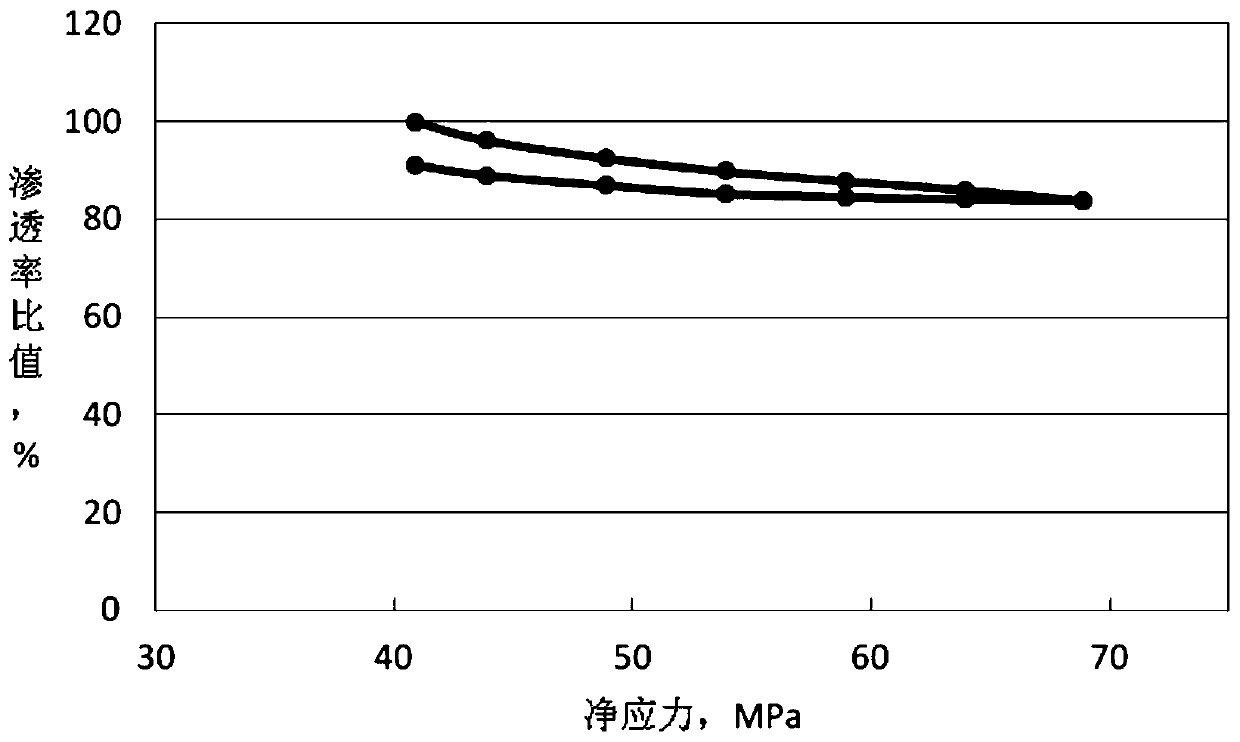

[0184] 3. Experimental temperature and pressure, the confining pressure is 78.9MPa, the temperature is 151℃, the core pore pressure is 38MPa, 35MPa, 30MPa, 25MPa, 20MPa, 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com