Measuring Temperature for Monitoring and Control of a Fiber Web or Finishing Machine

A health, paper technology, applied in paper machines, transport and packaging, temperature measurement of moving solids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

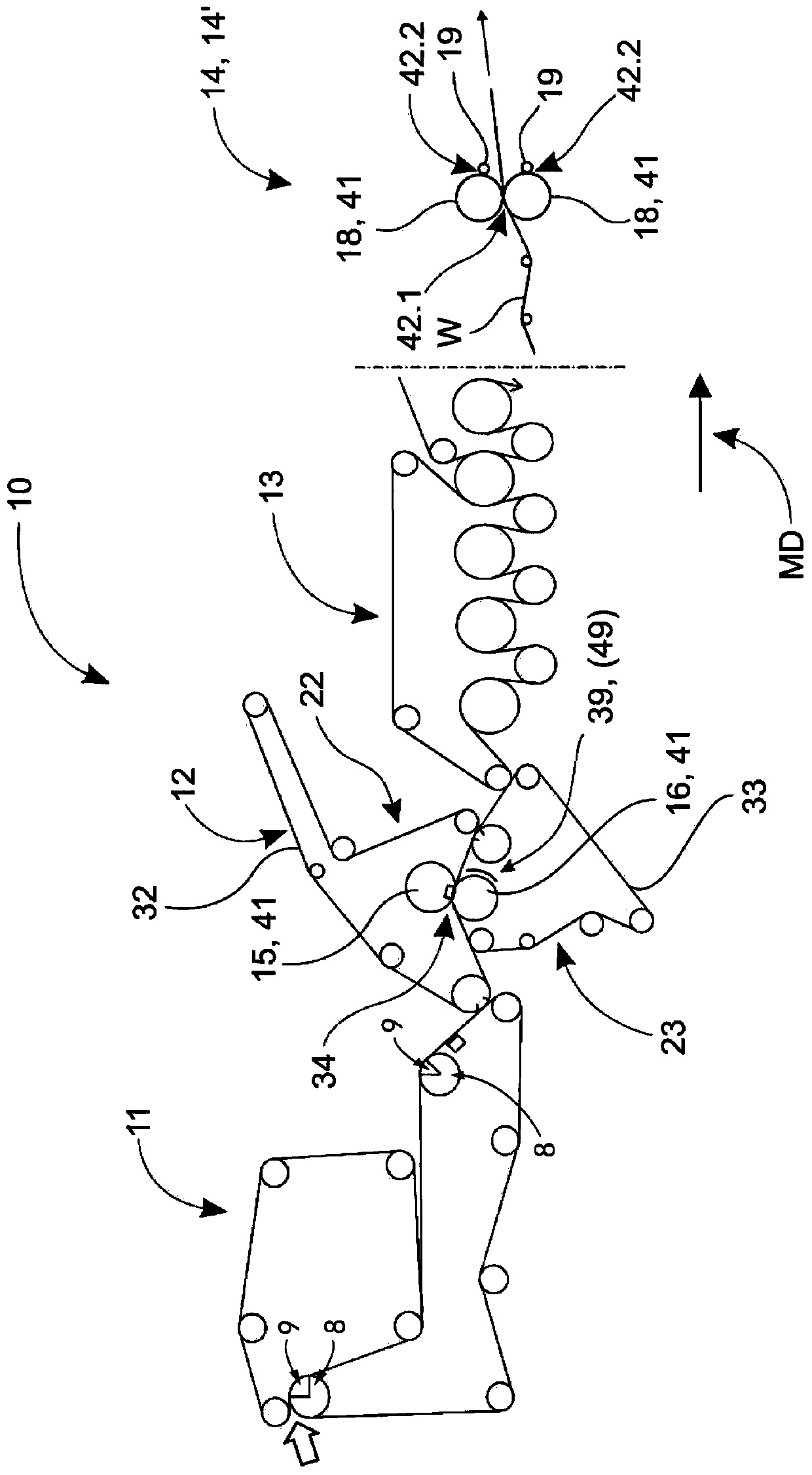

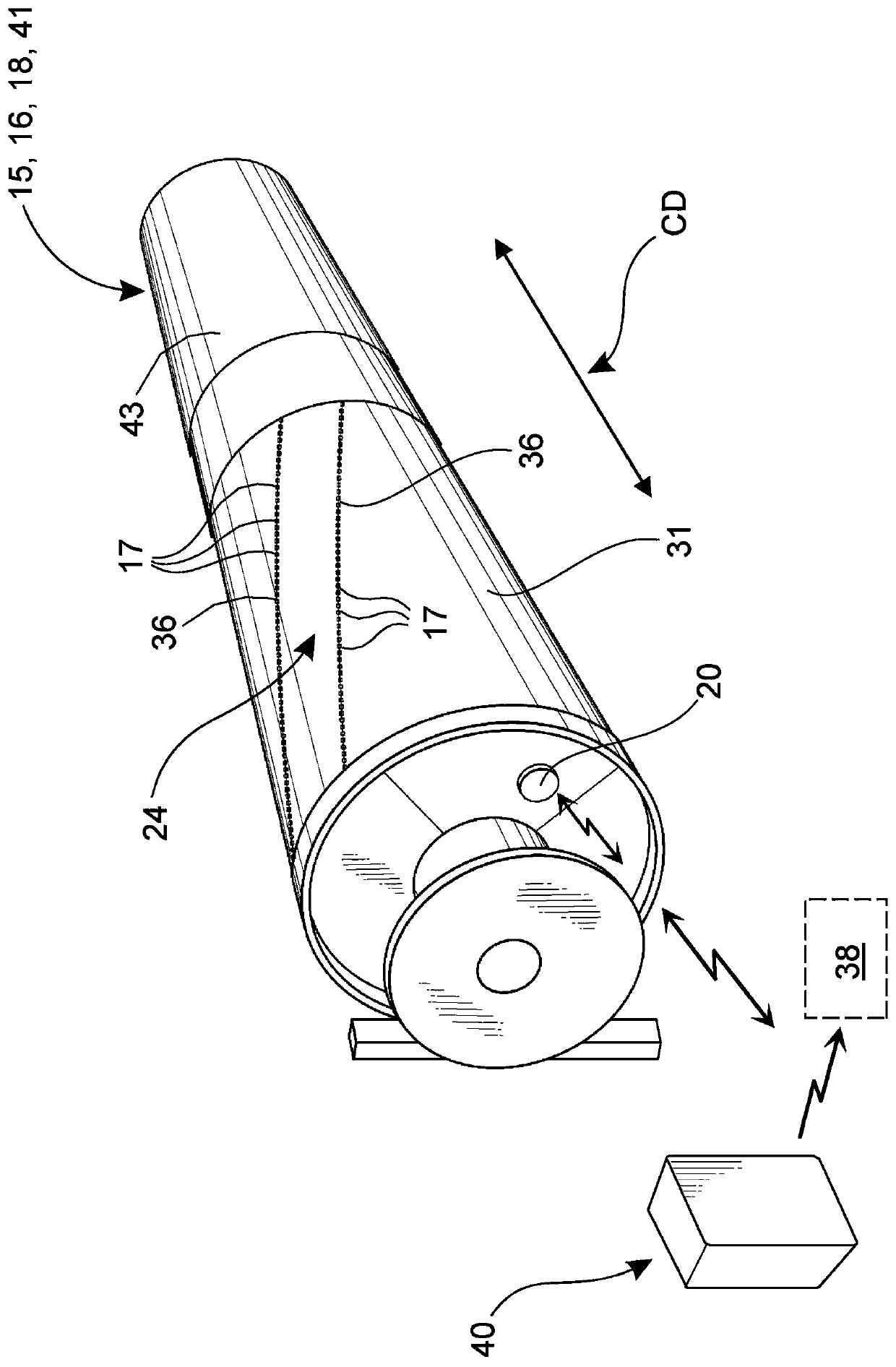

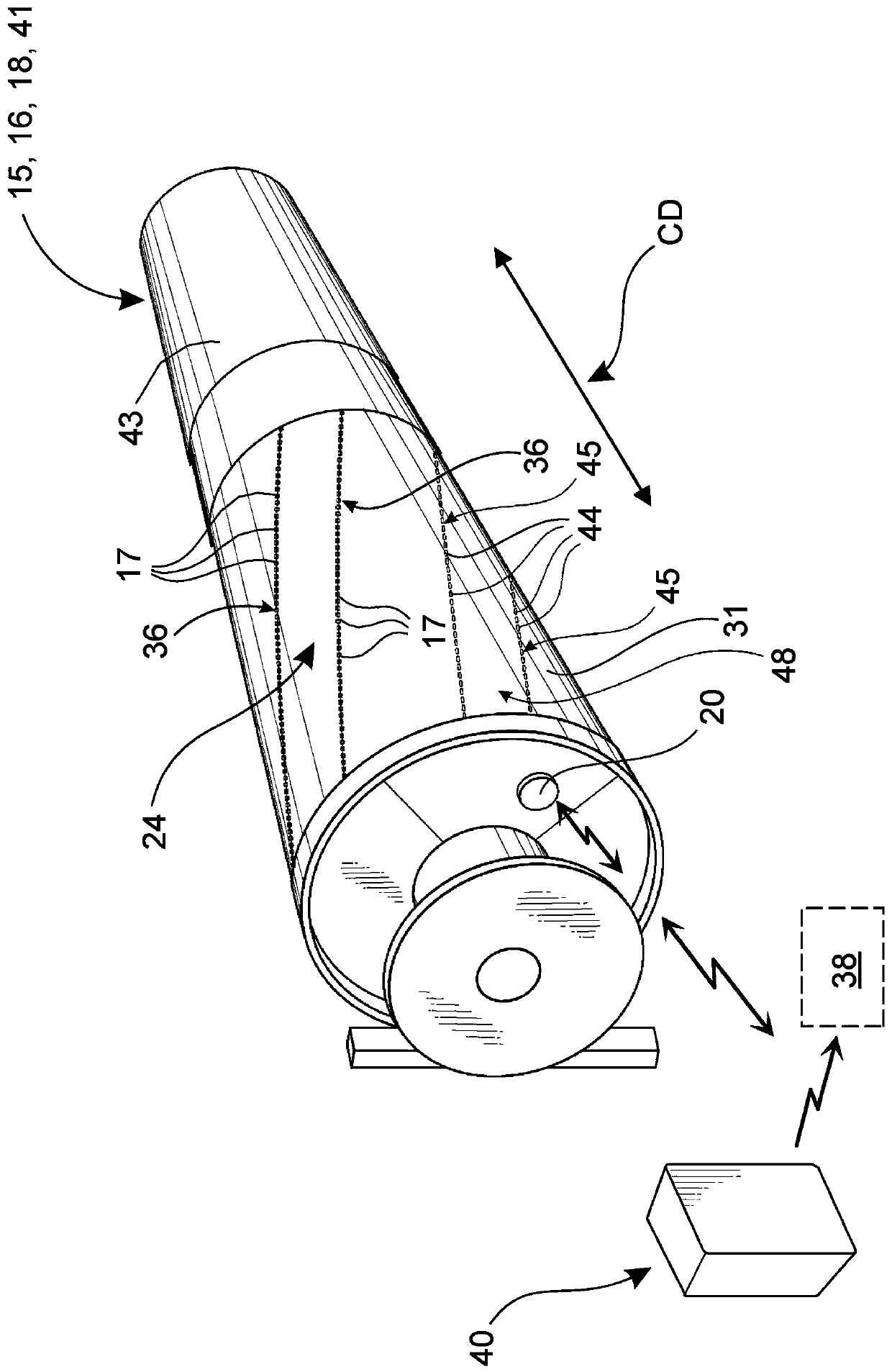

[0025] figure 1 A rough schematic diagram of an example of an application of the invention is shown, where the application here is a fiber web machine 10 . In addition to fiber web machines 10, the invention can also be used, for example, in paper finishing machines 14, such as figure 1 As shown, the paper finishing machine 14 is located at the end of the fiber web machine 10 when viewed in the machine direction MD (machine direction). Some examples of paper finishers 14 include winding, slitting, calendering, coating, surface sizing 14', and rewinding.

[0026] A fiber web machine or paper finishing machine comprises one or more fruit bodies 11-14. The fiber web machine 10 may comprise a continuous fruit body in the direction of travel of the web W, in other words in the machine direction MD (from figure 1 ) comprising: a headbox (not shown), a web forming section 11, a press section 12, a dryer section 13, one or more possible paper finishing equipment 14, wherein a surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com