Mobile phone glass cover plate window area defect detection method based on machine vision

A glass cover and defect detection technology, applied in the field of visual inspection, can solve the problems of unstable detection process, missed detection and over-inspection rate, etc., and achieve the effect of high detection efficiency, high versatility and flexible and adjustable detection accuracy of the algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be described in further detail below in conjunction with specific embodiments.

[0080] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

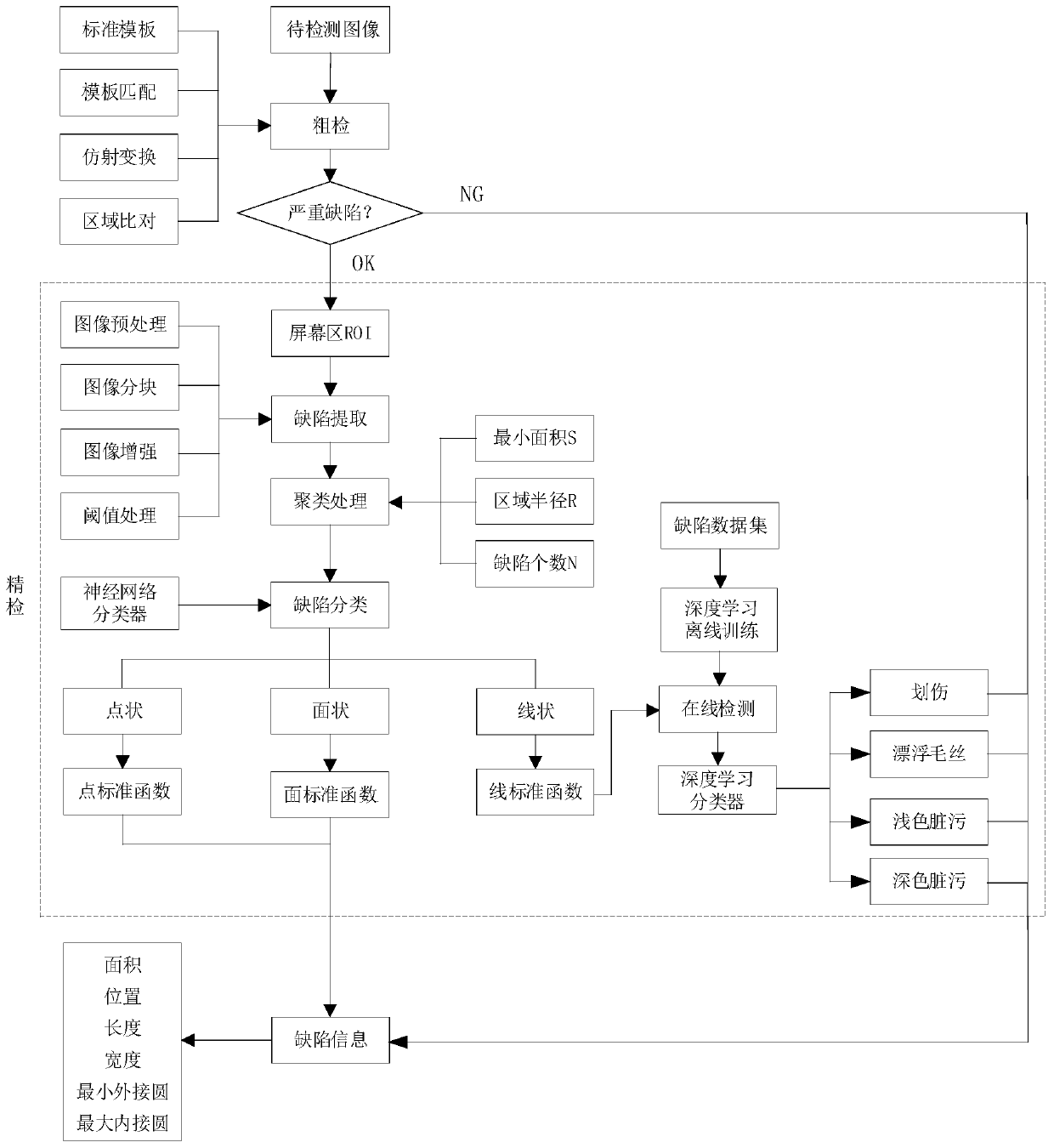

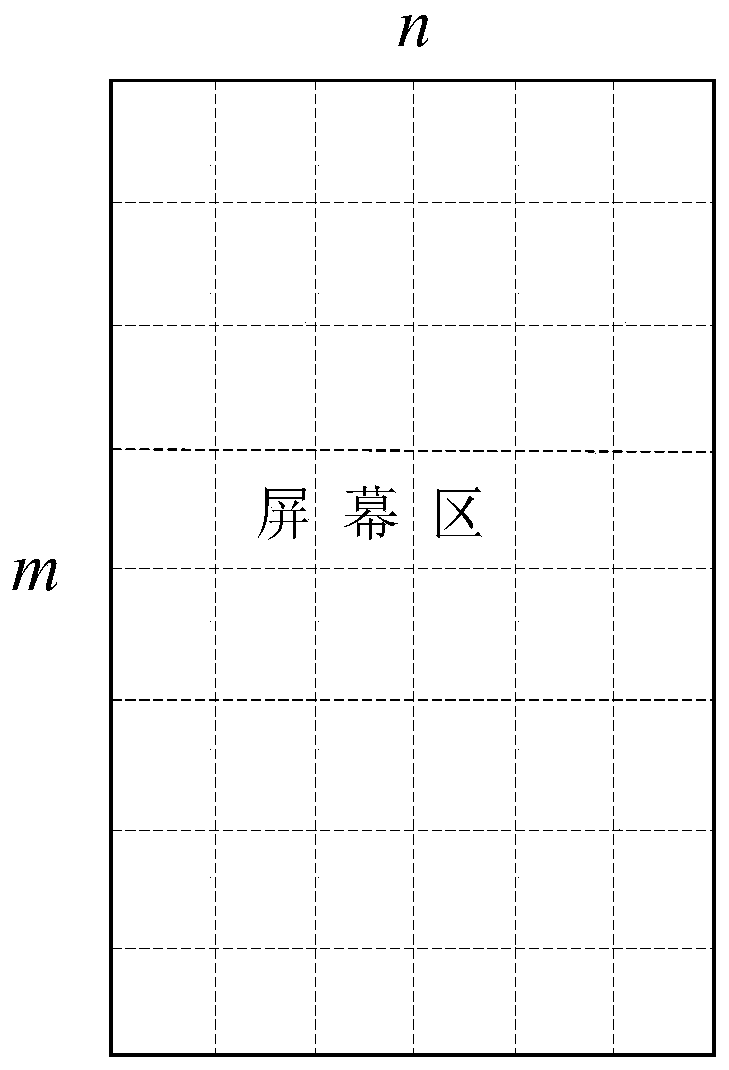

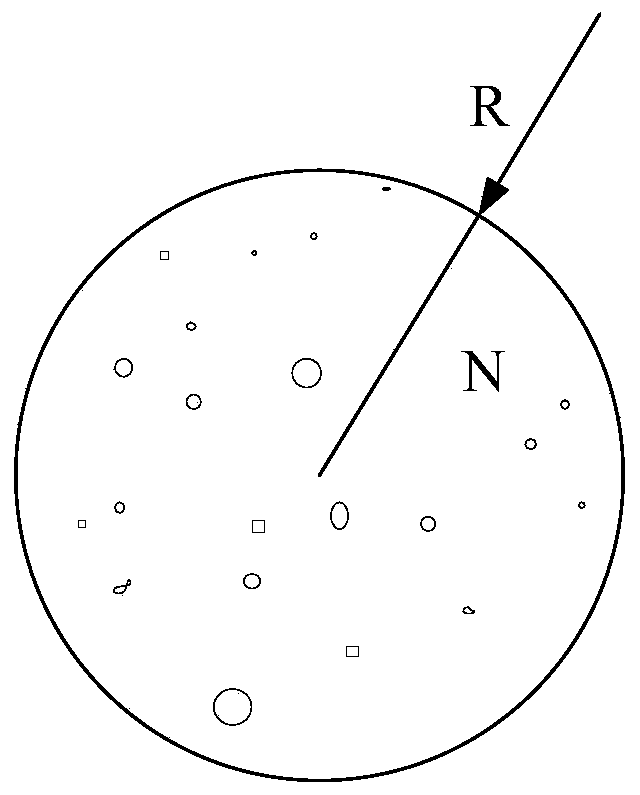

[0081] like figure 1 As shown, a machine vision-based method for detecting defects in the window area of the glass cover of a mobile phone mainly includes two parts: rough inspection and fine inspection. The rough inspection process includes four key steps: standard template making, template matching, affine transformation, and region comparison. If there are serious defects, the next step of fine inspection will be carried out. The fine inspection part mainly realizes the extraction and classification of defects. The region of interest (ROI) of the screen area of the image to be detected can be obtained according to the position and angle information ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com