Production process of automobile hub fastening component

A technology of fastening components and production process, which is applied in the field of production process of automobile wheel hub fastening components, which can solve the problems of simultaneous release of bolts, backward technology, and inability to obtain products, so as to avoid waste of resources, ensure normal operation, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

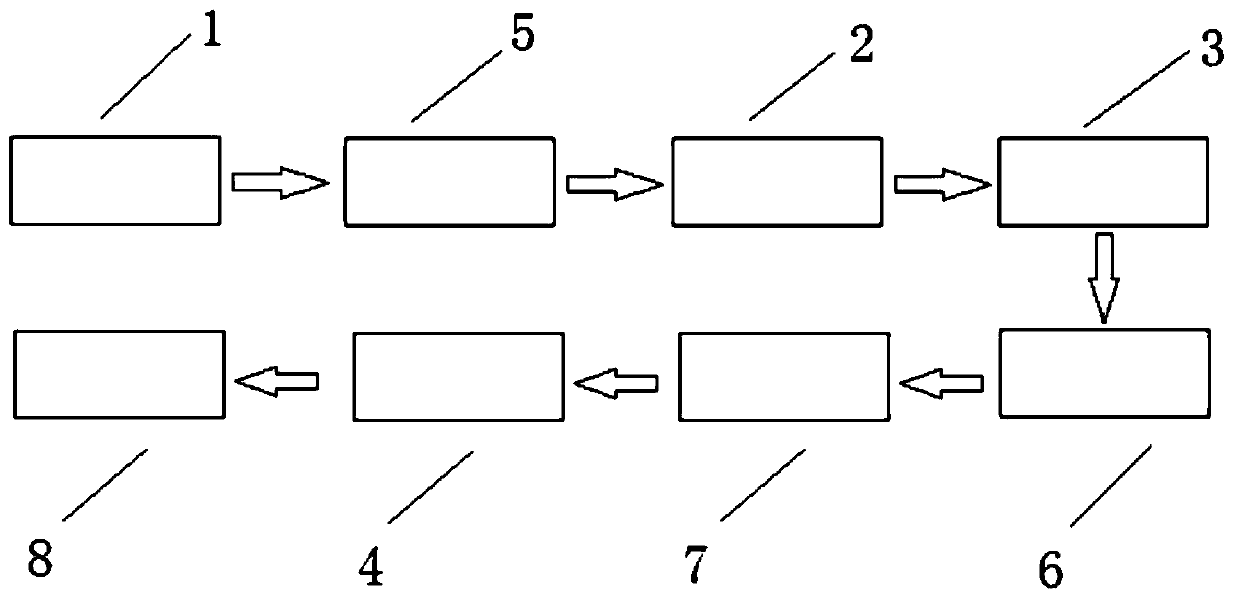

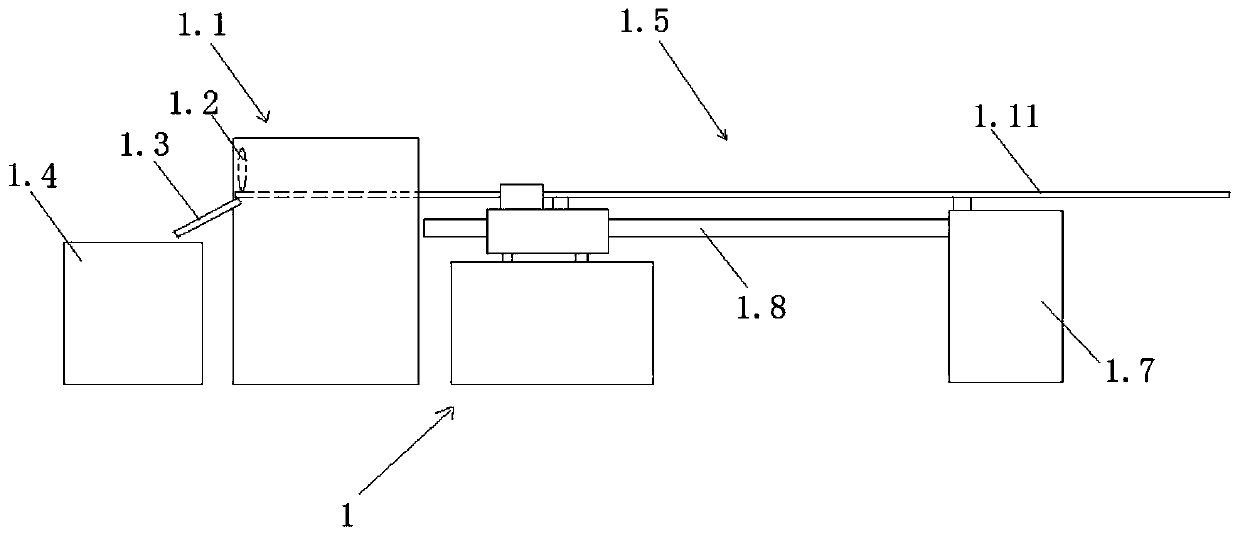

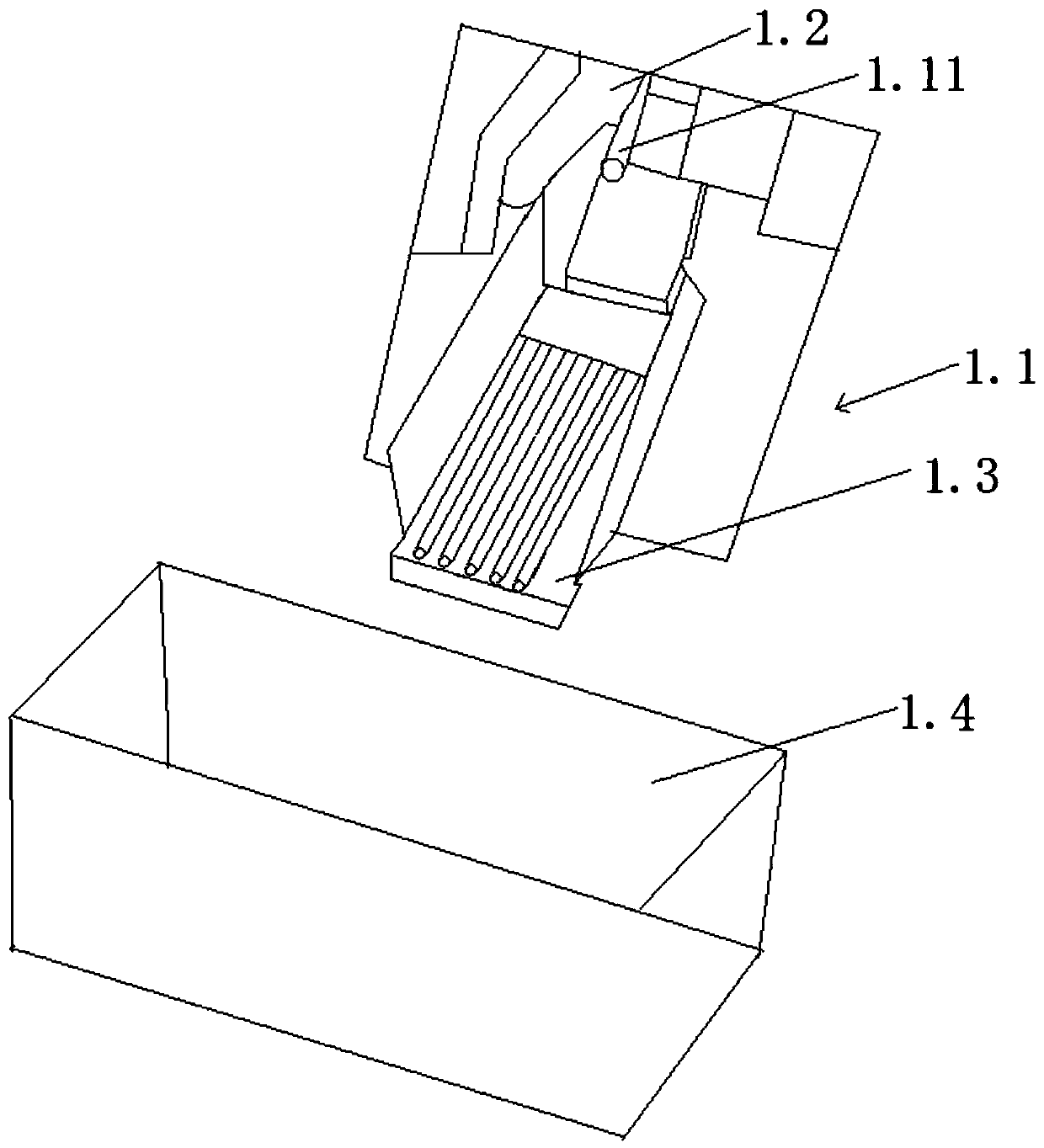

[0052] see Figure 1 to Figure 12 , the present invention relates to a kind of production technology of automobile hub fastening assembly, the concrete steps of this production technology are as follows:

[0053] 1) The material of the automobile wheel hub fastening component is a solid round blank of φ38mm, which is made of alloy steel, copper or other metal materials, and the solid round blank is ground and rounded;

[0054] 2) Send the polished round blank to the sawing device in the production equipment, and the sawing device will saw the round blank into the required length of the fastener;

[0055] 3) Put the sawn blank into the chamfering machine for chamfering;

[0056] 4) The chamfered blank is sent to the cold heading device in the production equipment for cold heading. After the cold heading is completed, the screw blank is formed and sent to the blank collection box;

[0057] 5) Manually send the screw blank in the blank collection box to the thread rolling devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com