Water purification device using membrane filtration process

A technology of water purification device and filtration method, which is applied in the direction of filtration treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., which can solve the problems of water purification filtration membrane unable to restore filtration function, shortening of filtration work cycle, pollution of water quality and ecological environment and other issues, to achieve the effect of reducing water and energy consumption, reducing energy consumption, and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

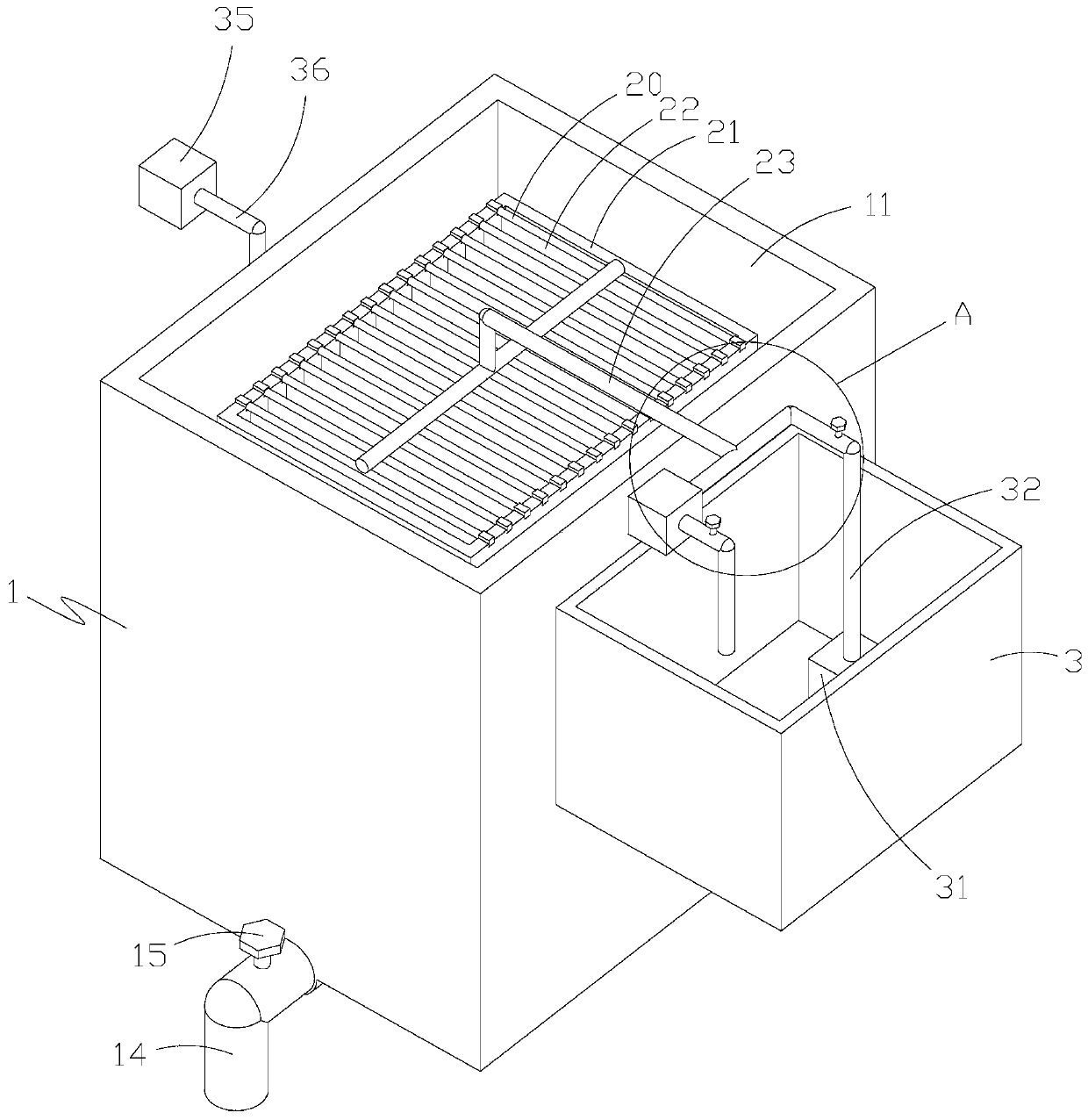

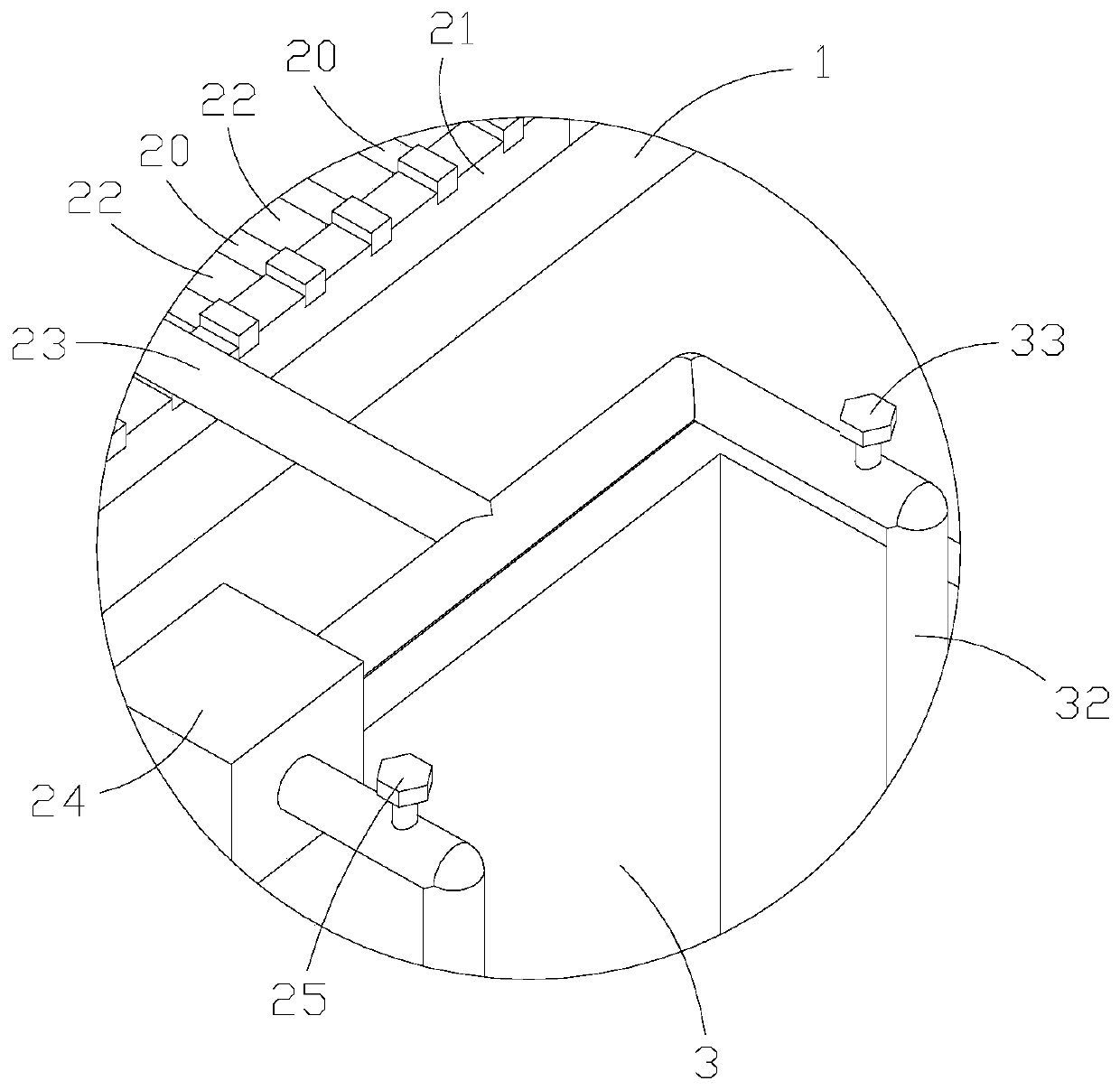

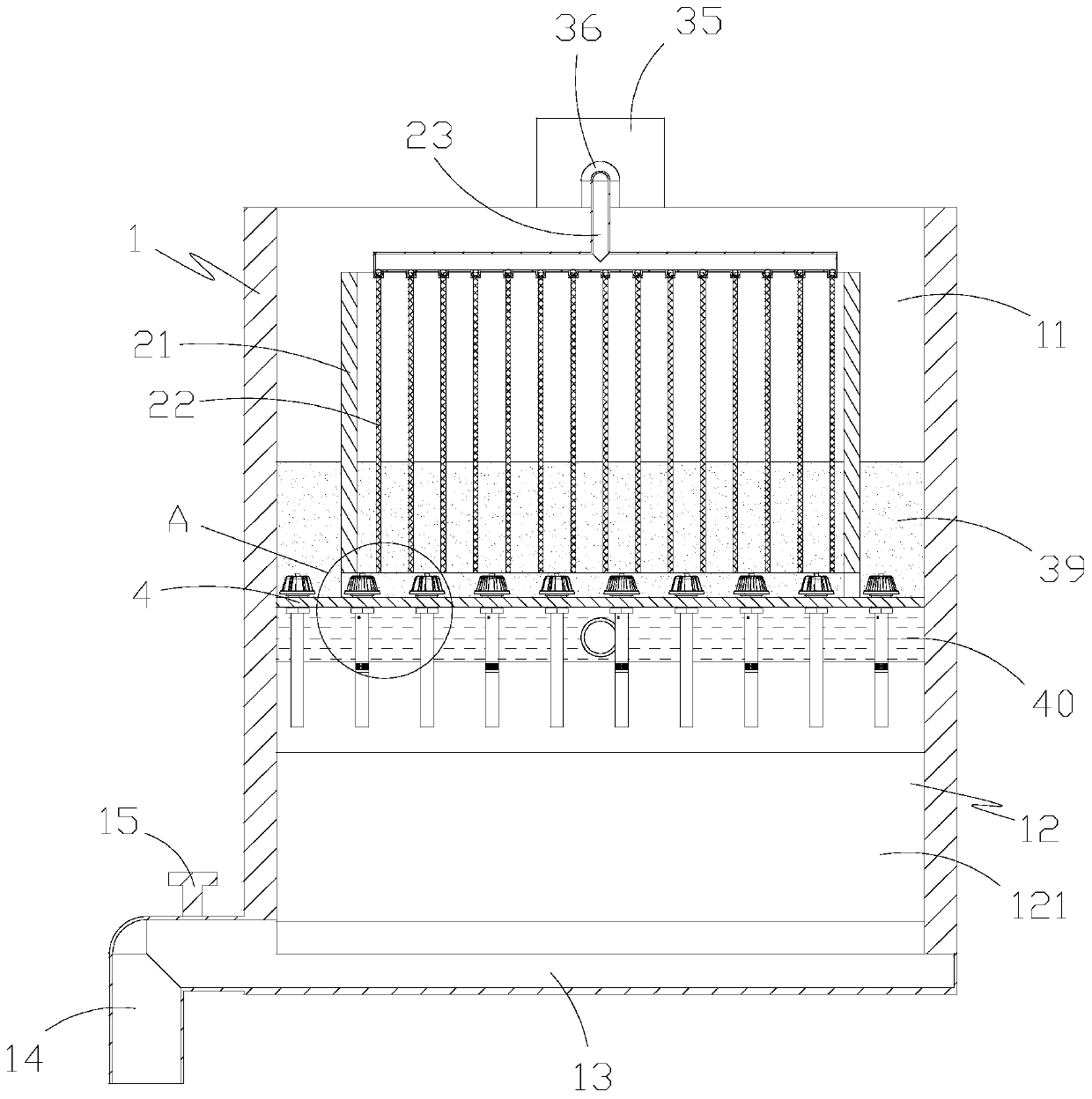

[0030] Such as Figure 1-9As shown, a membrane filtration method water purification device includes a filter tank 1, a filter device and a backwashing device; in this embodiment, the filter tank 1 is formed by pouring cement and is opened in a hollow cubic structure with an opening on the top. In an embodiment, the filter tank can also be made of metal material or other materials; wherein, the filter device includes a connecting pipe 20, a membrane frame 21, a filter membrane 22, a water collection pipe 23, a suction piece 24 and a water outlet valve 25; the filter membrane 22 is installed On the connecting pipe 20, the connecting pipe is installed on the membrane frame 21, and the two are detachably connected, which is convenient for disassembly, maintenance and replacement. What is used in this embodiment is plugging; the filter membrane 22 is a mesopore purchased on the market Membrane, this is the prior art, so it will not be described here; the holes at both ends of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com