Nanofluid-based drilling slag discharge and oscillating fracturing gas drainage system and method

A gas extraction and nanofluid technology, which is applied in the fields of fluid extraction, earthwork drilling, gas discharge, etc., can solve the problems of inability to ensure efficient gas extraction, insignificant reduction of crack initiation pressure, and poor hydraulic fracturing effect. Efficient and smooth drilling operation, promoting rapid desorption and good fracture depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

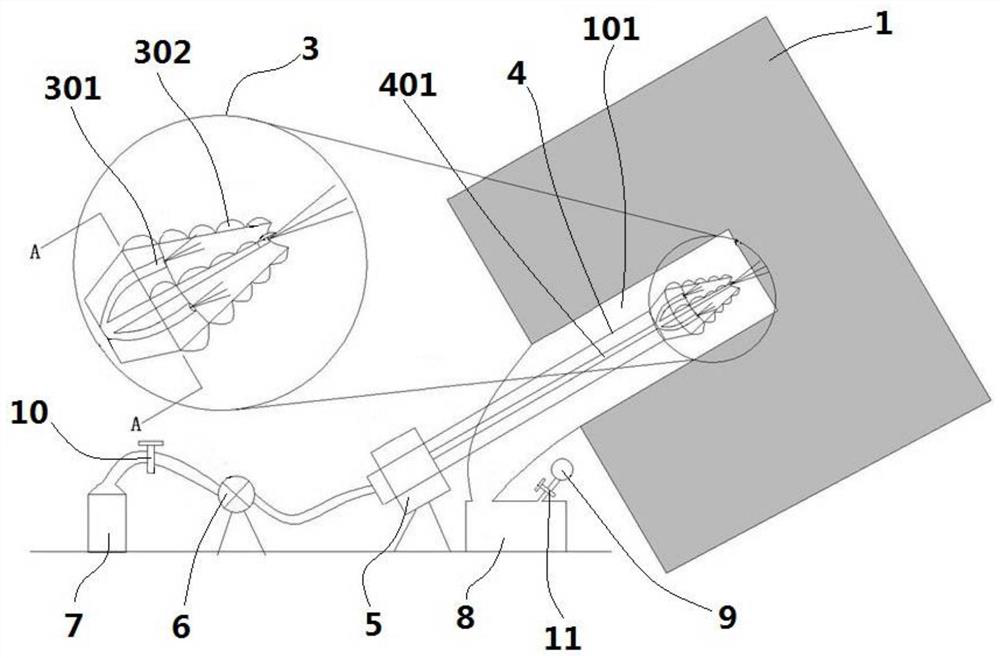

[0039]This embodiment discloses a drilling slag discharge and hydraulic oscillating fracturing enhanced gas drainage system based on nanofluid, including a drilling slag discharge device and a hydraulic oscillating fracturing enhanced gas drainage device.

[0040] The drilling slag discharge device includes a drill bit 3, a drill pipe 4, a drilling rig 5, a booster pump I6, a nanofluid storage tank I7, a gas slag separator I8 and a gas extraction pipeline I9.

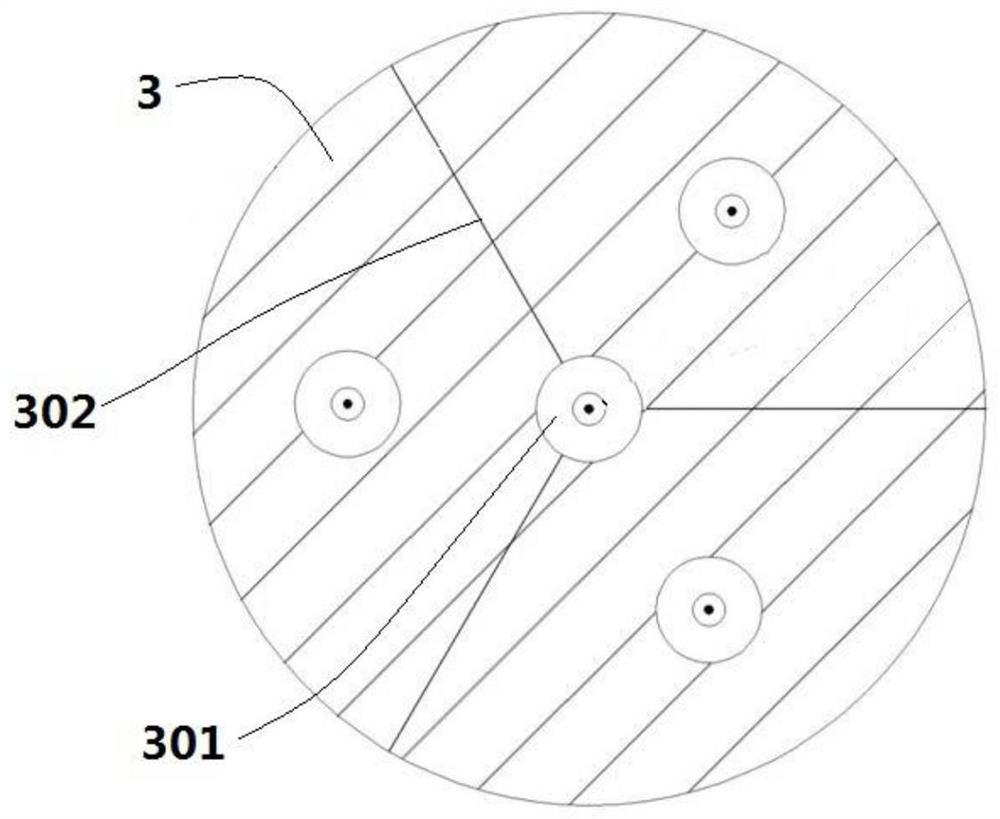

[0041] see figure 1 , One end of the drill rod 4 is provided with a drill bit 3 , and the other end is provided with a drill rig 5 . see figure 2 , the drill bit 3 is conical, the tip of the drill bit 3 is provided with a high-pressure nozzle 301, and the surface of the drill bit 3 is arranged with several high-pressure nozzles 301 and some serrations 302 at intervals, and several of the serrations 302 are all along the generatrix of the drill bit 3 Arrange evenly. The inside of the drill pipe 4 is provided with a n...

Embodiment 2

[0060] This embodiment discloses a method for using a nanofluid-based drilling slag discharge and hydraulic oscillating fracturing enhanced gas drainage system described in Embodiment 1, including the following steps:

[0061] 1. The gas extraction hole 101 is arranged on the surface of the coal seam 1, and the upper end of the gas slag separator I8 is opened and the airtight cover is arranged around the gas extraction hole 101. Put the hydrophilic nanofluid into the nanofluid storage tank I7, open the valve I10, start the drilling machine 5 to drive the drill pipe 4 and the drill bit 3 to rotate. Start the pressurizing pump I6 to make several high-pressure nozzles 301 in the drill bit 3 spray out high-pressure hydrophilic nanofluid to impact and break the coal rock mass. A circular platform with a hole in the middle is formed in front of the drill bit 3, and several of the saw teeth 302 are used to break the circular platform and drill forward. During the drilling process, t...

Embodiment 3

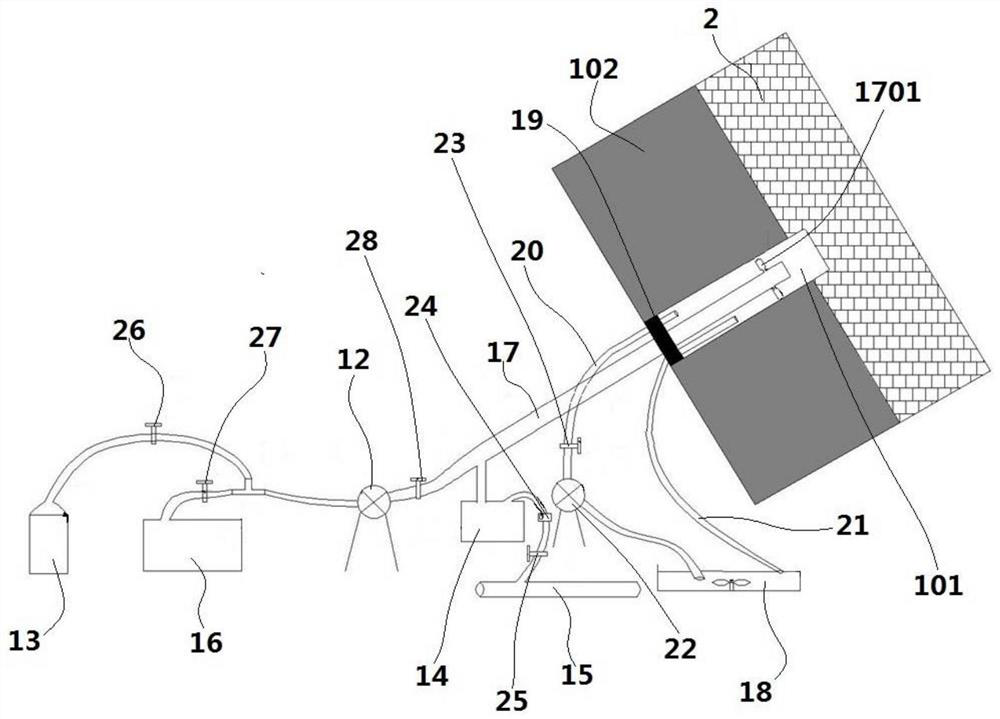

[0071] This embodiment discloses a drilling slag discharge and hydraulic oscillating fracturing enhanced gas drainage system based on nanofluid, including a drilling slag discharge device and a hydraulic oscillating fracturing enhanced gas drainage device.

[0072] The drilling slag discharge device includes a drill bit 3, a drill pipe 4, a drilling rig 5, a booster pump I6, a nanofluid storage tank I7, a gas slag separator I8 and a gas extraction pipeline I9.

[0073] see figure 1 , One end of the drill rod 4 is provided with a drill bit 3 , and the other end is provided with a drill rig 5 . see figure 2 , the drill bit 3 is conical, the tip of the drill bit 3 is provided with a high-pressure nozzle 301, and the surface of the drill bit 3 is arranged with several high-pressure nozzles 301 and some serrations 302 at intervals, and several of the serrations 302 are all along the generatrix of the drill bit 3 Arrange evenly. The inside of the drill pipe 4 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com