A step-by-step installation and construction method of electric heat tracing for chemical pipelines

A technology of chemical pipelines and construction methods, applied in pipeline heating/cooling, pipeline protection, pipeline protection through heat insulation, etc., can solve the inconvenience of laying steam heating pipelines, difficult control of steam heat dissipation, running, popping, dripping, and leaking and other problems, to achieve the effect of improving heat tracing efficiency, good heat preservation, and reducing the frequency of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0088] The following is an example of the step-by-step construction and installation project of the electric heat tracing of the molten bisphenol A pipeline to further illustrate the step-by-step installation and construction method of the electric heat tracing of the chemical pipeline:

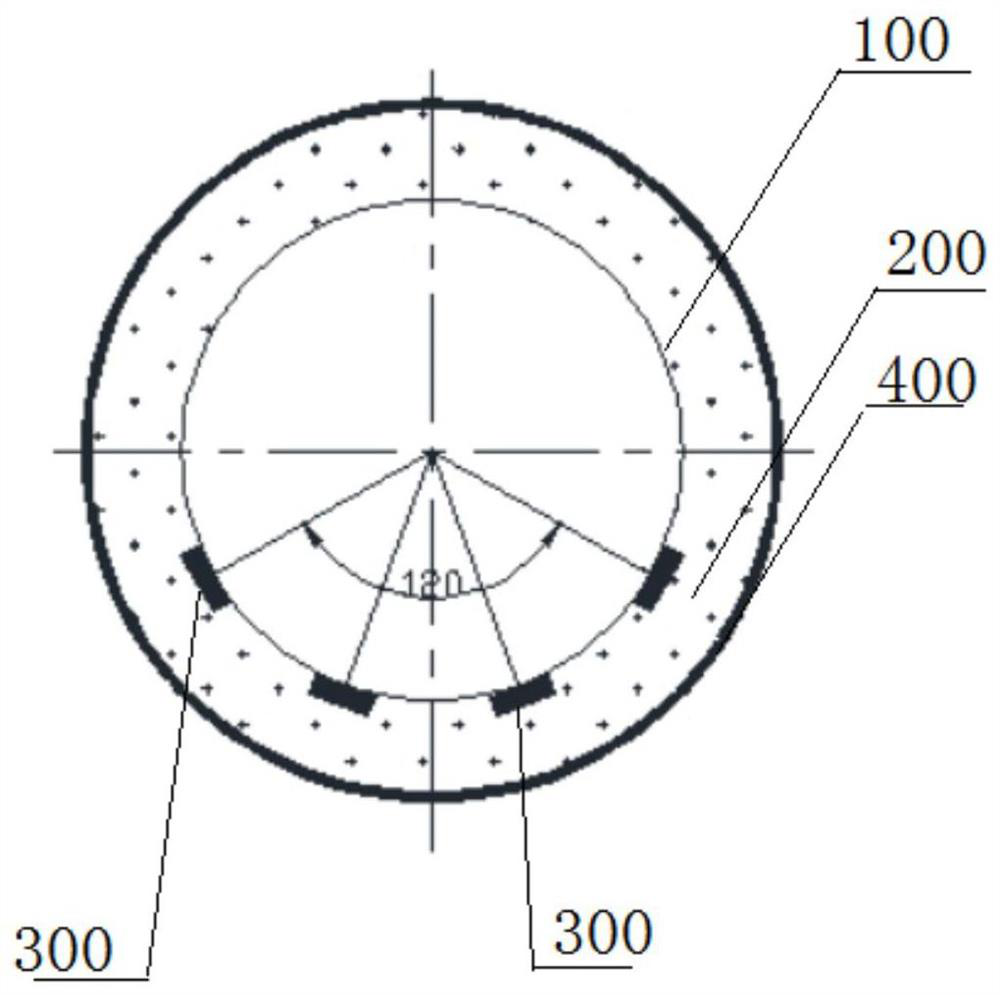

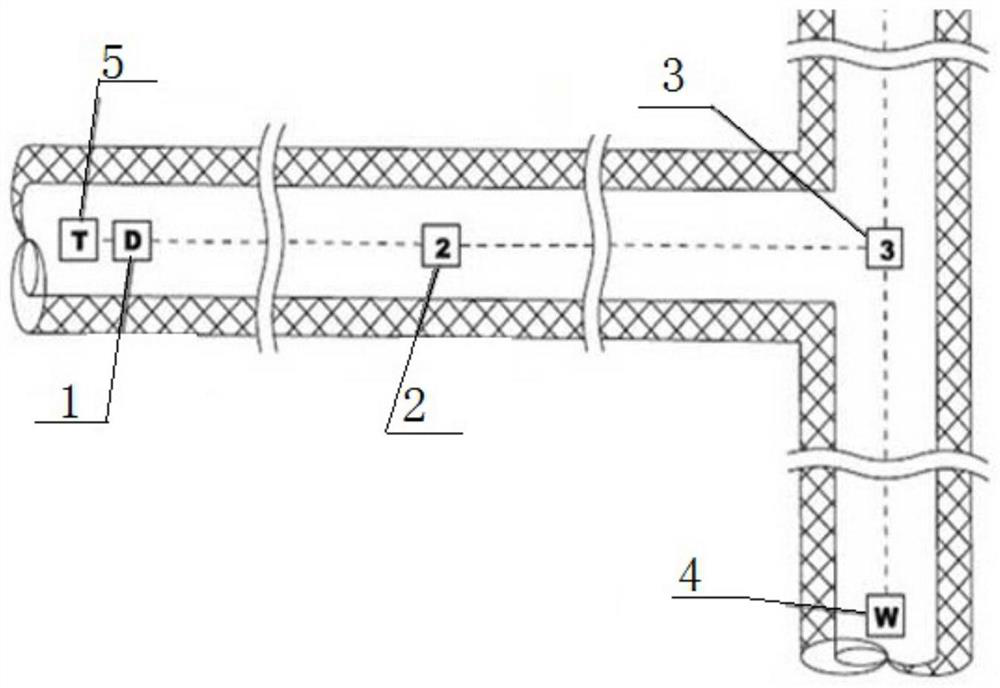

[0089] Molten bisphenol A pipe, medium temperature 156-158°C, ambient temperature 18°C, nominal diameter 200mm, straight pipe length 260m, 12 elbows, each 0.5m, 8 two-way valves, 12 three-way valves , each 0.6 meters.

[0090] Step 1, smoothing the outer surface of the chemical pipeline 100 to be heated, and purging the outer surface of the chemical pipeline 100 .

[0091] Step 2. Since the temperature of the medium in the pipeline is 156-158°C, choose a high-temperature heating cable 300 with a working temperature range of 0-600°C;

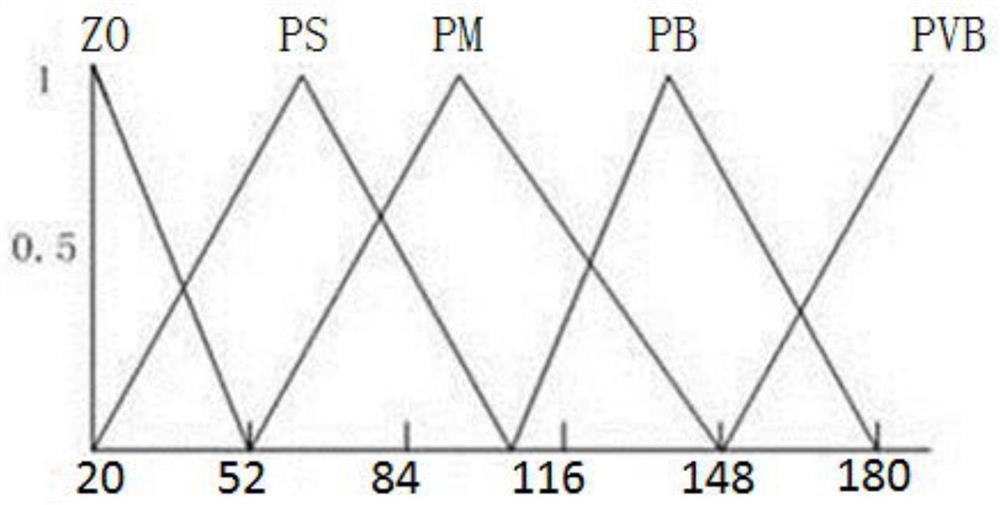

[0092] As shown in Table 1, based on the medium temperature of 156-158°C, the nominal diameter of carbon steel is 200mm, the thickness of the insulation layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com