Manufacturing method of shale cylindrical sample

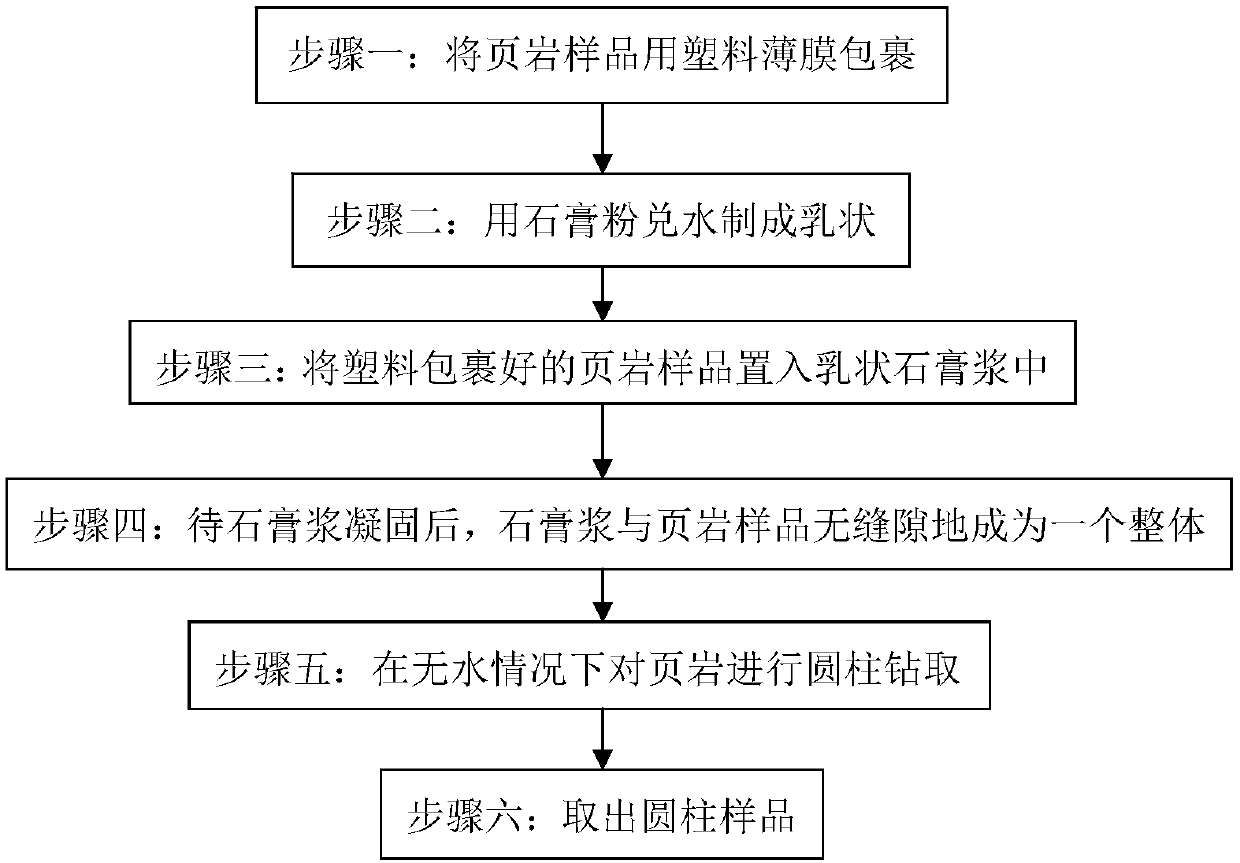

A preparation method and sample technology, applied in the field of preparation of shale cylindrical samples, can solve the problems of cumbersome methods, fragmentation, and difficulty in shale drilling, and achieve the effects of simple operation and short preparation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] In October 2016, the present invention began to be used in Sinopec Wuxi Institute of Petroleum Geology. The shale samples that are difficult to drill by conventional methods have successfully drilled shale cylinders through this method. Ratio and porosity) analysis lays the foundation.

[0046] In summary, the beneficial effects of the present invention are: there is no need to drill cylindrical samples in water, and there is no need to pour concrete outside the original state, which greatly improves the success rate of shale cylindrical sample preparation and avoids polluting rock samples. Effective analysis of shale petrophysical parameters (such as porosity, permeability, etc.) lays a solid foundation. In addition, the invention has the advantages of short preparation cycle, simple operation and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com