Supervision data generation device and supervision data generation method

A data generation and data technology, applied in the direction of length measuring device, reasoning method, database update, etc., can solve the problems of controlling interference, finding control rules, and difficult to achieve control accuracy, so as to achieve the effect of realizing control and high-precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

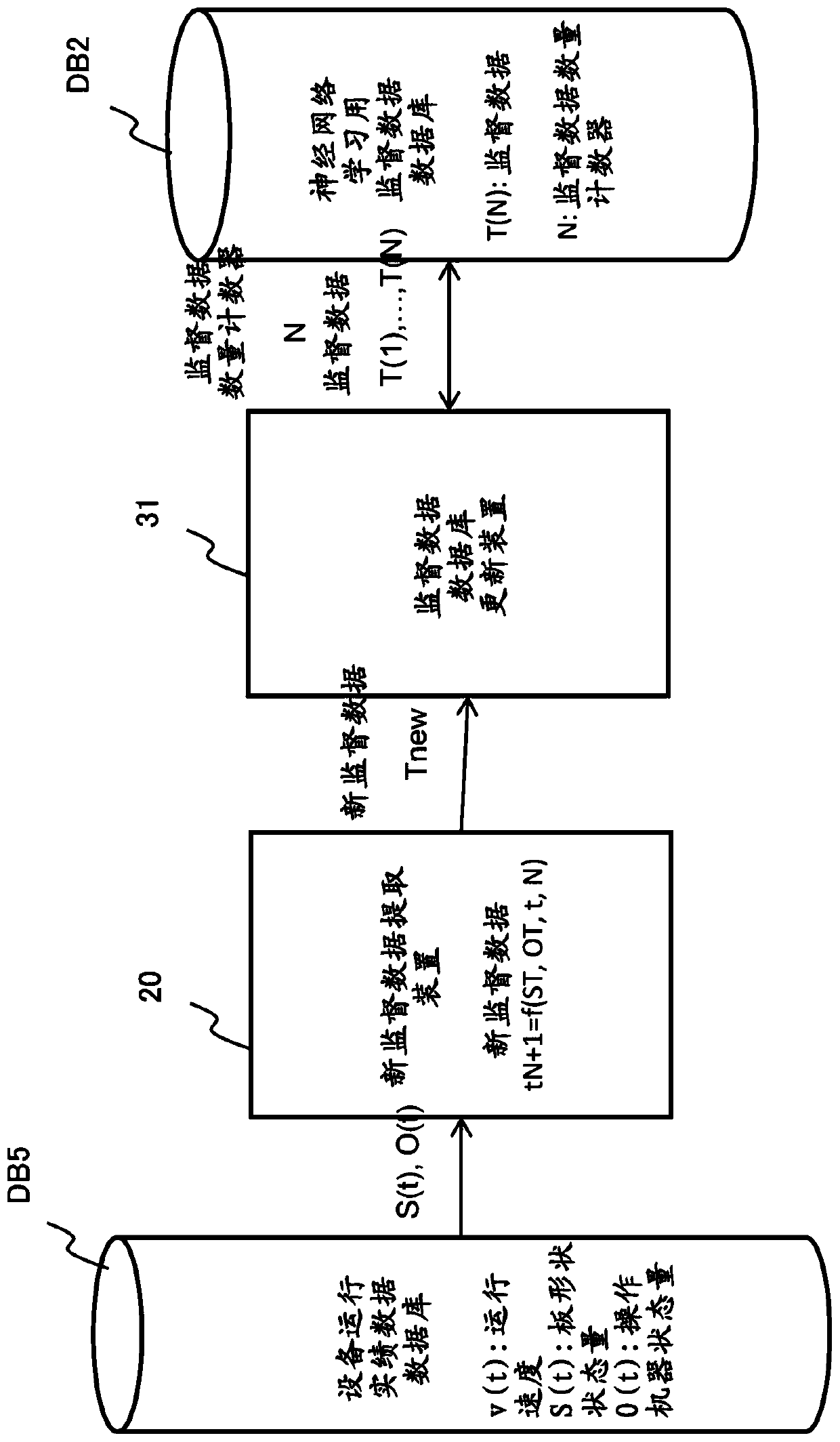

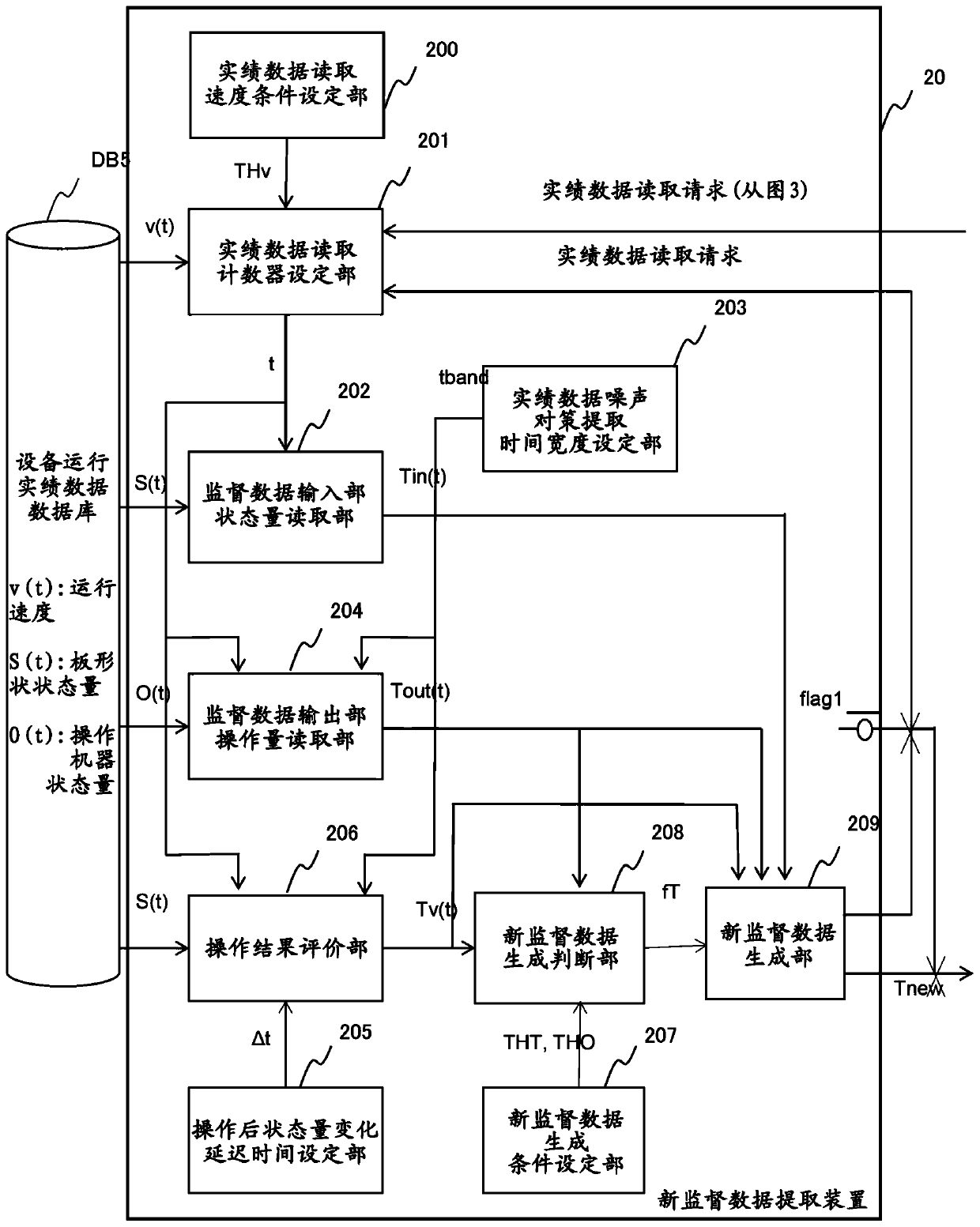

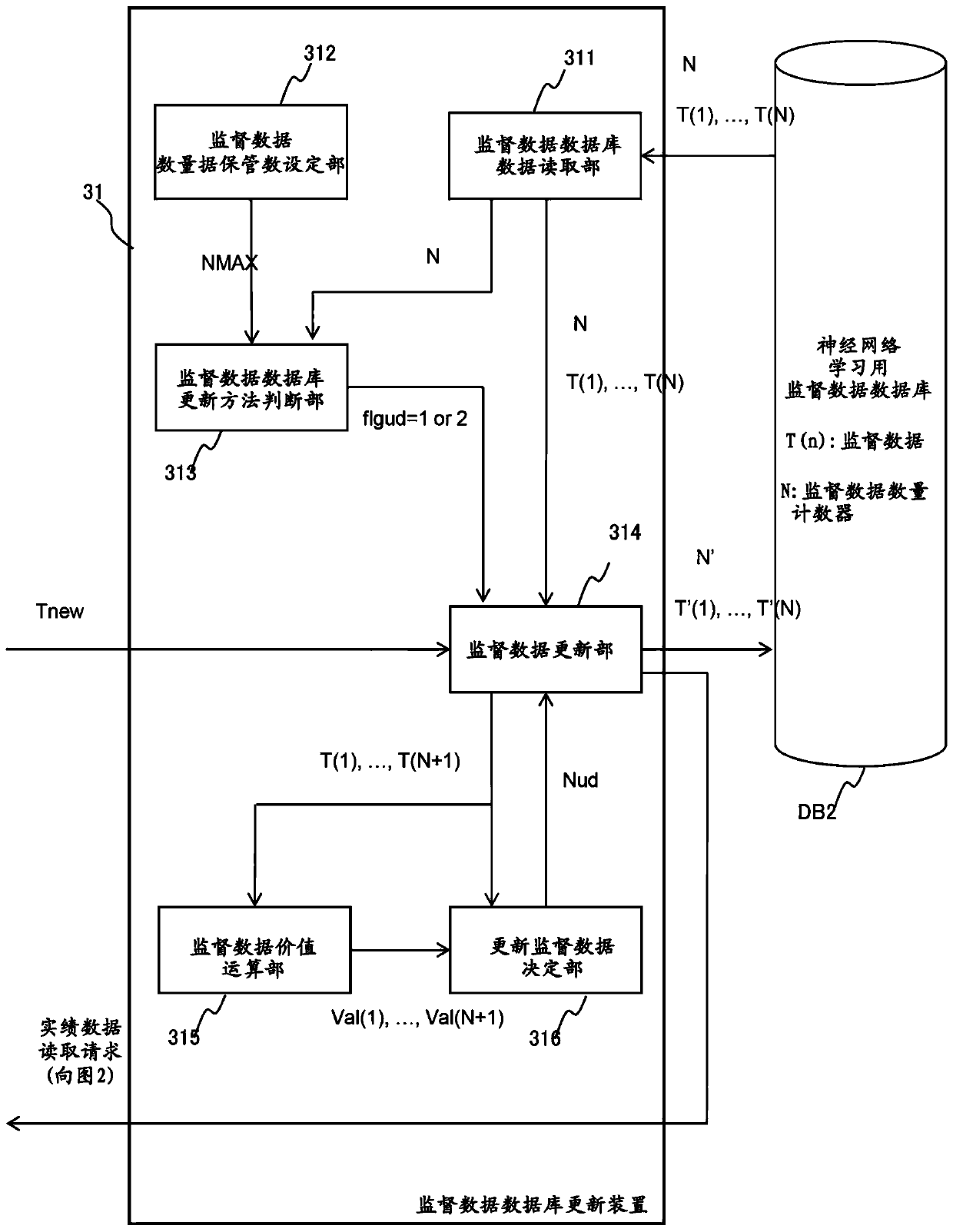

[0039] First, the basic concept included in this embodiment will be described.

[0040] In equipment control, actual phenomena that cannot be modeled, operator's skills based on past experience, etc. are included in past operation performance data of equipment. Therefore, it is effective for optimum facility control to collect past facility operation performance data, extract control rules offline, and perform learning using the extracted control rules as supervisory data. The control rule is information that associates shape output (state quantity) with operation (operation quantity). Here, the implementation procedure for applying the result of offline AI machine learning to an actual machine using supervisory data generated based on pre-accumulated past facility operation performance data is shown below.

[0041] (1) Collect the operation actual performance data of the equipment.

[0042] (2) Extract supervisory data used in machine learning of AI from actual operating pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com