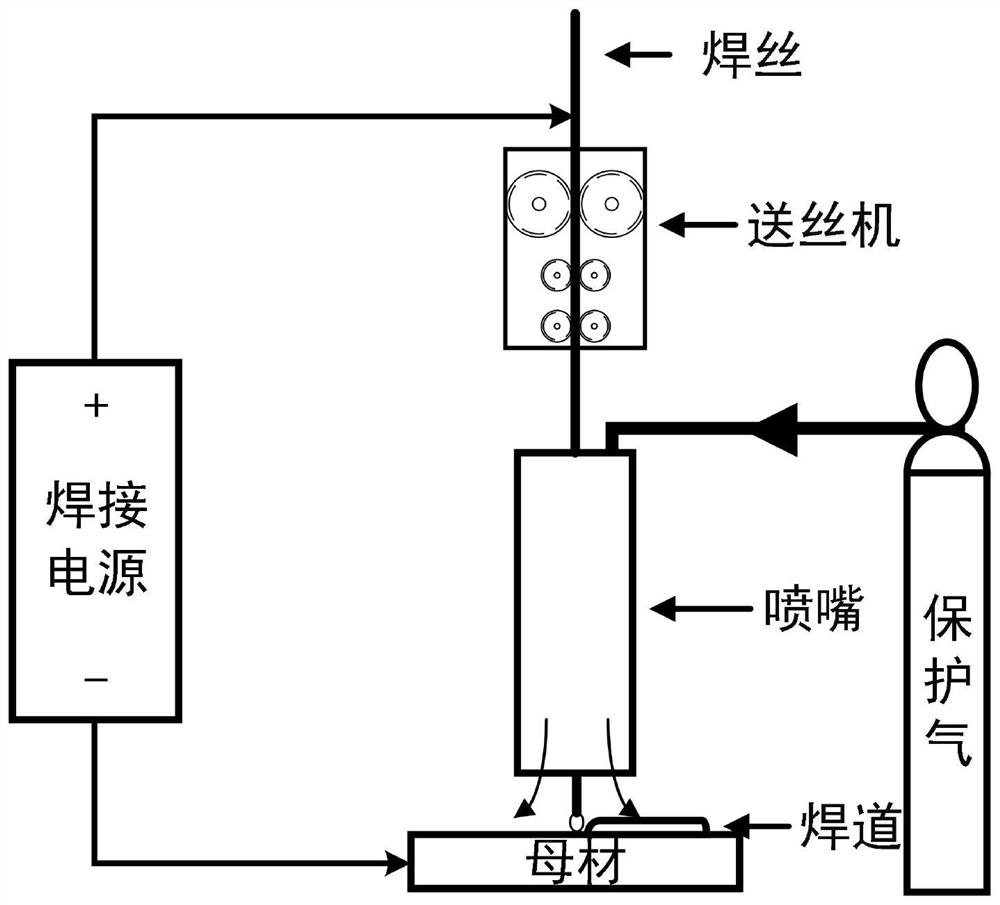

Fusion welding process high-dynamic wire feeding control method based on piezoelectric actuator

A piezoelectric actuator and control method technology, applied in arc welding equipment, process efficiency improvement, manufacturing tools, etc., to achieve the effects of easy implementation, control, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

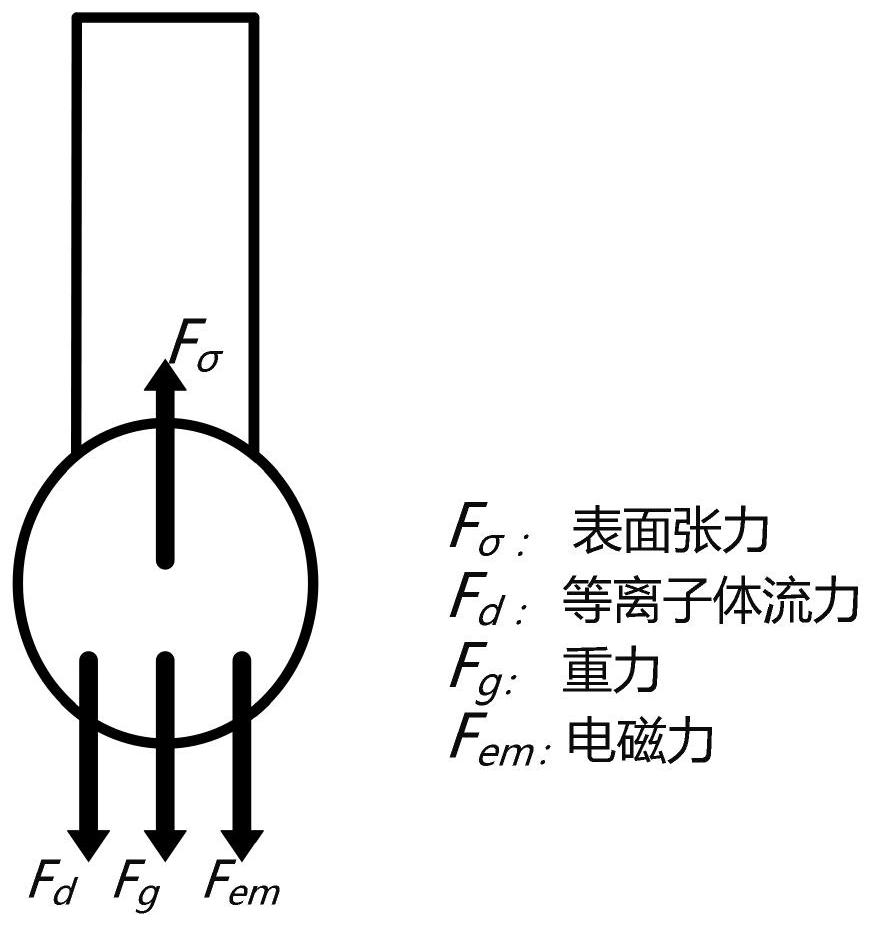

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

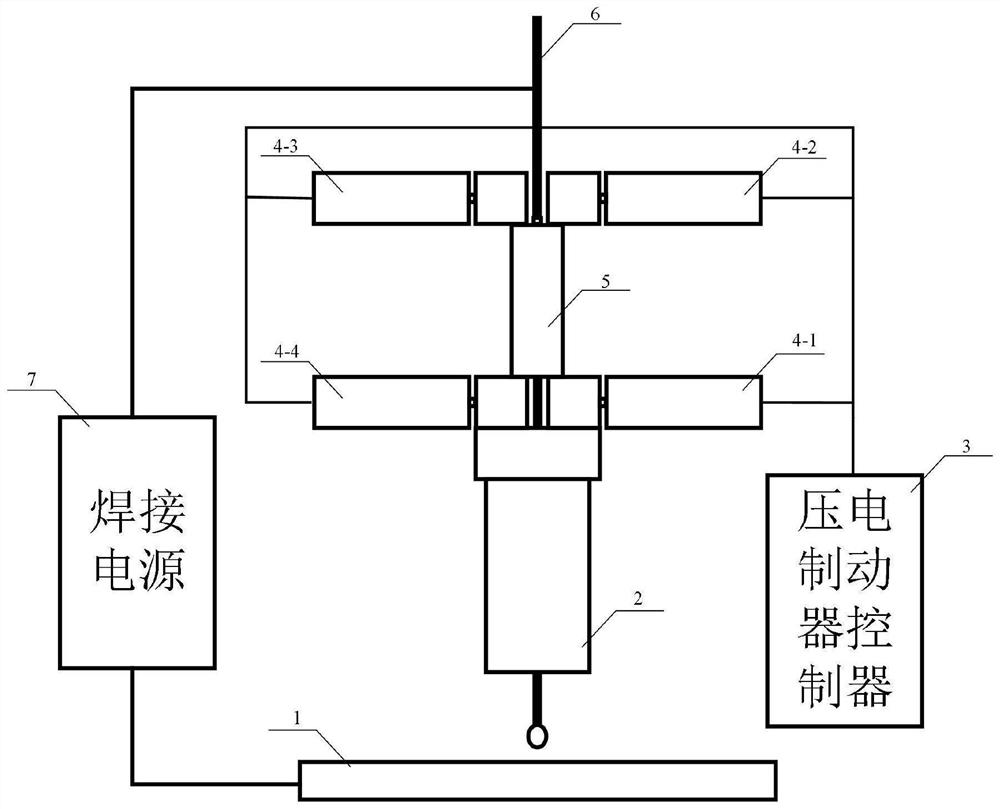

[0024] The apparatus employed in the present embodiment includes: welding workpiece 1, arc welding torch 2, piezoelectric actuator controller 3, bottom radial actuator 4-1&4-4, top radial actuator 4-2&4-3, axial actuator 5, welding wire 6, welding power supply 7. The 4-2&4-3 piezo actuator combination completes the butt welding wire locking, and the 4-1&4-4 and 5 axial actuators complete the retraction of the welding wire; and the stirring action process is the top radial actuator 4-2&4-3 locking welding wire, and the 4-1 and 4-4 actions achieve the effect of stirring / excitation molten pool.

[0025] Welding wire 6 is an ER50-6 carbon steel argon arc welding wire with a diameter of 0.8mm. as Figure 4 as shown, t 0 -Δt 1 When the piezoelectric actuator acts on the pre-weld wire is fed normally and the wire feed speed is equal to the instantaneous speed at the end of the weld wire; the periodicity is t 0 At the moment, the top radial piezo actuator P1 can realize the transient lockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com