A straw returning treatment device

A processing device and straw technology, applied in agricultural machinery and implements, agriculture, cutters, etc., can solve the problems of rotary blade resistance, soil air leakage, large transmission mechanism, etc., to improve crushing efficiency and avoid dust Flying, to ensure the effect of crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

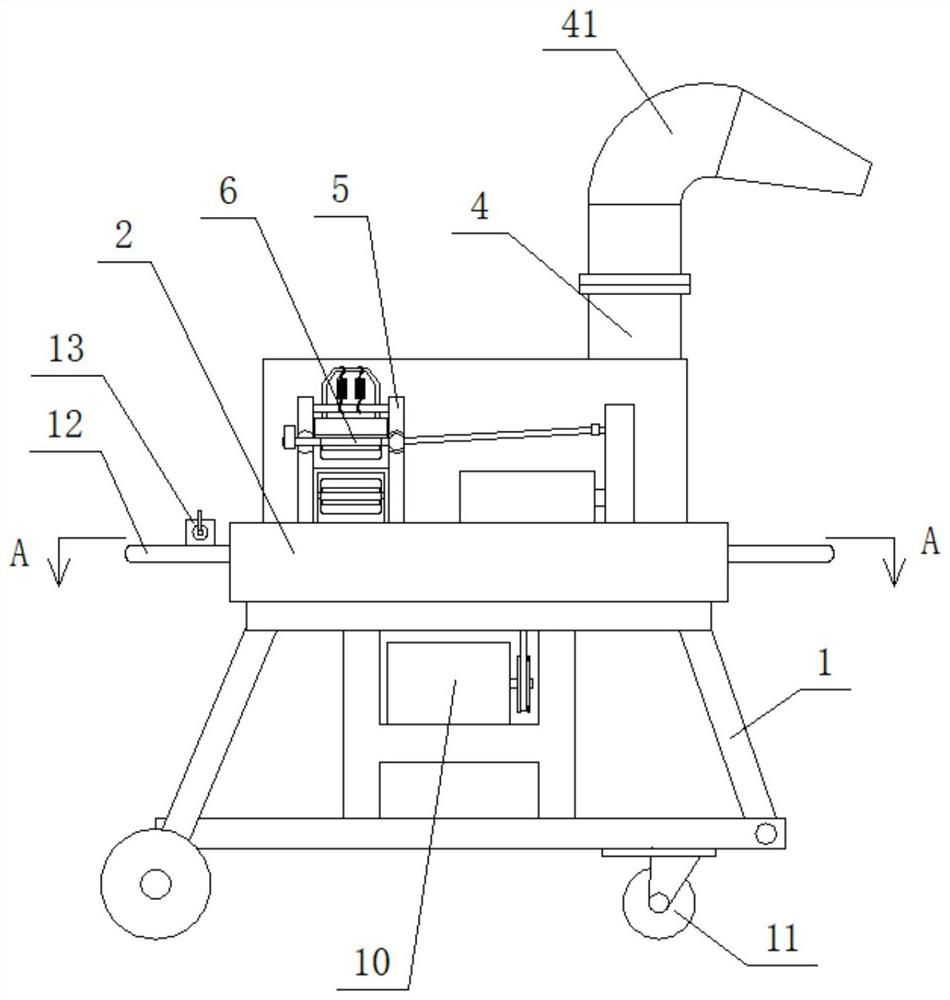

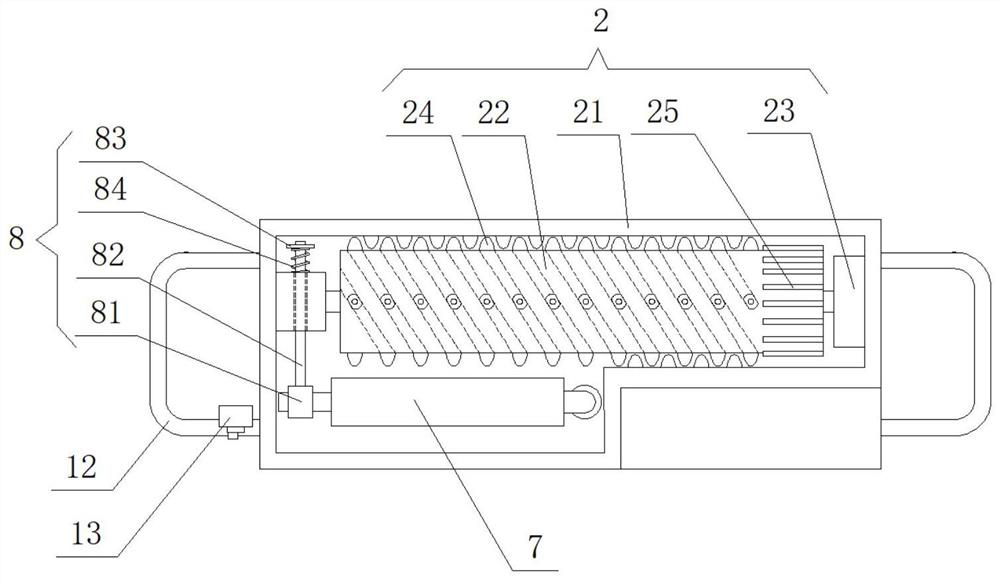

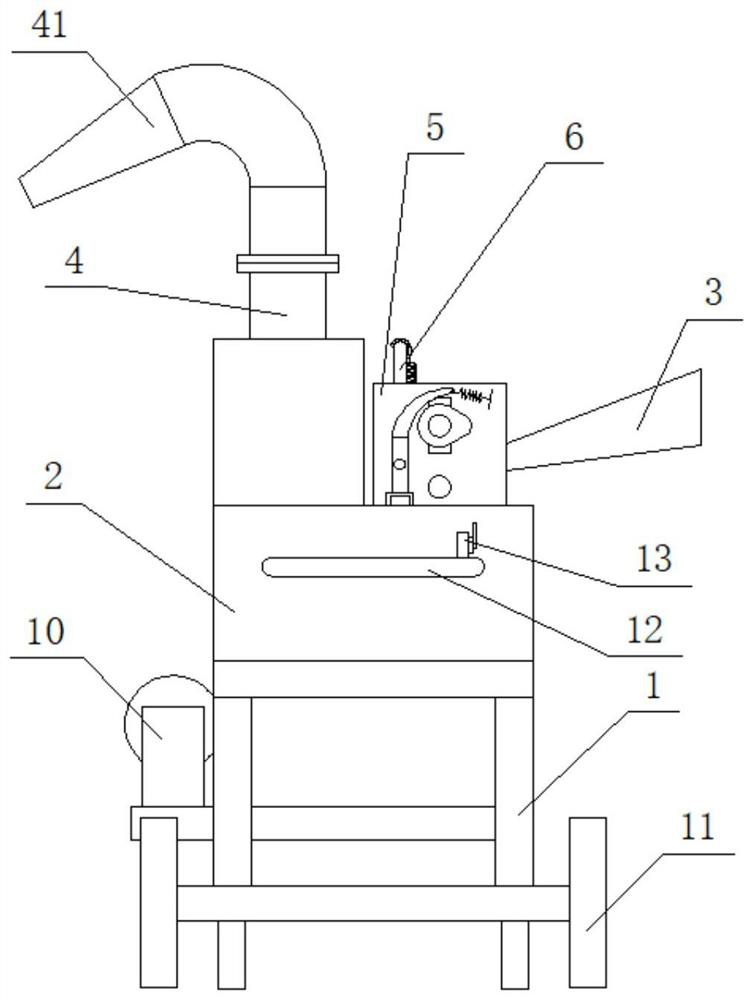

[0028] Such as Figure 1 to Figure 5 As shown, the straw returning treatment device provided in this embodiment includes a frame 1, a support wheel set 11 that drives the frame 1 to move, and a crushing mechanism 2 installed on the frame 1. The crushing mechanism 2 includes a housing 21 and The crushing roller 22 installed in the housing 21 is rotatable. The inner wall of the housing 21 and the ring surface of the crushing roller 22 are processed with crushing teeth 24 that cooperate with each other. A plurality of crushing teeth 24 are arranged in a spiral shape along the processing direction. , so that the straw can be pushed to move to the other end along the crushing teeth 24 while the straw is crushed. A discharge pipe 4 for the straw to leave the housing 21 is processed, and the crushing roller 22 below the discharge pipe 4 is equipped with a winnowing sheet 25 that drives the straw to be thrown out. The arc tube 41.

[0029] A bracket 5 is provided between the feed ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com