A filling machine for filling joint ointment

A filling machine and joint technology, applied in the directions of ointment delivery, injection device, organic active ingredients, etc., can solve problems such as inability to treat joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The joint ointment in Example 1 contains the following components: Rhizoma Rhizoma Rhizoma Rhizoma Rhizome, Turtle Gum, Eucommia, Xu Changqing, Psoralen Extract, Glucosamine Hydrochloride, Chondroitin Sulfate and Green Lipped Mussel Powder; And the quality of the above components is respectively: drynaria rhizome 15 grams, grass 15 grams, turtle glue 10 grams, Eucommia ulmoides 15 grams, Xu Changqing 15 grams, psoralen extract 15 grams, glucosamine hydrochloride 20 grams, Chondroitin sulfate 12 grams, green lipped mussel powder 5 grams.

[0040] After the joint ointment formed by the raw materials of the above components and quality is filled in the packaging tube 50, it forms a specification of 120g together with the packaging tube 50. The joint ointment of this specification is suitable for the consumption of pets for 2-3 months, forming a therapeutic cycle.

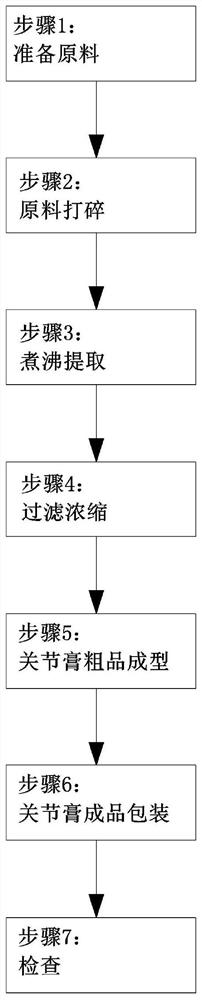

[0041] At the same time, the drynariae drynariae, shenjincao, turtle gum, Eucommia ulmoides, Xu Changqing an...

Embodiment 2

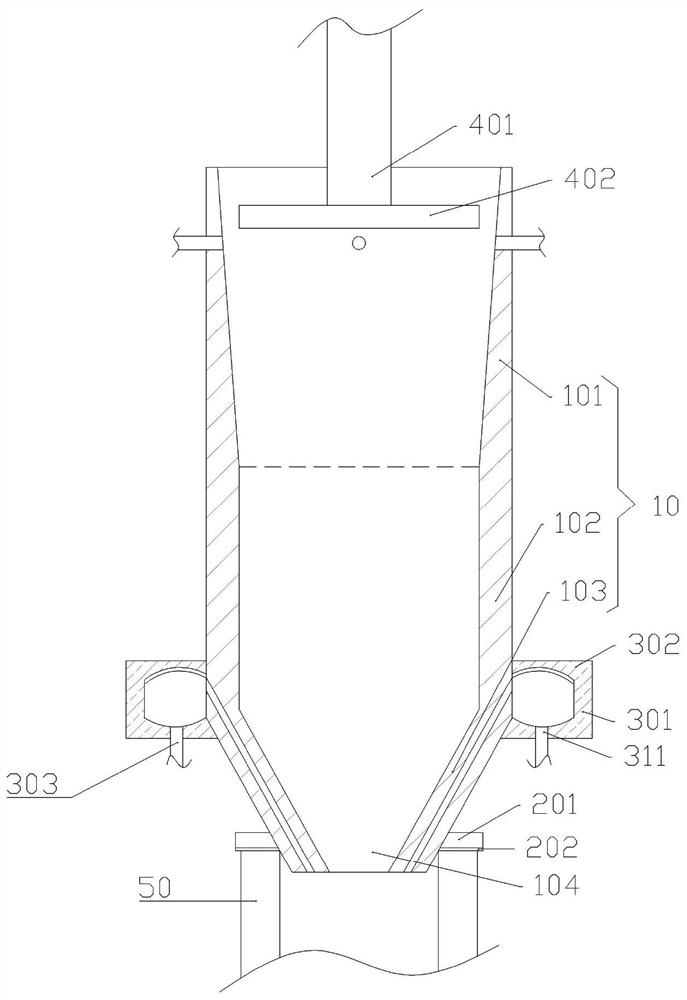

[0051] The difference between embodiment 2 and embodiment 1 is that embodiment 2 also includes basic figure 2 The shown filling machine includes a filling head 10, a backflow detection mechanism, a sealing mechanism and a pressing filling mechanism.

[0052] as attached figure 2 The filling head 10 shown includes an upper section 101, a middle section 102, and a lower section 103. The bottom of the lower section 103 of the filling head 10 is provided with a discharge port 104, and the discharge port 104 section of the filling head 10 is a circular platform shrinking from top to bottom. shape, the discharge port 104 of the filling head 10 can be inserted into the port at the upper end of the packaging tube 50; The inner wall of the middle section 102 of the filling head 10 has a smooth transition; the pressing and filling mechanism includes a pressure rod 401 and a pressure plate 402 that move up and down. 10, and the pressure plate 402 is in sliding sealing contact with th...

Embodiment 3

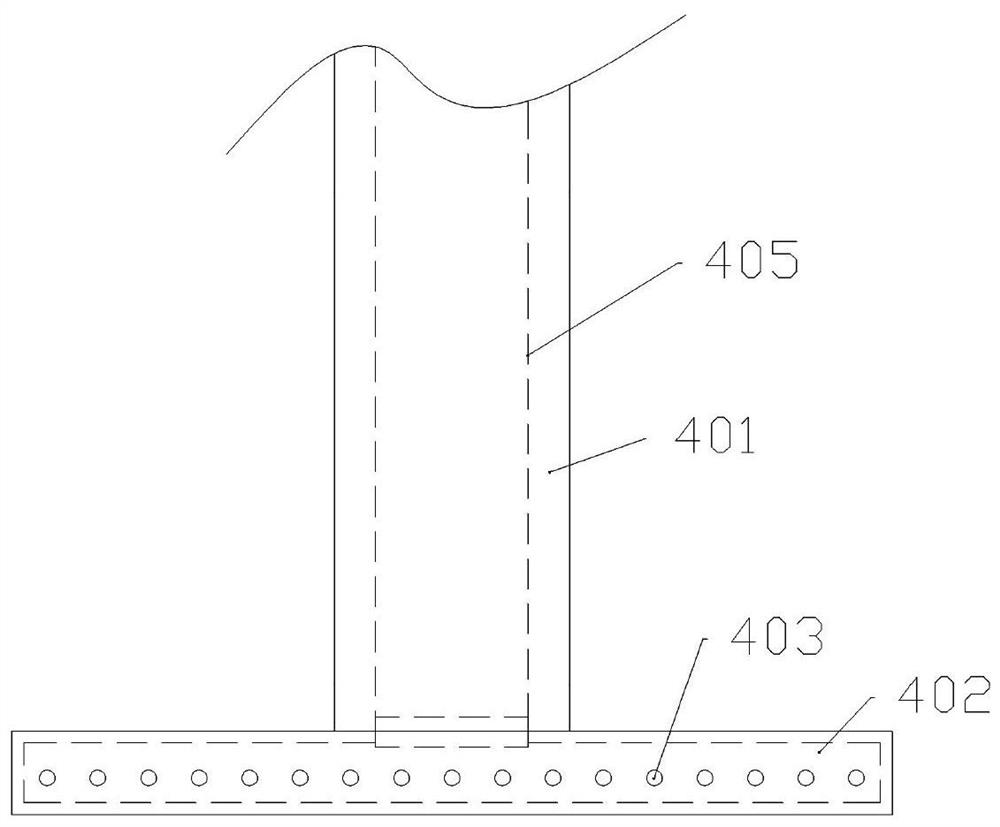

[0059] The difference between embodiment 3 and embodiment 2 is that embodiment 3 is basically as attached image 3 And attached Figure 4 As shown, a water cavity 405 is also set in the pressure rod 401 and the pressure plate 402, a number of first cleaning holes 403 are set on the side of the pressure plate 402, and a number of circumferentially arranged second cleaning holes 403 are set on the lower surface of the pressure plate 402. The cleaning hole 404, the extension line of the axis of the second cleaning hole 404 can be in contact with the inner wall of the middle section 102 of the filling head 10, and the lower end of the second cleaning hole 404 is opposite to the inner wall of the filling head 10, which is convenient for spraying from the second cleaning hole 404. The discharged water can impact on the inner wall of the middle section 102 of the filling head 10 to clean the inner wall of the middle section 102 of the filling head 10 .

[0060] When the filling head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com