A plasma powder surfacing device for fully utilizing alloy powder

An alloy powder and plasma technology is applied in the field of ion powder surfacing equipment, which can solve the problems of easy blockage of powder feeding holes, insufficient powder use, and inability to detect in time, and achieves the effect of ensuring powder output stability and full utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

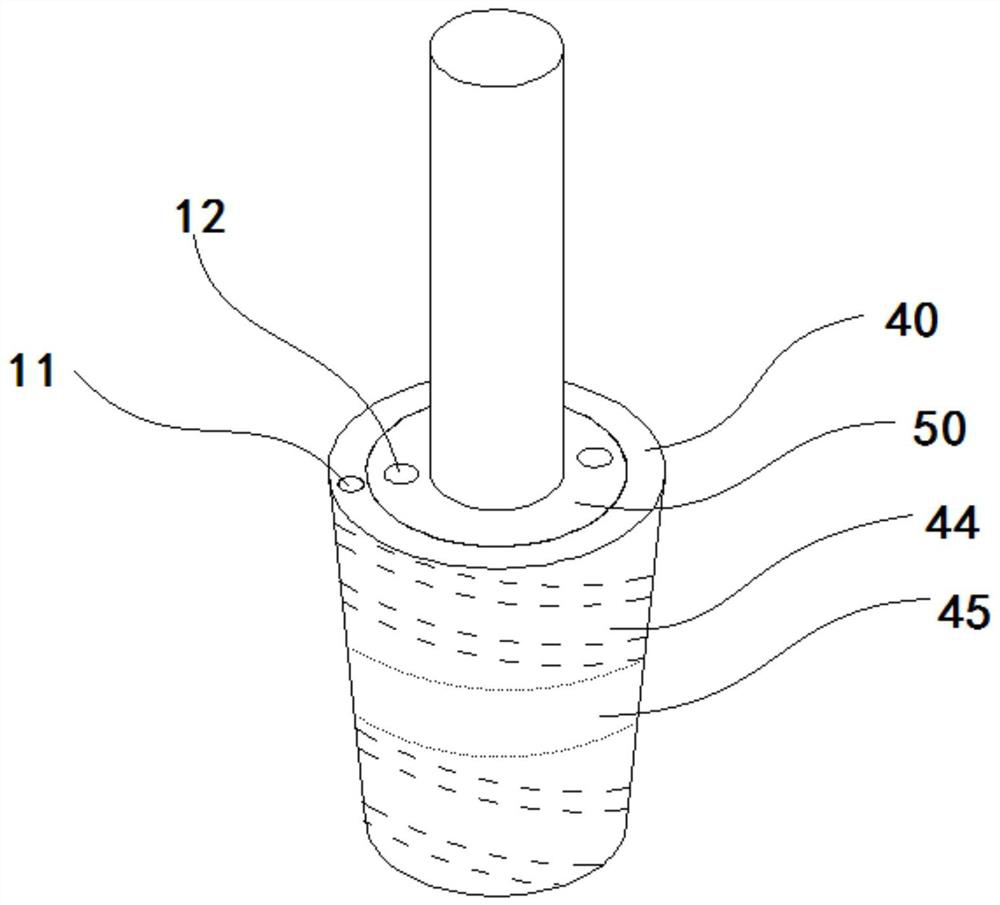

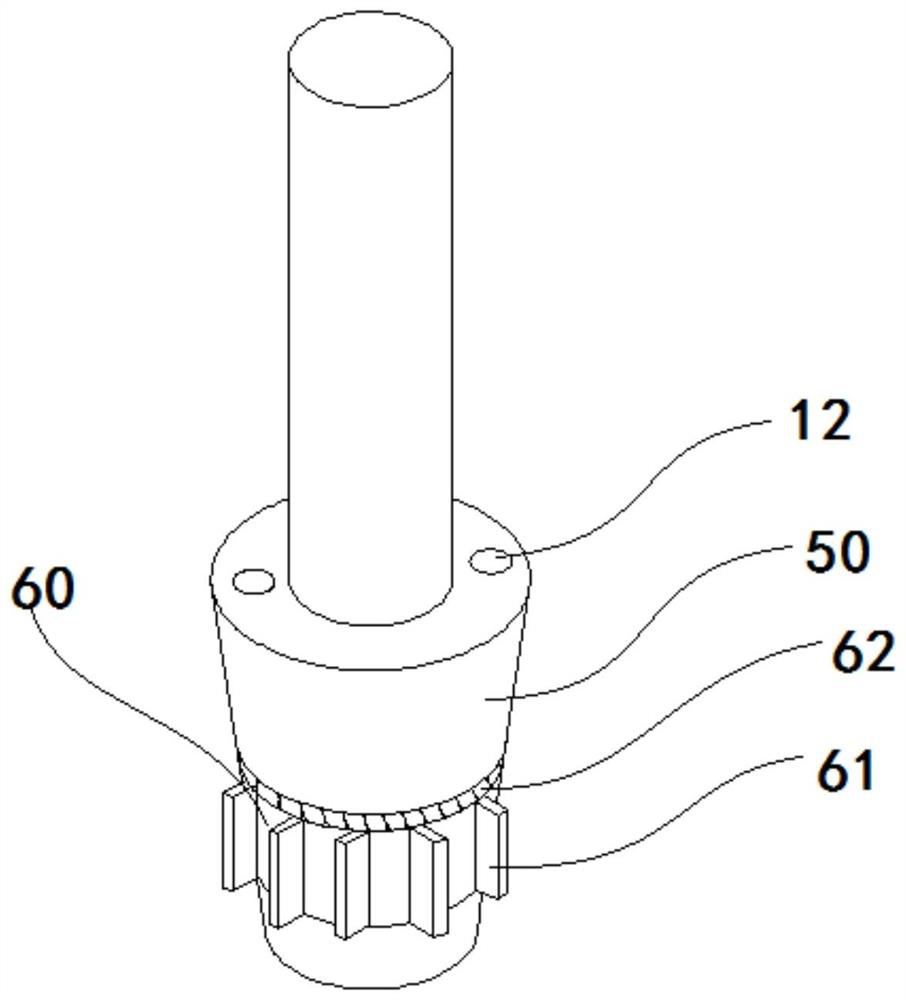

[0021] as attached figure 1 Shown, a kind of plasma powder surfacing device that alloy powder makes full use of, comprises, welding torch body 100; This welding torch body 100 comprises the front torch body 10 and rear torch body 20 of detachable fixed connection; Front torch body 10 and rear torch An insulator 30 is arranged between the bodies 20 and can be locked by a locking ring;

[0022] Between the front gun body 10 and the rear gun body 20, a circulating cooling water channel 13, a protective gas channel 11, an ion gas channel and a powder feeding channel 12 communicated with each other are provided; One hole, the second hole corresponding to the powder feeding channel 12, the third hole for circulating cooling water to pass through, and the central hole for ion gas to pass through; The plasma powder surfacing machine has a welding unit connected to the tungsten electrode of the welding gun body, a cooling water tank connected to the circulating cooling water channel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com