System and method for automatically cleaning internal combustion locomotive radar

An internal combustion locomotive and automatic cleaning technology, which is applied to locomotives with internal combustion engines, locomotive propulsion methods, and locomotives with gas turbines, etc., can solve problems such as energy waste, radar burnout, and large heating power requirements, and achieve the effect of saving system resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following describes the embodiments of the present invention in detail in conjunction with specific embodiments and with reference to the accompanying drawings.

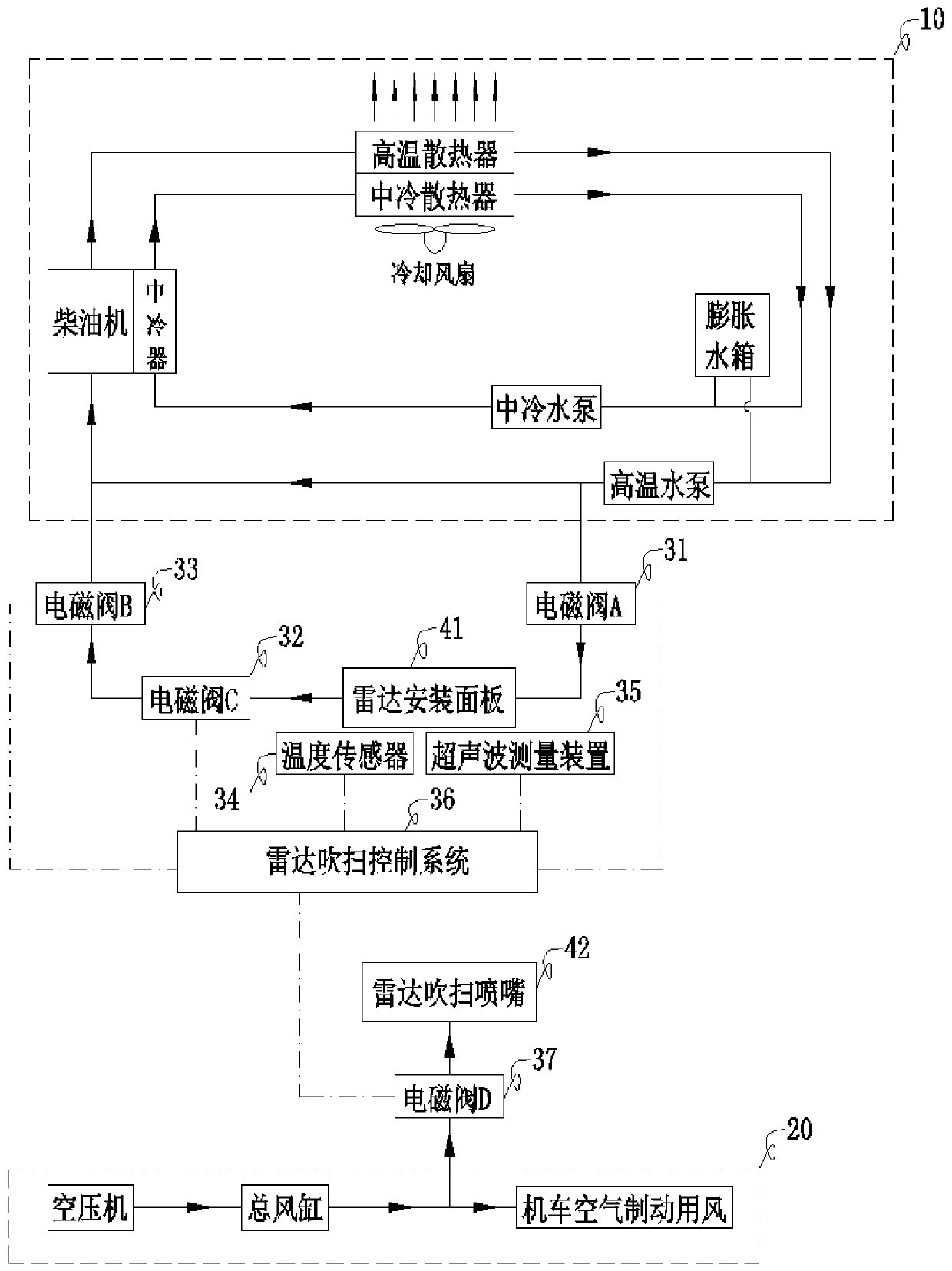

[0054] Such as figure 1 As shown, the main components of the diesel engine cooling system 10 are simply shown. The diesel engine cooling system 10 on the diesel locomotive makes the high temperature water heated by the diesel engine dissipate the heat into the atmosphere through the high temperature radiator and cooling fan to cool the high temperature water temperature Afterwards, the temperature of the high-temperature water has been kept at about 50℃~90℃ during the operation of the locomotive. The diesel engine cooling system 10 used in the present invention is a common diesel engine cooling system in the prior art. Therefore, the structure and the connection relationship of components are not described in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com