A solid nano-dispersion absorbing material

A nano-dispersion and wave-absorbing material technology, which is applied in the field of wave-absorbing materials, can solve problems such as large filling ratio, high density, and narrow absorption frequency band, and achieve the effect of small filling amount, good effect, and wide wave-absorbing frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

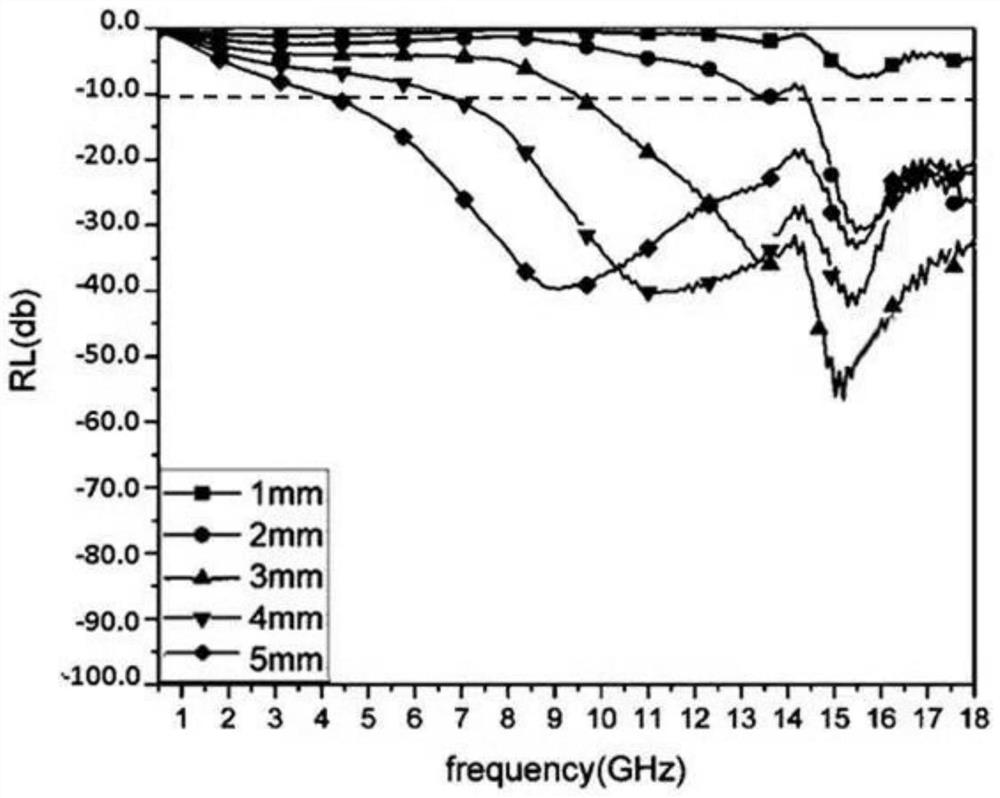

[0022] Add 20g of gum arabic to 200g of water, stir to dissolve it, then add 5g of magnetosomes and 5g of carbon fiber to it, and use a high-speed shearing machine with a power of 1200W and a pressure of 0.8MPa to make it into a suspension state. The resulting suspension was homogenized by a high-pressure homogenizer at a pressure of 1000 bar, and then spray-dried. The air inlet temperature of the spray-drying was 180° C., and the feed rate was 60 kg / h to obtain a solid nano-dispersion wave-absorbing material.

[0023] The absorbing material is dispersed in paraffin, wherein the mass fraction of the absorbing material is 30%, and the absorbing material / paraffin mixture is pressed into a ring with an outer diameter of 7 mm, an inner diameter of 3 mm, and a thickness of 3 mm. Using a vector network analyzer to test the dielectric constant and permeability of the absorbing material, the lowest reflection loss (RL min ) at 3mm is -55.2dB, when the thickness is 3mm, the frequency b...

Embodiment 2

[0025] Add 20g of gum arabic to 250g of water, stir to dissolve it, then add 4g of magnetosomes and 4g of carbon fibers to it, and use a high-speed shear to make it into a suspension state at a power of 1200W and a pressure of 0.8MPa. The resulting suspension was homogenized by a high-pressure homogenizer at a pressure of 1000 bar, and then spray-dried. The air inlet temperature of the spray-drying was 180° C., and the feed rate was 60 kg / h to obtain a solid nano-dispersion wave-absorbing material.

[0026] The absorbing material is dispersed in paraffin, wherein the mass fraction of the absorbing material is 30%, and the absorbing material / paraffin mixture is pressed into a ring with an outer diameter of 7 mm, an inner diameter of 3 mm, and a thickness of 3 mm. Using a vector network analyzer to test the dielectric constant and permeability of the absorbing material, the lowest reflection loss (RL min ) is -35.2dB when the thickness is 3mm, and the frequency bandwidth in whic...

Embodiment 3

[0028] Add 20g of gum arabic to 200g of water, stir to dissolve it, then add 4g of magnetosomes and 4g of carbon fibers to it, and use a high-speed shear to make it into a suspension state at a power of 1200W and a pressure of 0.8MPa. The resulting suspension was homogenized by a high-pressure homogenizer at a pressure of 1000 bar, and then spray-dried. The air inlet temperature of the spray-drying was 180° C., and the feed rate was 60 kg / h to obtain a solid nano-dispersion wave-absorbing material.

[0029] The absorbing material is dispersed in paraffin, wherein the mass fraction of the absorbing material is 30%, and the absorbing material / paraffin mixture is pressed into a ring with an outer diameter of 7 mm, an inner diameter of 3 mm, and a thickness of 3 mm. Using a vector network analyzer to test the dielectric constant and permeability of the absorbing material, the lowest reflection loss (RL min ) is -39.5dB when the thickness is 3mm, and the frequency bandwidth in whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflection | aaaaa | aaaaa |

| reflection | aaaaa | aaaaa |

| reflection | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com