Household fine-brewed beer machine and beer brewing method

A beer machine and fine brewing technology, applied in the direction of beer fermentation method, beer brewing, biochemical equipment and methods, etc., can solve the problems of low degree of automation, incomplete data recording, waste, etc., and achieve high alcohol content and taste, The effect of high degree of automation and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

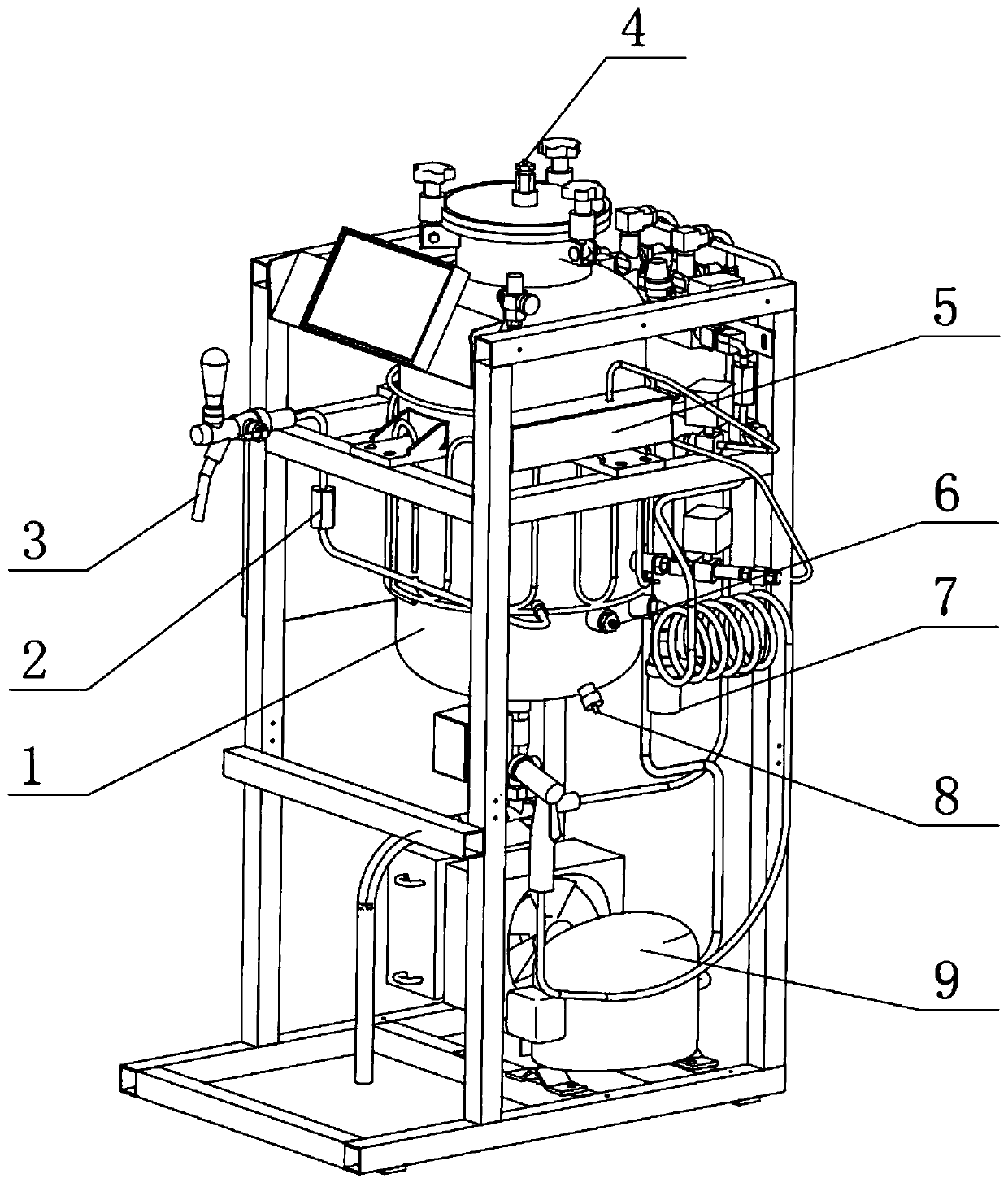

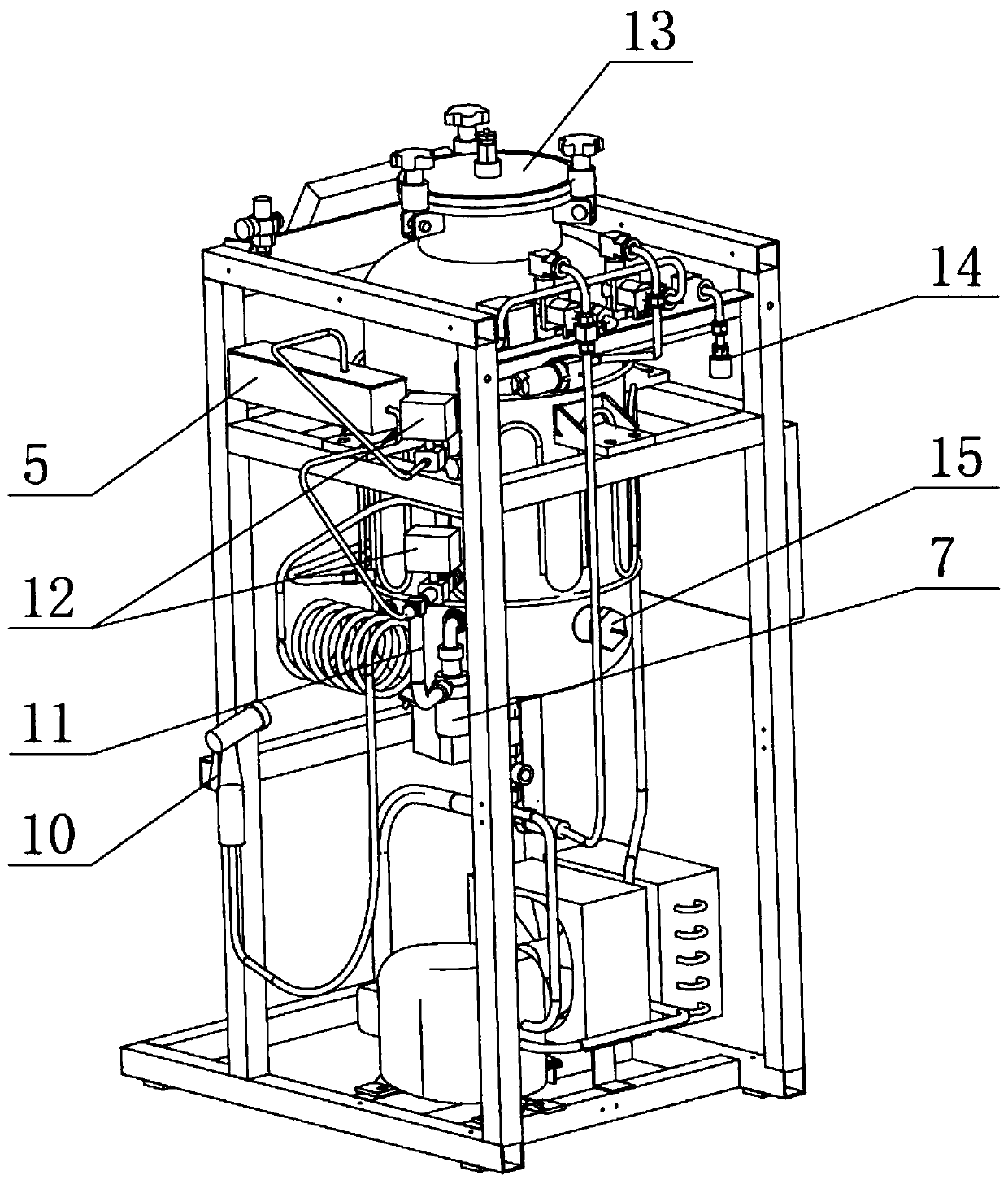

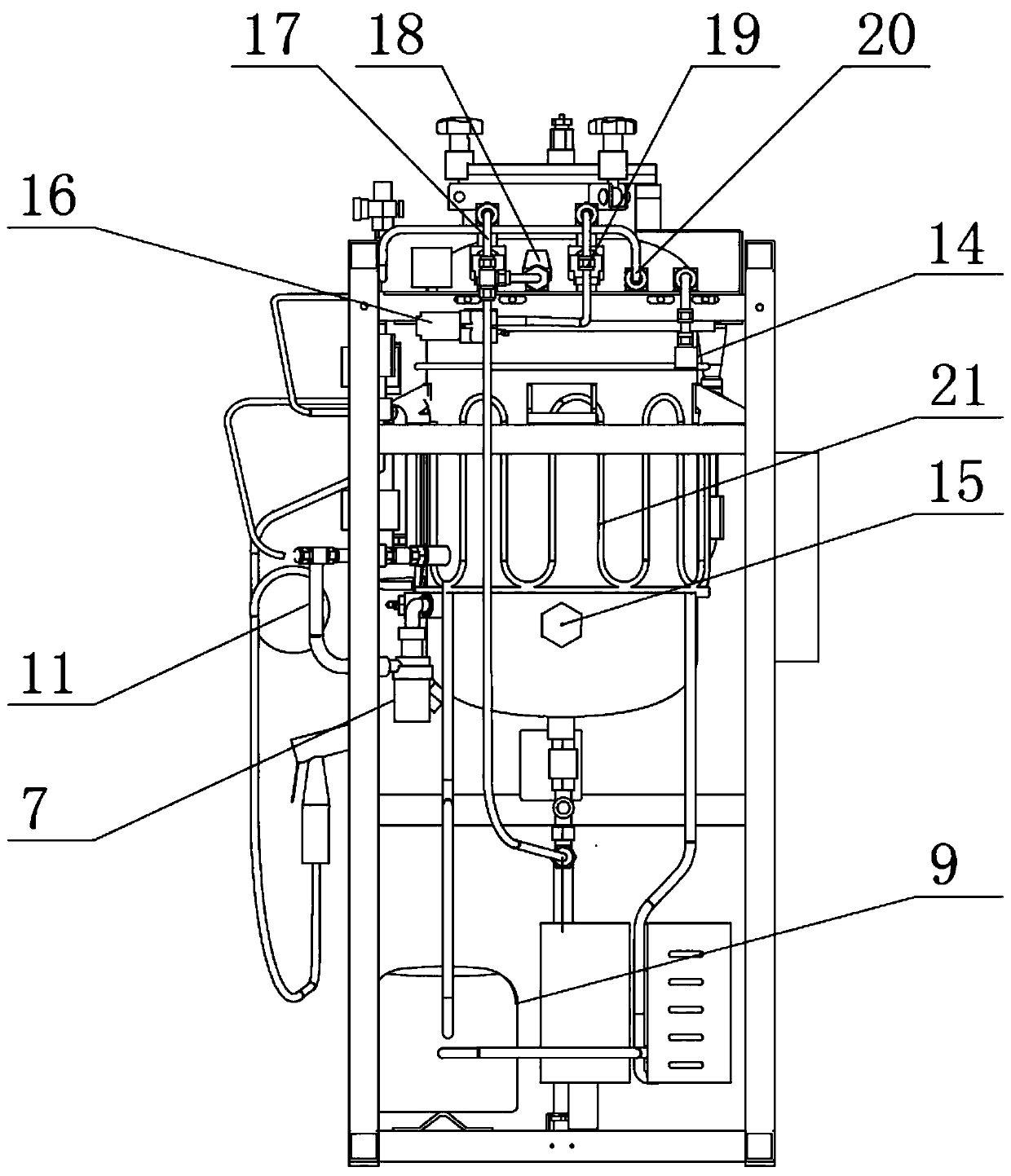

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0049] Such as Figure 1-5 As shown, a household craft beer machine includes a fermenter 1, and the fermenter 1 is provided with a feeding port and a beer outlet, and is characterized in that the device also includes:

[0050] Refrigeration system, the refrigeration system includes a refrigeration part and an internal circulation part, the refrigeration part includes a compressor refrigeration device 9 and a cooling coil 21 coiled on the fermenter 1, and the cooling coil 21 conducts heat to the sample solution in the fermenter 1 Refrigeration; the internal circulation part includes a circulation pump 7 and an internal circulation pipeline to promote the circulation of the sample solution;

[0051] Pressure testing device 14, pressure testing device 14 comprises air pressure sensor, monitors the air pressure in fermentor 1 in real time;

[0052] Oxygen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com