Preparing method of digital printing shading fabric

A digital inkjet and cloth technology, applied in the field of advertising materials, can solve the problems of inconvenient frame exhibition, inelastic product feel, poor shading performance, etc., and achieve the effect of stable picture size, improved shading performance, and high shading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

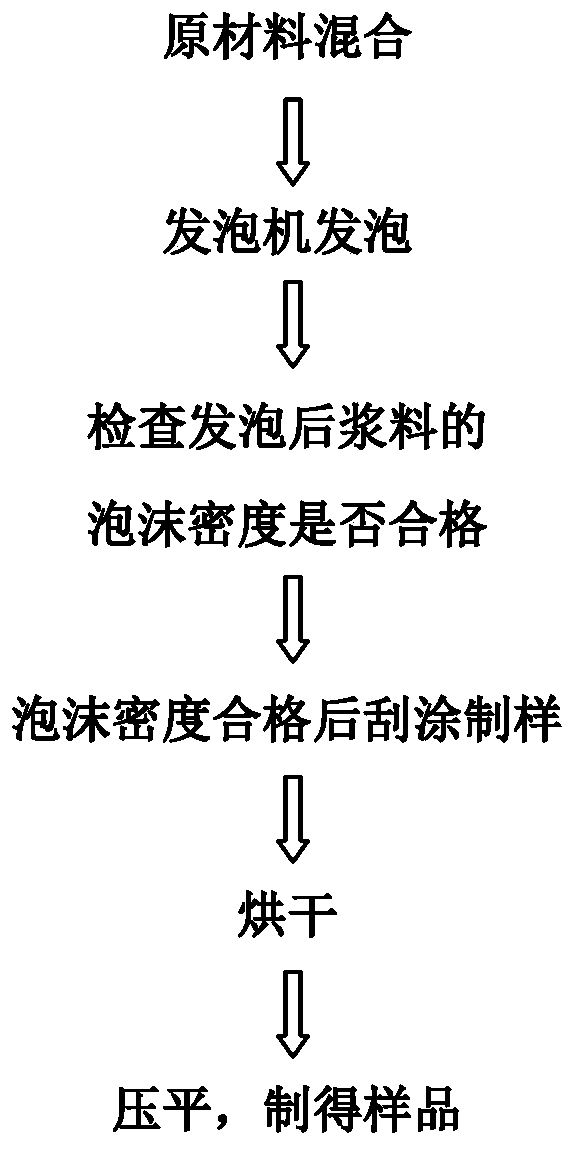

[0034] A preparation method for digital inkjet shading cloth, comprising the steps of:

[0035] (1) Pretreatment of warp knitted fabric:

[0036] Arrange the warp knitting in the direct injection slurry for padding, after the padding is completed, bake to obtain the cloth 1; the two sides of the cloth 1 are respectively marked as the A side and the B side;

[0037] The direct injection slurry is a mixture of an anti-swimming agent and a penetrating agent with a mass ratio of 9:1, and the baking temperature is 150° C., and the time is 1.5 minutes;

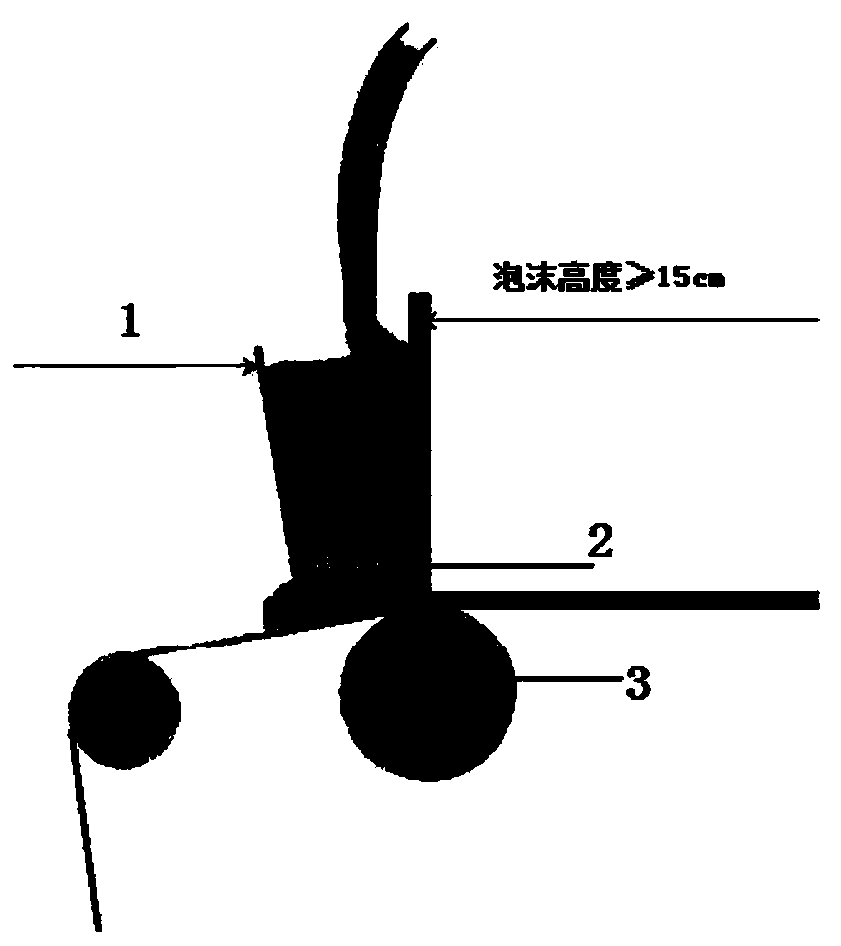

[0038] (2) Mix 100 parts of water-based acrylic emulsion, 20 parts of titanium dioxide, 25 parts of foam stabilizer, 3 parts of crosslinking agent, 35 parts of flame retardant, 30 parts of filler, and 5 parts of anti-sticking and wear-resistant materials to prepare a uniform White slurry with a viscosity of 3000-4000cps, then adjust the pH to 8.0-8.5 with ammonia water; put it into a foaming machine for foaming, set the parameters ...

Embodiment 2

[0042] A preparation method for digital inkjet shading cloth, comprising the steps of:

[0043] (1) Pretreatment of warp knitted fabric:

[0044] Arrange the warp knitting in the direct injection slurry for padding, after the padding is completed, bake to obtain the cloth 1; the two sides of the cloth 1 are respectively marked as the A side and the B side;

[0045] The direct injection slurry is a mixture of an anti-swimming agent and a penetrating agent with a mass ratio of 9:1, and the baking temperature is 120° C., and the time is 2 minutes;

[0046] (2) Mix 100 parts of water-based acrylic emulsion, 15 parts of titanium dioxide, 20 parts of foam stabilizer, 2 parts of crosslinking agent, 30 parts of flame retardant, 25 parts of filler, and 5 parts of anti-sticking and wear-resistant materials to prepare a uniform White slurry with a viscosity of 3000-4000cps, then adjust the pH to 8.0-8.5 with ammonia water; put it into a foaming machine for foaming, set the parameters of...

Embodiment 3

[0050] A preparation method for digital inkjet shading cloth, comprising the steps of:

[0051] (1) Pretreatment of warp knitted fabric:

[0052] Arrange the warp knitting in the direct injection slurry for padding, after the padding is completed, bake to obtain the cloth 1; the two sides of the cloth 1 are respectively marked as the A side and the B side;

[0053] The direct injection slurry is a mixture of an anti-swimming agent and a penetrating agent with a mass ratio of 9:1, and the baking temperature is 170° C., and the time is 1 min;

[0054] (2) Mix 100 parts of water-based acrylic emulsion, 25 parts of titanium dioxide, 30 parts of foam stabilizer, 5 parts of crosslinking agent, 40 parts of flame retardant, 35 parts of filler, and 5 parts of anti-sticking and wear-resistant materials to prepare a uniform White slurry with a viscosity of 3000-4000cps, then adjust the pH to 8.0-8.5 with ammonia water; put it into a foaming machine for foaming, set the parameters of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com