Steel slag pervious concrete pile and anti-blocking device and method of concrete pile

A technology of permeable concrete and concrete piles, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of insufficient strength of crushed stone aggregate, occupying land area, etc., achieve good water permeability and expansion, save investment, The effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

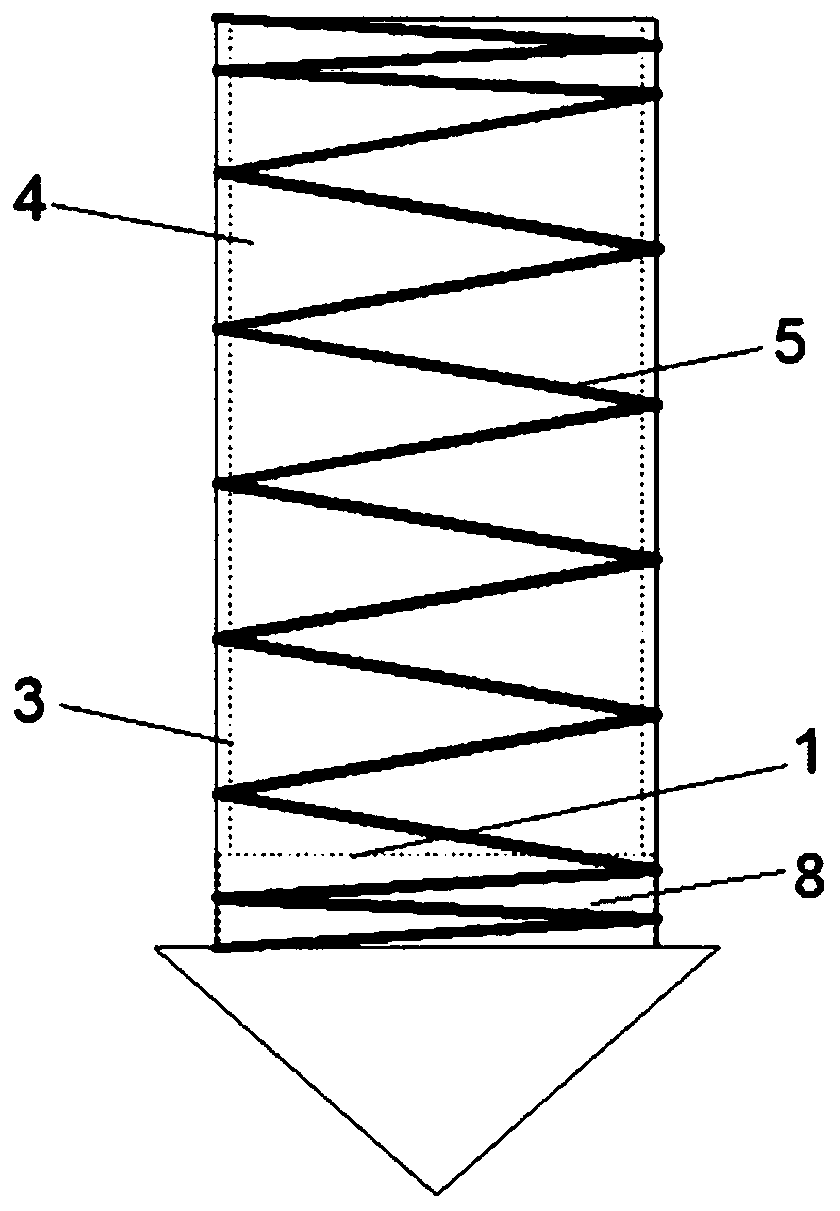

[0042] This embodiment discloses a steel slag permeable concrete pile 7, which is formed by pouring prepared steel slag permeable concrete on site. The steel slag permeable concrete is made up of aggregate, cement, water, and water reducing agent all made of steel slag in a specific mixing ratio. Among them, the amount of cement accounts for 16% of the total raw materials. Studies have shown that the rules applicable to ordinary permeable concrete do not apply to steel slag permeable concrete. Under normal circumstances, the water-cement ratio of permeable concrete is between 0.25 and 0.35. The present invention studies the influence of different water-cement ratios on the compressive strength and water permeability of permeable concrete. A large number of experimental studies have shown that the compressive strength and Permeability coefficients gradually decrease with the increase of water-cement ratio. When the water-cement ratio is 0.25, the performance of steel slag permea...

Embodiment 2

[0048] A steel slag concrete pile is different from Example 1 in that the steel slag concrete pile uses cement, crude steel slag, steel slag powder and water as raw materials to obtain a mixture, wherein, in each cubic meter of the mixture, The weight ratio of cement, steel slag powder, and crude steel slag is 290:80:1200.

Embodiment 3

[0050] A steel slag concrete pile, which is different from Example 1 in that the steel slag concrete pile uses cement, crude steel slag, steel slag powder and water as raw materials to obtain a mixture, wherein, in each cubic meter of the mixture, The weight ratio of cement, steel slag powder and crude steel slag is 280:70:1180.

[0051] After a large number of experimental operations and tests, a series of tests were performed on the steel slag permeable concrete pile 7 and the CFG pile of Examples 1-3. The parameters are shown in Table 1.

[0052]

[0053] Table 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap