Indoor sound insulation wall construction method

A construction method and sound insulation wall technology, which is applied in the direction of walls, floors, coverings/linings, etc., can solve the problems of mold on the wall surface of the indoor sound insulation wall, the impact of the compressive strength of the indoor sound insulation wall, and the impact of the appearance of the wall, etc., to achieve Post-maintenance cost and post-maintenance cost reduction, reduced post-maintenance frequency, and the effect of post-maintenance cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

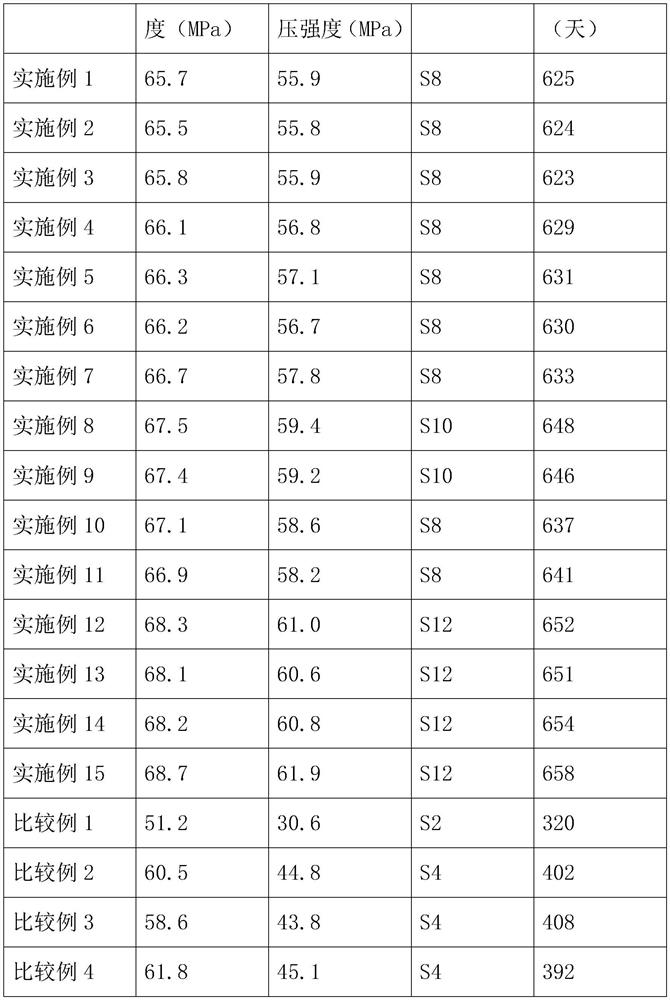

Examples

Embodiment 1

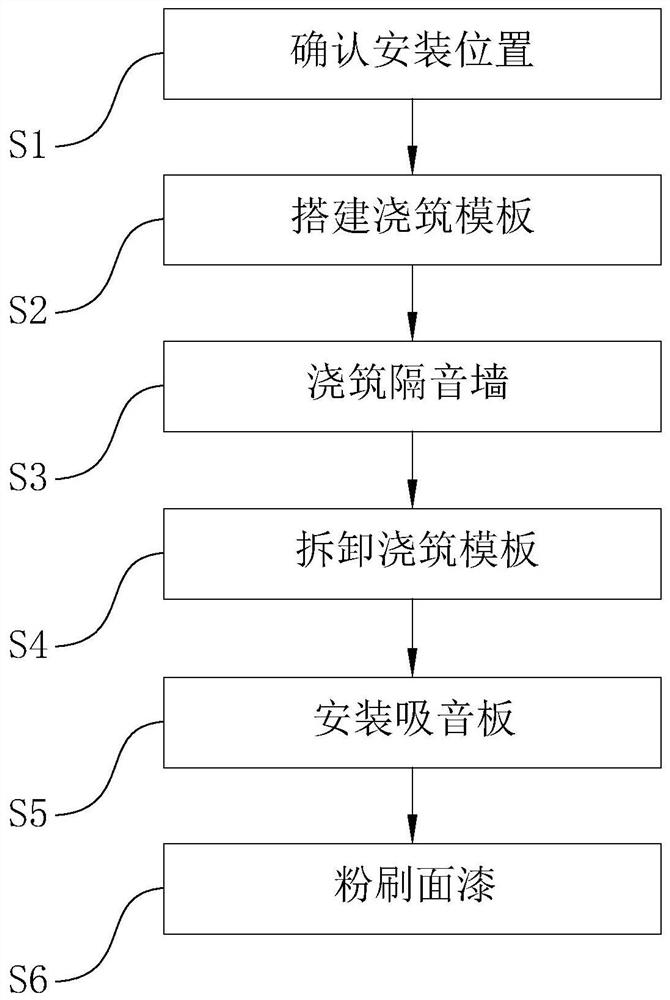

[0067] An indoor partial sound wall construction method, including the following steps:

[0068] S1, confirm the installation location, specifically as follows:

[0069] The size of the construction site is measured according to the design drawings, and the installation position of the indoor soundproof wall is determined, and the horizontal line and the vertical line are marked according to the position and size of the indoor soundproof wall.

[0070] S2, build a pour template, as follows:

[0071] Depending on the marked horizontal line and the position of the vertical line, the pouring template of the indoor soundproof wall is built.

[0072] S3, pouring the sound wall, the specific:

[0073] Pre-prepared concrete, then injecting concrete into the casting template, after the concrete pour is completed, the concrete is covered with the plastic film, and the plastic film is sealed, and the plastic film is always moist. At the same time, the control maintenance temperature is 35 °...

Embodiment 2

[0085] The difference from Example 1 is:

[0086] In step S3, the conservation temperature is 38 ° C, and the control maintenance time is 27 days.

[0087] In step S5, the baking temperature is controlled at 38 ° C.

Embodiment 3

[0089] The difference from Example 1 is:

[0090] In step S3, the conservation temperature is 40 ° C, and the control maintenance time is 25 days.

[0091] In step S5, the baking temperature is controlled at 40 ° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com