The construction method of reinforcing the roadway roof with embedded frp bars

A roadway roof and construction method technology, which is applied to the roof beam supporting the mine roof, earthwork drilling, mining equipment, etc., can solve the problem that the deformation and damage of the roadway roof cannot be effectively controlled, the tensile mechanical properties of steel cannot be fully utilized, and the Effectively play the supporting role and other issues, achieve excellent tensile mechanical properties, avoid poor fire resistance, and ensure effective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

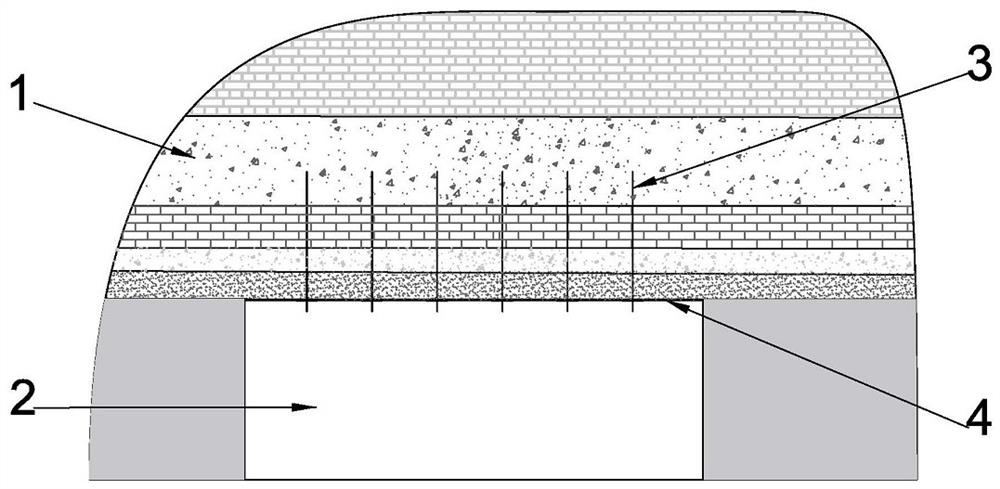

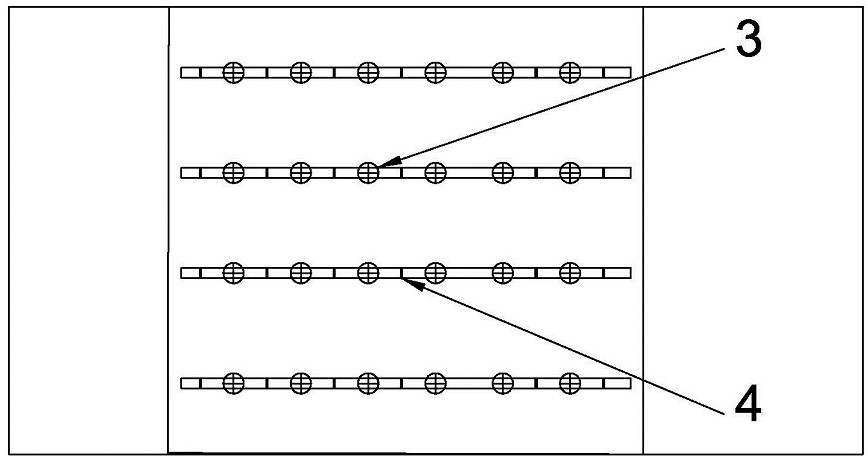

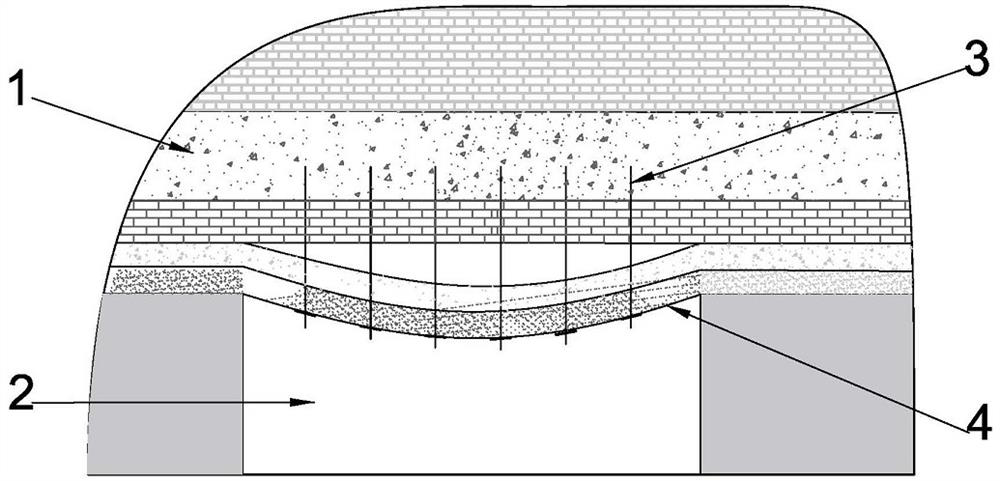

[0042] Embodiments of the construction method of the embedded FRP ribs reinforced roadway roof in the present invention will be further described below with reference to the drawings:

[0043] Such as Figure 1-3 As shown, after the excavation of the roadway 2 is completed, the top plate 1 is reinforced with the anchor 3. In order to further exert the support of the bolt 2 on the roadway 2 top plate 1, the steel barrel 4 is typically provided at a position adjacent the top plate 1 at the tail of the bolt 3. Since the lane 2 is excavated, the original stress state is destroyed, under the influence of the movement, the top plate 1 of the roadway 2 will be sinking, during which the anchor 3 and the steel bar straightener 4 will also appear. Bending sinking.

[0044] Such as Figure 4-5 As shown, the construction method of the embedded FRP ribs reinforced roadway provided by the present invention includes the following steps:

[0045] Step 1, after the roadway is moved, the anchor drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com