A kind of production process of lithium battery cathode composite conductive paste

A technology of composite electrical conductivity and production process, which is applied in the field of production technology of composite conductive slurry for lithium battery positive electrode, can solve the problems such as the slurry is not easy to disperse, and the solid content is low, so as to achieve the advantages of not easy to settle, improve electrical conductivity, and reduce production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

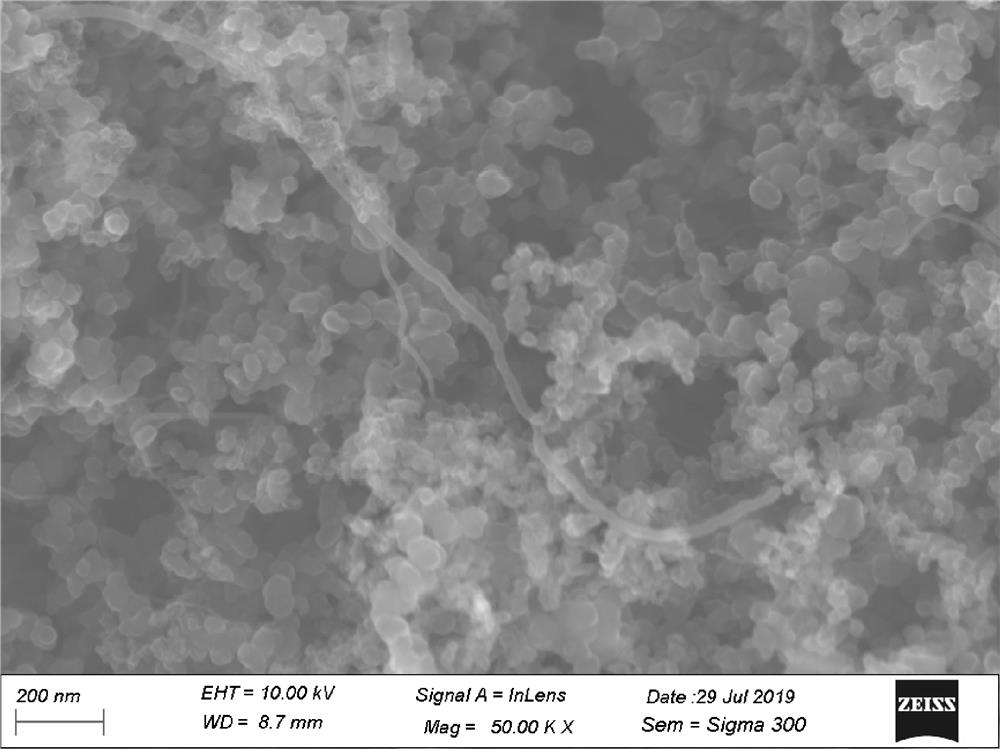

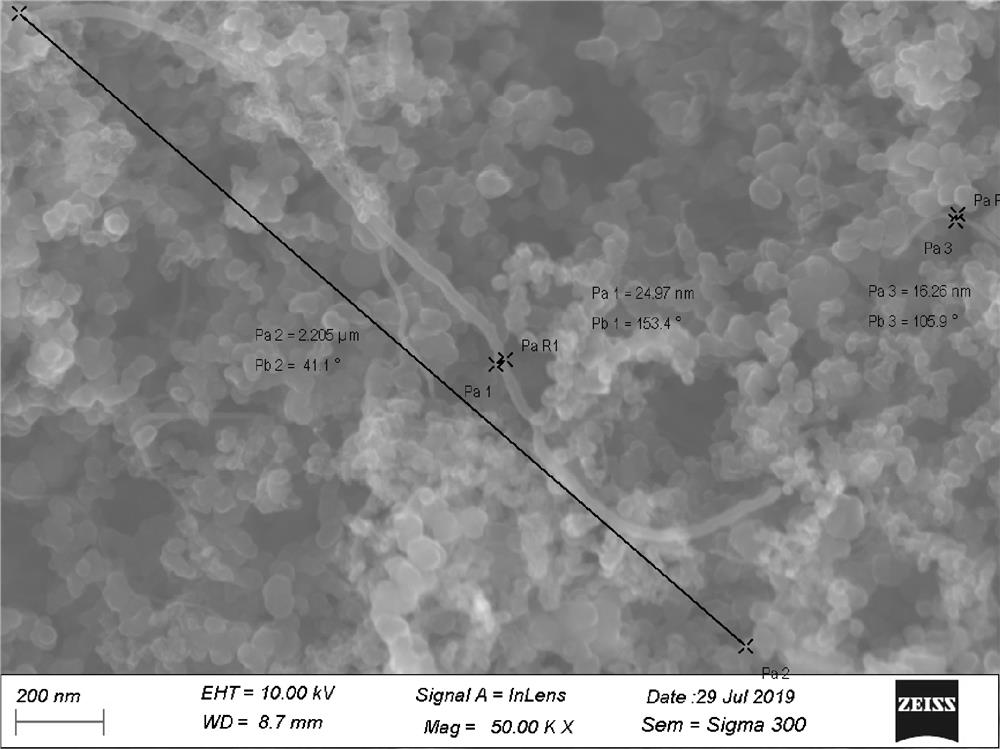

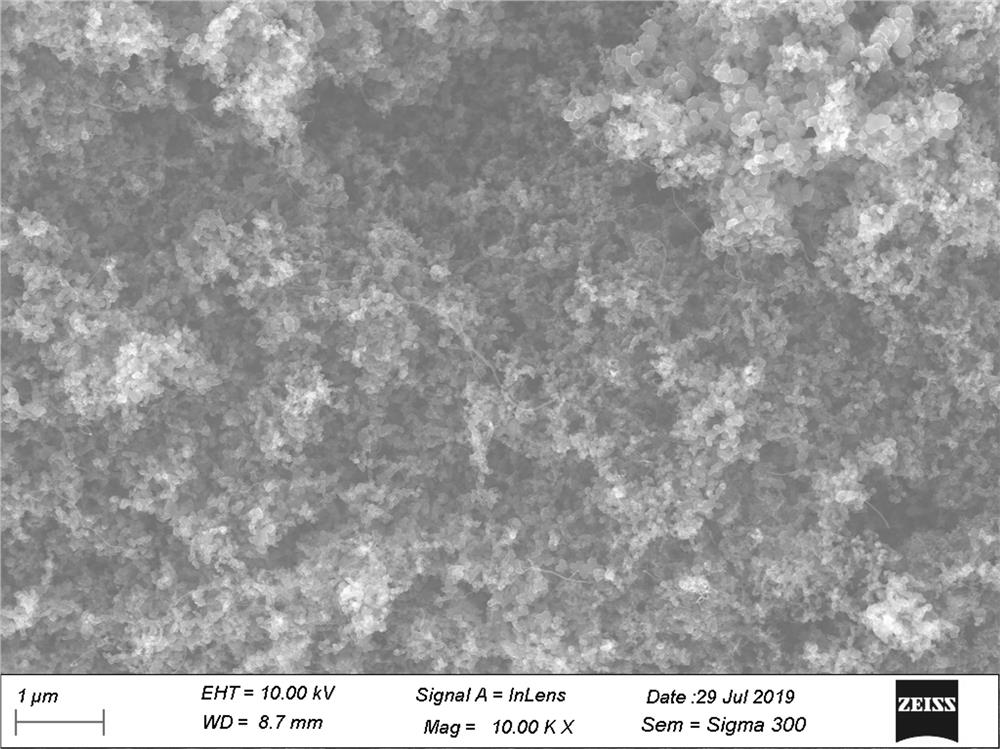

[0041] Embodiment 1: A kind of production technology of lithium battery cathode composite conductive paste, the raw material composition of this composite conductive paste and the percentage of each raw material are conductive carbon black SP content 5.1%-6.1%, CNT content 0.5%-1.1%, The content of Ketjen black is 0.3%-0.6%, the content of NMP is 92.2%-94.1%, and the content of polyvinylpyrrolidone is 0-0.25%. Add the composite conductive paste to the high-speed disperser respectively. The high-speed disperser adopts four-stage stirring speed , the four-stage stirring rate includes a first-stage initial stirring rate of 500-1000r / min, a second-stage initial stirring rate of 1500-2000r / min, a third-stage fine stirring rate of 2500-4000r / min and a fourth-stage fine stirring rate of 4500-5000r / min min, the total stirring time of the four-stage stirring is 90-120min.

[0042] The raw material composition of this composite conductive paste and the percentage of each raw material ar...

Embodiment 2

[0051] Embodiment 2: A production process of lithium battery positive electrode composite conductive paste, the raw material composition of the composite conductive paste and the percentage of each raw material are conductive carbon black SP content 5.5%, CNT content 0.75%, Ketjen Black content 0.6% , NMP content 92.9% and polyvinylpyrrolidone content 0.25%, adopt the following processing steps:

[0052] 1) Step 1: Mix CNT and Ketjen Black to make auxiliary materials for later use.

[0053] 2) Step 2: Add 55%-60% of the volume of NMP, 20%-30% of the volume of the auxiliary materials and all polyvinylpyrrolidone into the high-speed disperser for primary primary stirring, the high-speed disperser The stirring head extends to one-third of the liquid surface for stirring, the rotating speed is 500-1000r / min, and the continuous stirring time is 10-15min, preferably 60% of the volume of NMP and 30% of the volume of the auxiliary material, Pre-adding 30% of auxiliary materials is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com