Polymer coating diaphragm used for lithium ion battery

A polymer coating and lithium-ion battery technology, which is applied to battery pack components, separators/films/diaphragms/spacers, circuits, etc., can solve the problems of weak battery hardness, poor viscosity, and large resistance increase , to achieve the effect of reducing the increase of the air permeability value, increasing the conductivity, and reducing the increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this example, anilox roller coating is used to prepare the polymer-coated separator for lithium-ion batteries of the present invention.

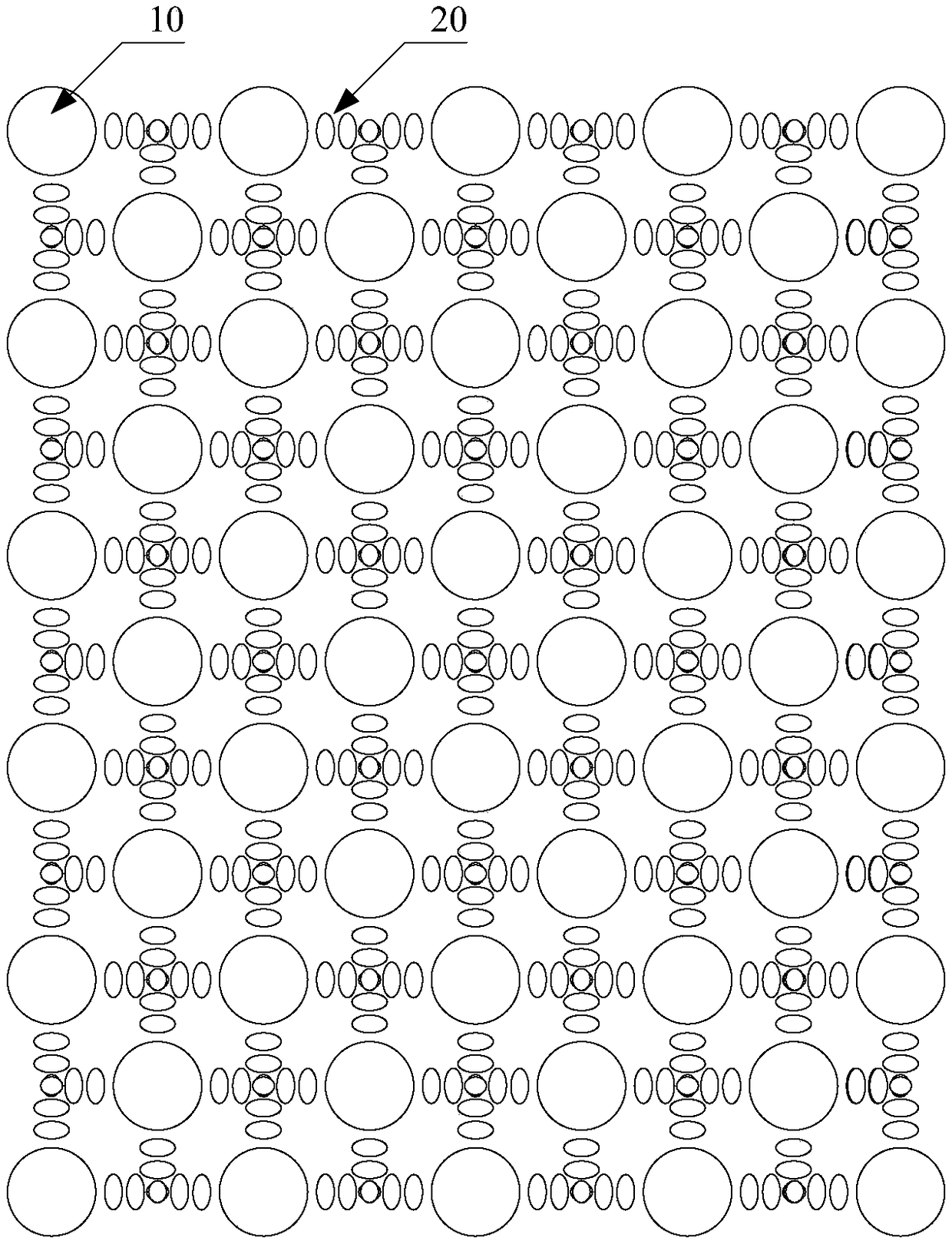

[0045] The preparation of consistent polymer slurry is achieved by a dot-shaped anilox roller designed with regular size engraving points, where the surface of the anilox roller is set with notches of large and small pits at specific positions, and the interval between the notches is 100- 800 microns, pattern as figure 1 As shown, using the printing principle, the polymer paste is coated on the base film.

[0046] Such as figure 1 As shown in the schematic diagram, using the pattern of the anilox roller, under the action of coating pressure, the polymer is distributed in the way of concave points 10 and small points 20 on the anilox roller, and finally the diaphragm base film is distributed into corresponding The structure of a polymer with bumps and dots at intervals.

[0047] Preparation of water-based polymer slurry: Mix and ...

Embodiment 2

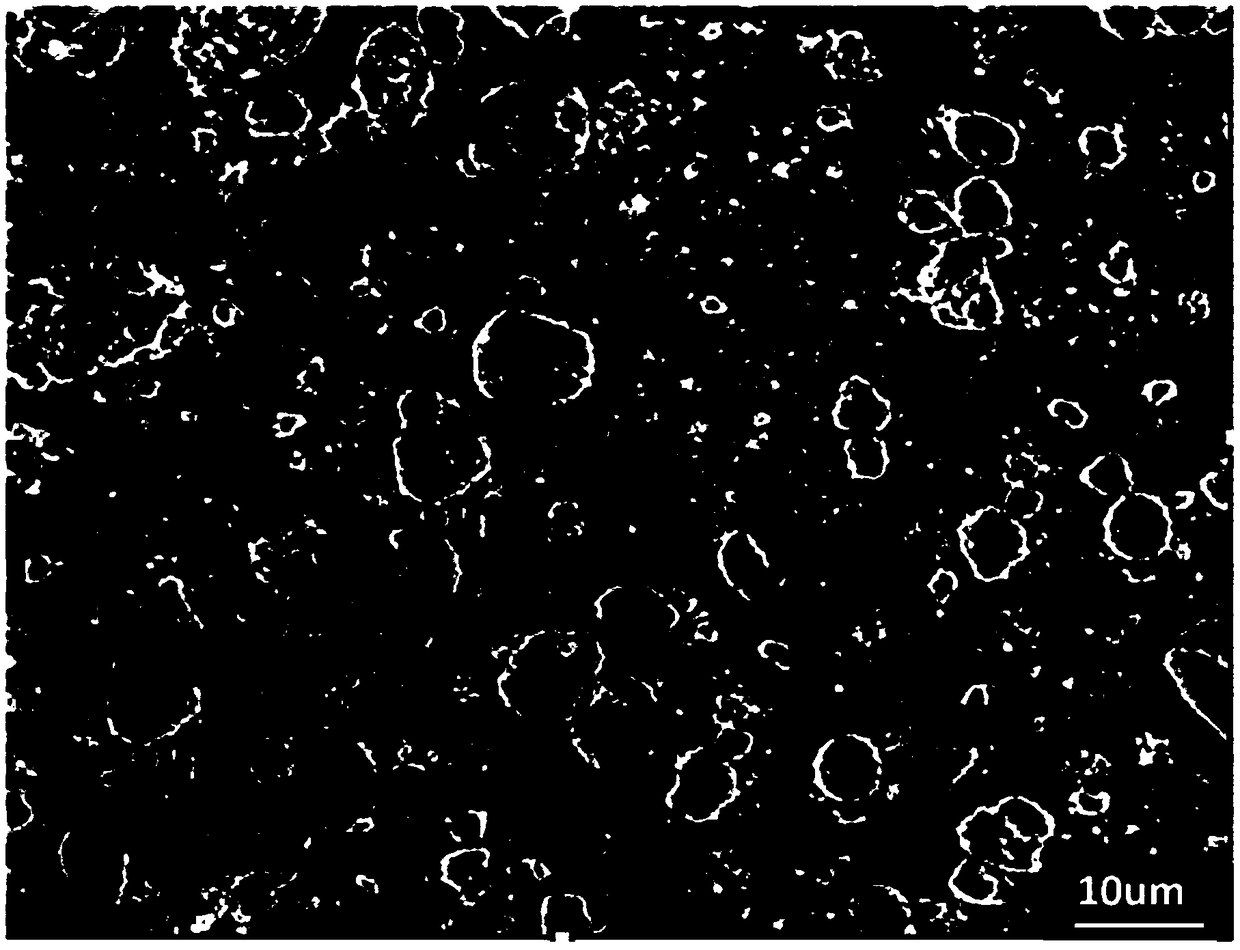

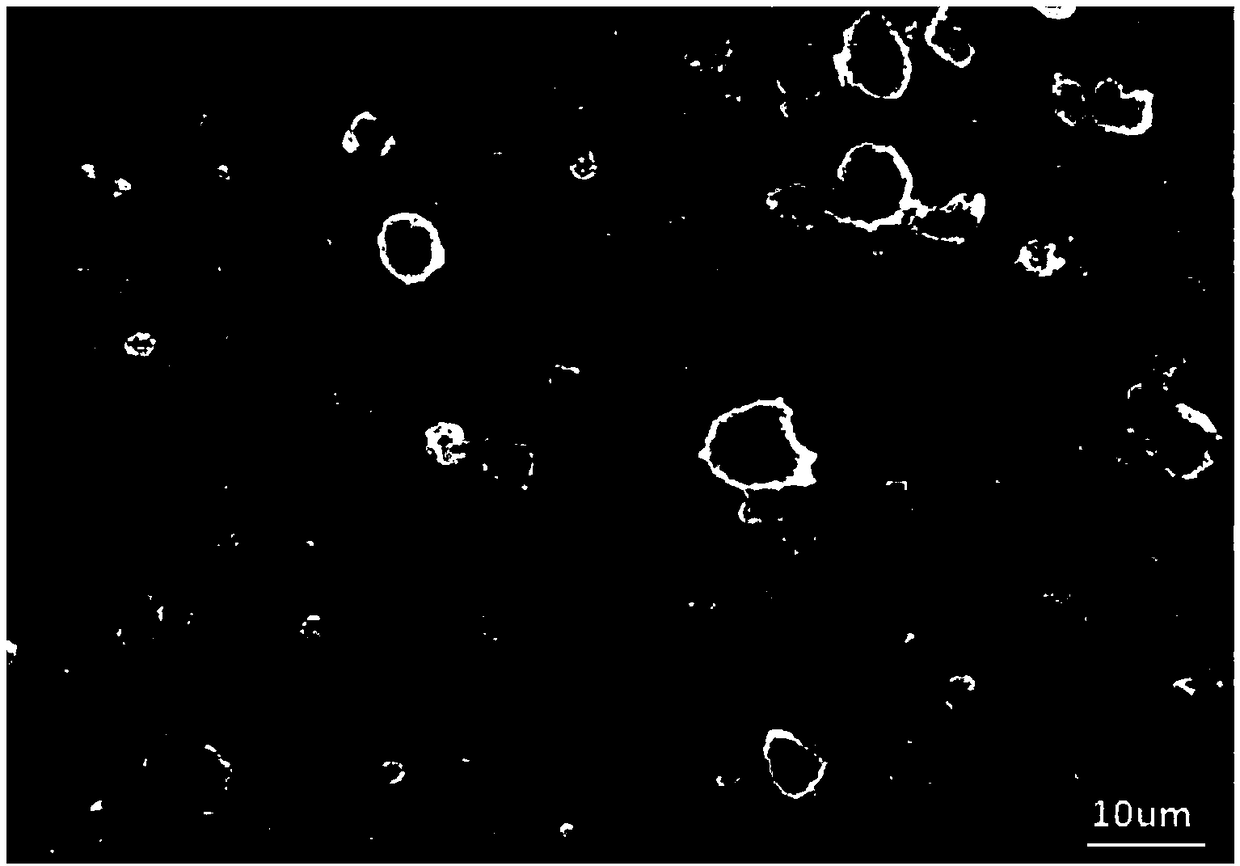

[0055] In this embodiment, the slurry with non-uniform size and particle size is used to prepare the polymer-coated separator for lithium-ion batteries of the present invention.

[0056] Polymers with double peaks in particle size distribution are used, and the peak distributions are located at 5-10 microns and 0.1-1 microns respectively. The slurry is prepared, transferred to the substrate by micro-gravure coating, and distributed on both sides of the film.

[0057] Preparation of water-based polymer slurry: Mix and stir 78 parts of deionized water and 12 parts of polyvinylidene fluoride evenly, then add 10 parts of CMC and mix and stir evenly to obtain a stable and uniform water-based mixed slurry; the particle size distribution of the obtained slurry is The range is controlled at D50<20um.

[0058] Coating: The aqueous mixed slurry prepared in step 1 is coated on both sides of a PP film with a thickness of 20um by micro-gravure coating to form a polymer coating, which is dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com