Structure for reducing shaft voltage of PWM inverter driving type plastic package motor

A plastic-encapsulated motor and drive-type technology, which is applied in the direction of motor-generator connectors, structural connections, circuits, etc., can solve problems such as the influence of motor application range, complex insulation structure, and the plastic insulation layer cannot withstand large torques, etc., to avoid electric shocks. Corrosion risk, improved life and reliability, effect of reduced shaft voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

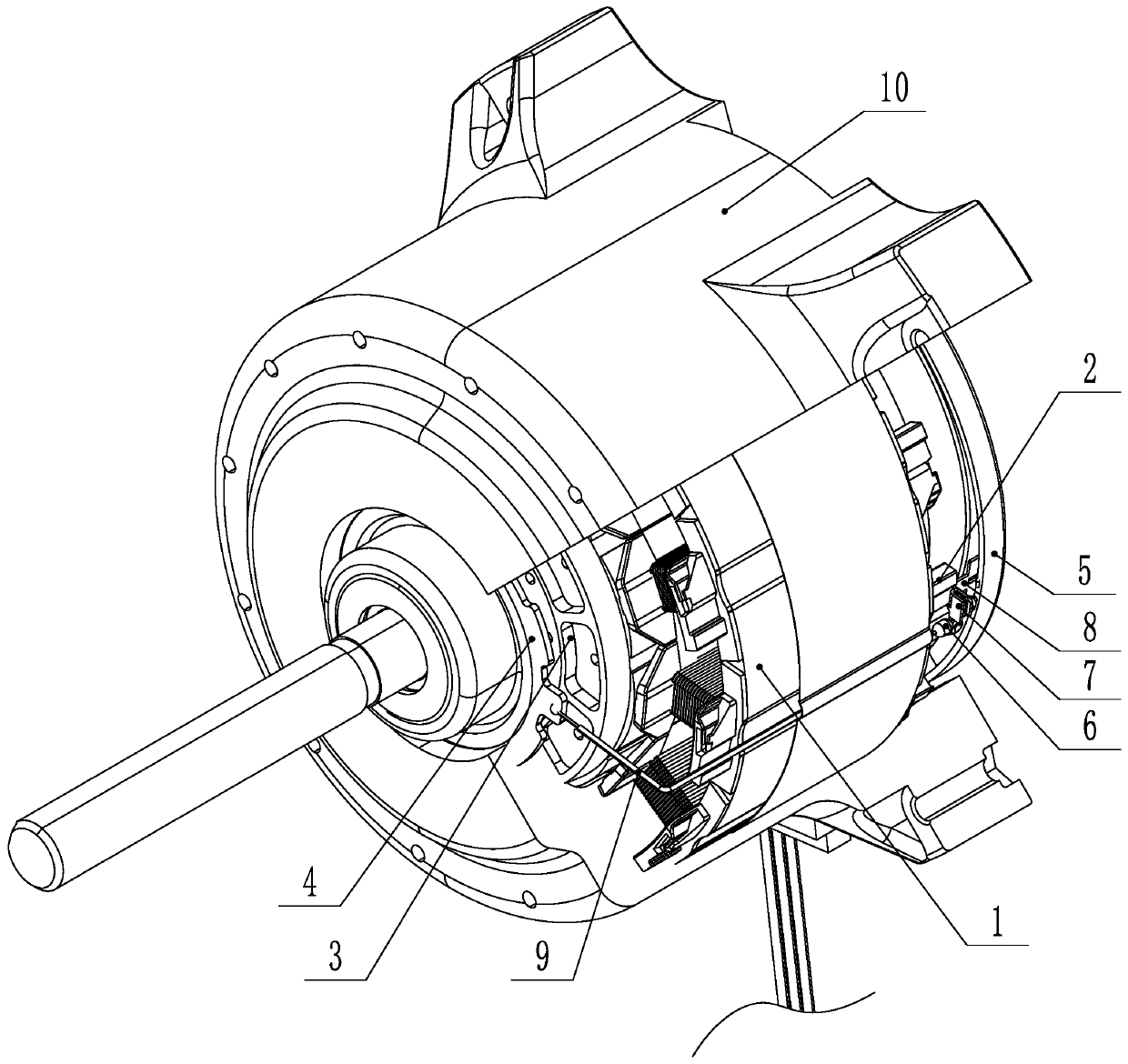

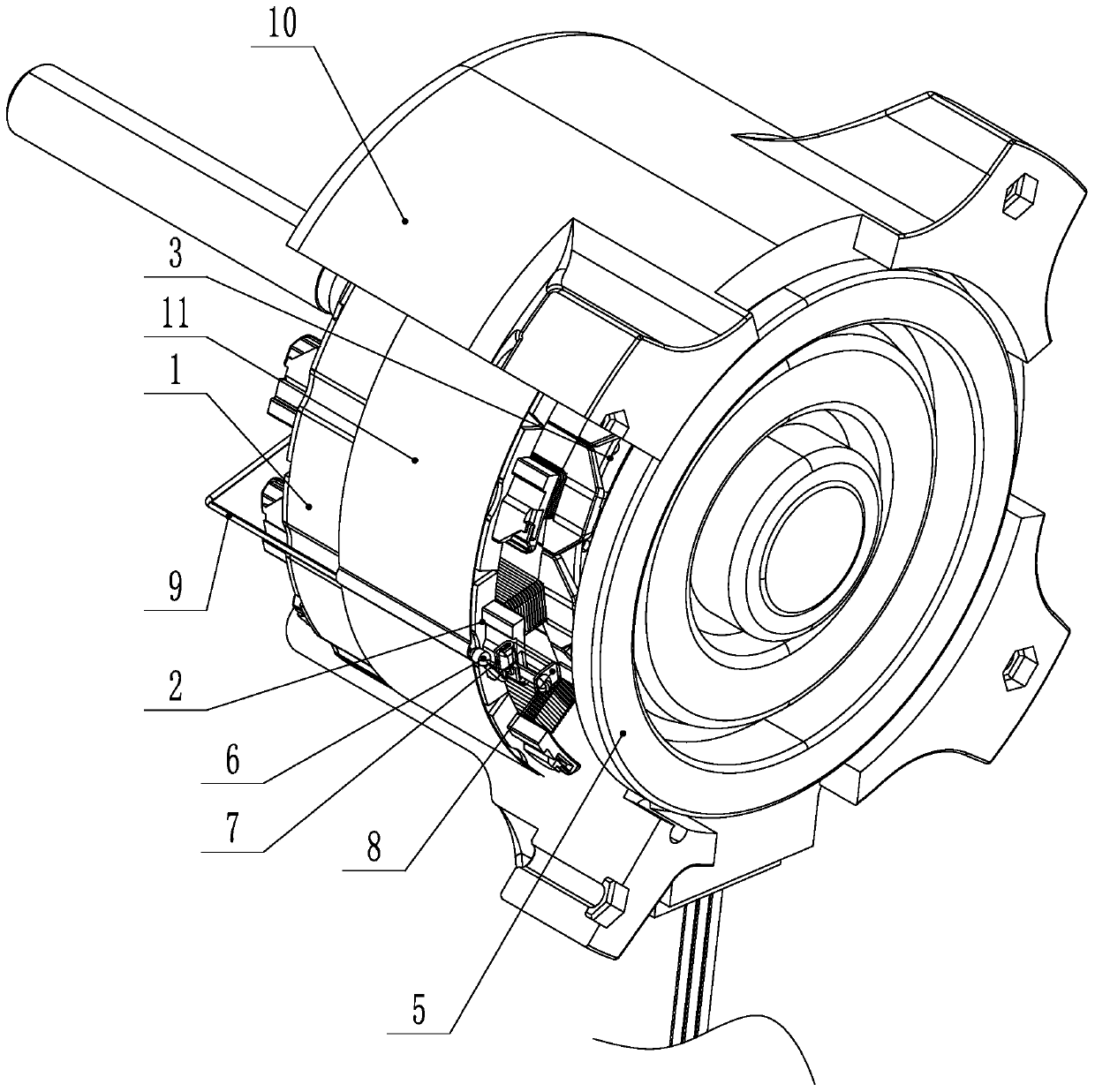

[0022] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

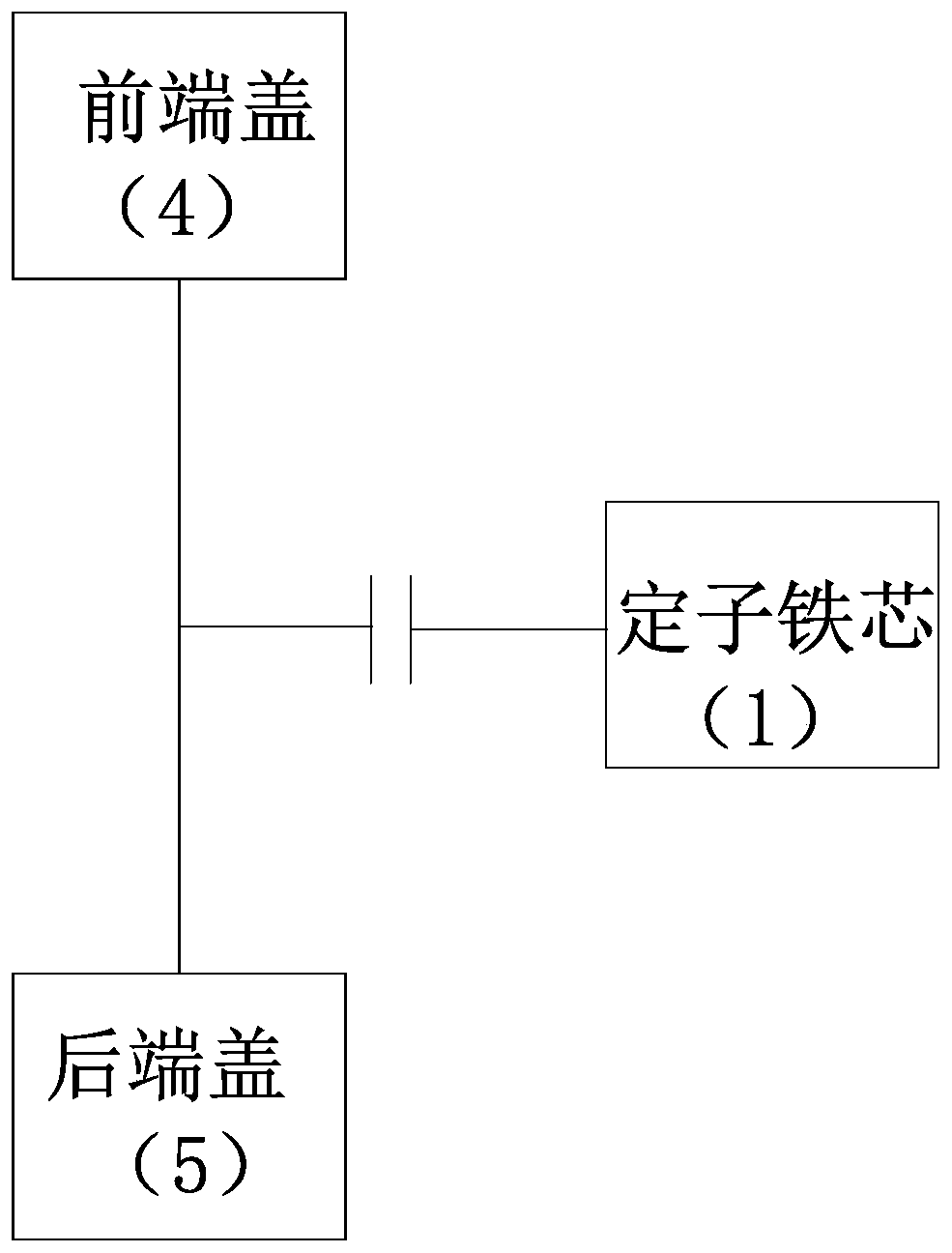

[0023] Such as Figure 1-5 As shown, a structure for reducing the shaft voltage of a PWM inverter-driven plastic-enclosed motor. The PWM inverter-driven plastic-enclosed motor includes a winding stator core 1), a stator core insulating skeleton 2, a rotor 3, a front cover 4 and The rear end cover 5, the front end cover 4 and the bearing chamber of the rear end cover 5 are provided with bearings, and there are windings. The stator core 1, the insulating frame 2 and the front end cover 4 are plastic-sealed together by a plastic seal 10. The front end cover 4 and the rear end cover 5 They are connected through conductive parts to achieve equipotentiality, and a capacitor 6 is connected between the conductive parts and the stator core 1 .

[0024] In order to realize the electrical connection between the front end cover 4 and the rear e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com