Power generation structure and energy collection device

A power generation unit and electrode technology, applied in the direction of friction generators, etc., can solve the problems of TENG output peak ratio, power loss, output peak ratio, etc., to achieve the effect of optimizing circuit connection mode, reducing energy loss, and reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0079] In a first exemplary embodiment of the present disclosure, a power generating structure is provided, which is a rotary structure.

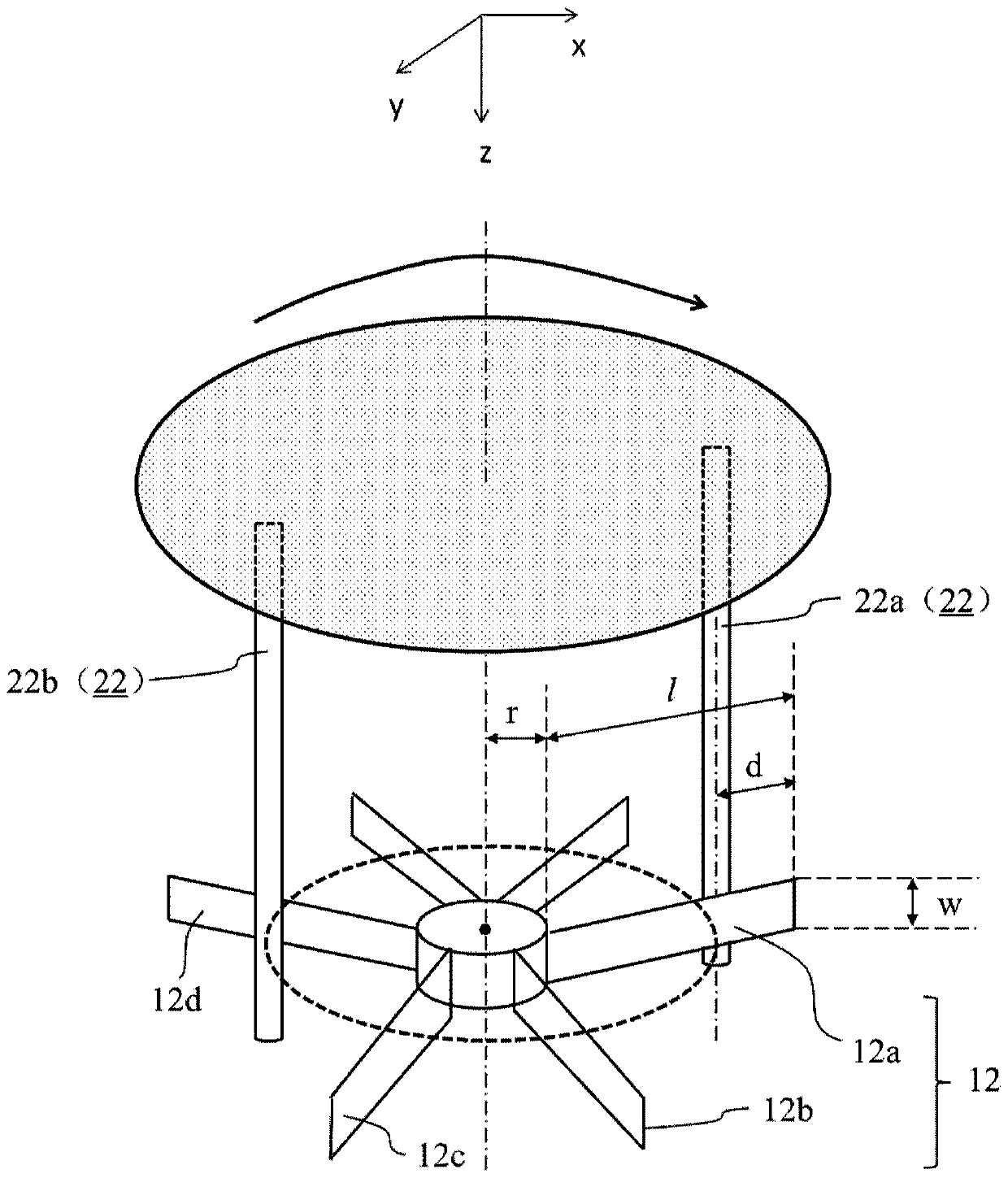

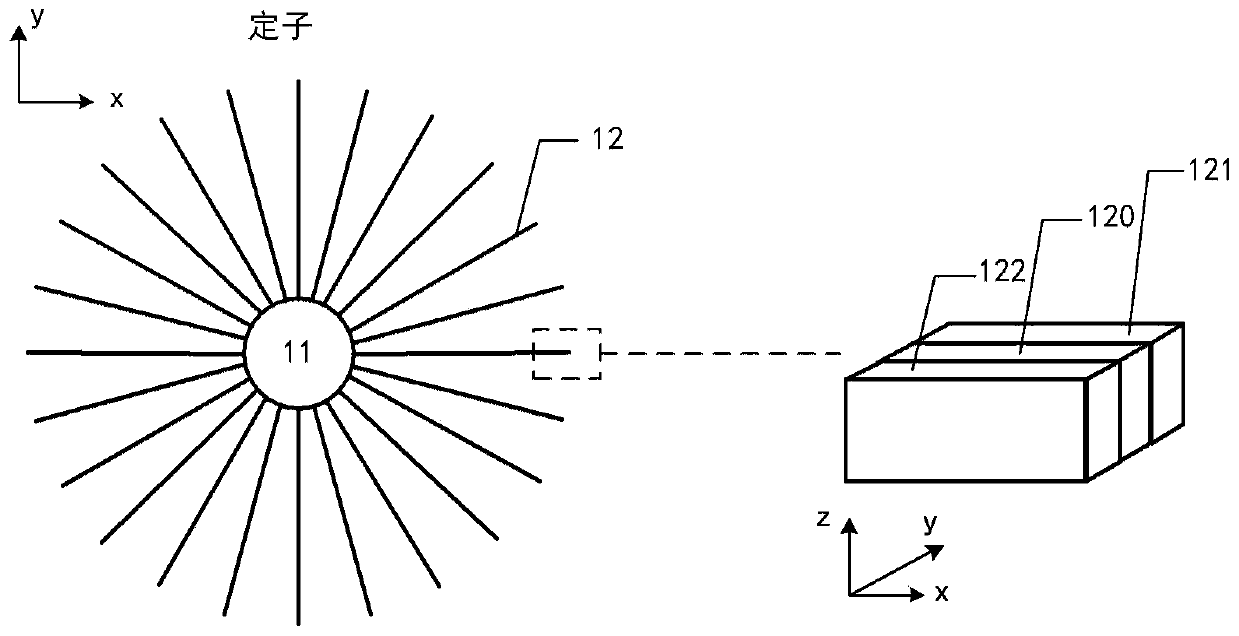

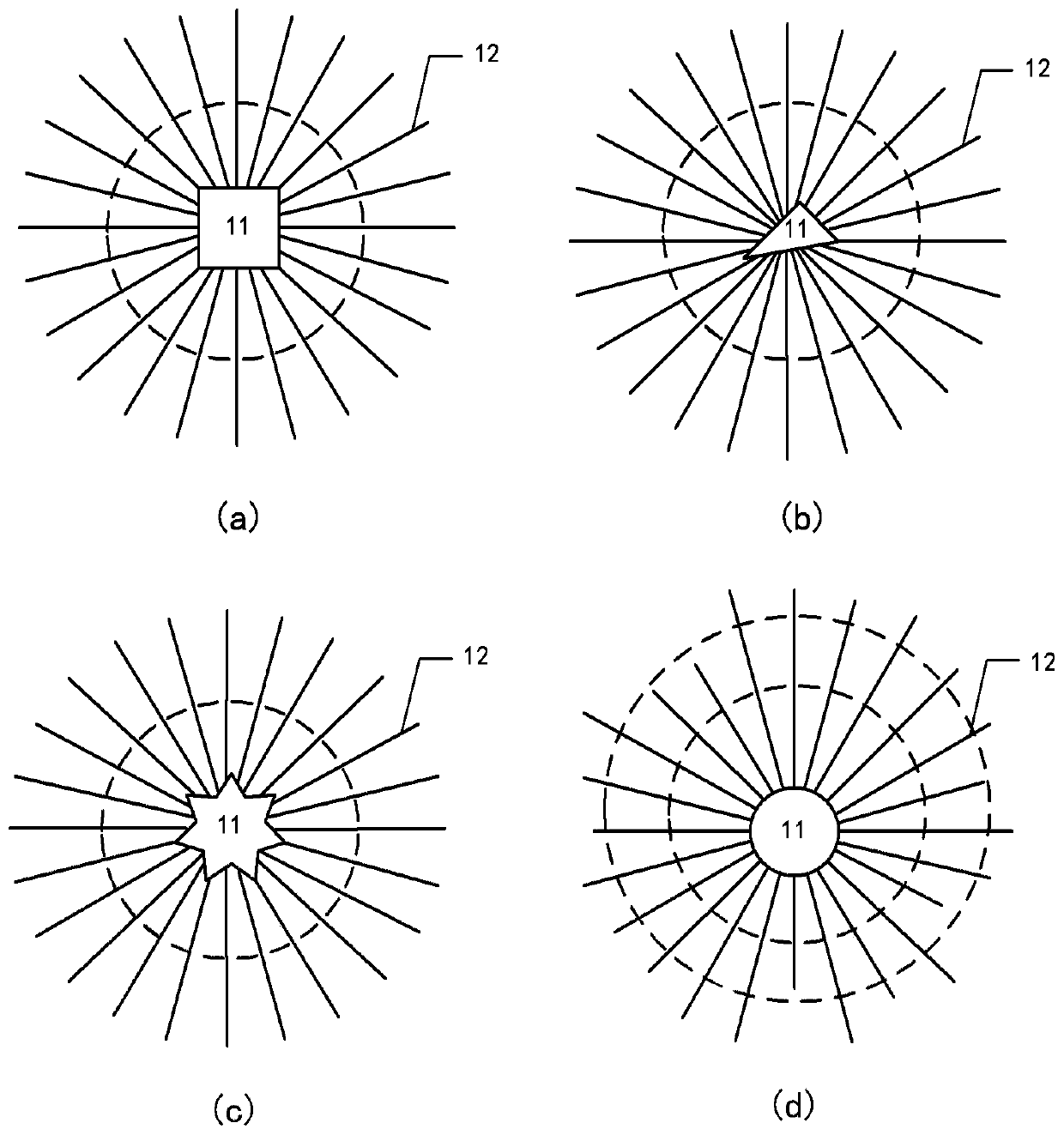

[0080] figure 1 It is a schematic diagram showing that the power generating structure is a rotating structure according to an embodiment of the present disclosure. figure 2 For such figure 1 The structure schematic diagram of the electrode unit group in the rotary structure shown as a stator, wherein the dotted line box shows a three-dimensional perspective view of one of the electrode units. Figure 4 For such figure 1 The schematic diagram of the structure in which the push rod in the rotary structure is shown as the rotor.

[0081] refer to figure 1 , figure 2 with Figure 4 As shown, the power generation structure of the present disclosure includes: an electrode unit group, including a plurality of electrode units 12 arranged at intervals, and the materials on the opposite surfaces of adjacent electrode units 12 are located in d...

no. 2 example

[0109] In the second exemplary embodiment of the present disclosure, a power generation structure is provided. On the basis of the structure of the first embodiment, the power generation structure of this embodiment optimizes the circuit connection mode and realizes low peak ratio and reduce power loss.

[0110] Image 6 It is a schematic diagram of a power generation structure including a plurality of uniformly distributed electrode units according to an embodiment of the present disclosure. Figure 7 with Figure 8 The comparison shows that Image 6 The power generation structure shown is a schematic diagram of using different circuit connection methods for electrical output. Figure 7 For such Image 6 In the power generation structure shown, each pair of electrode units is connected in parallel and rectified by a common rectifier bridge (single rectifier bridge). Figure 8 For such Image 6 In the power generation structure shown, each pair of electrode units is rect...

example 1

[0119] By adjusting the width of the electrode sheet, a higher equivalent current output can be obtained.

[0120] Figure 12 It is the output variation curve caused by different electrode width w in the power generation structure shown according to an example of the present disclosure. Here the radius of the support ring (first support) of the stator is 4cm, the number of electrode sheets (electrode units) is 24, the length of the electrode sheet is 10cm, the number of push rods is 4, and the push rod reaches the end of the electrode sheet The vertical distance is 2cm, and the width (w) of the electrode sheet ranges from 2cm to 5cm. Such as Figure 12 As shown, the peak ratio obtained in the test is between 1-2, and the equivalent current increases with the increase of the electrode width. At the same time, with the increase of the rotational speed, the equivalent current also gradually increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com