A kind of mildew-proof polyester with high washing resistance and preparation method thereof

A technology with high washing resistance and mildew resistance, applied in the field of fabrics, it can solve the problems of mildew rot of textiles, generation of bacterial plaque, affecting the finishing effect and the quality of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 3-Chloro-2-hydroxypropyl methacrylate: CAS number: 13159-52-9; source: Shanghai Xianding Biotechnology Co., Ltd.;

[0033] N-methyliminodiacetic acid: CAS number: 4408-64-4; source: Shanghai Xianding Biotechnology Co., Ltd.

[0034] The preparation method of modifying agent is:

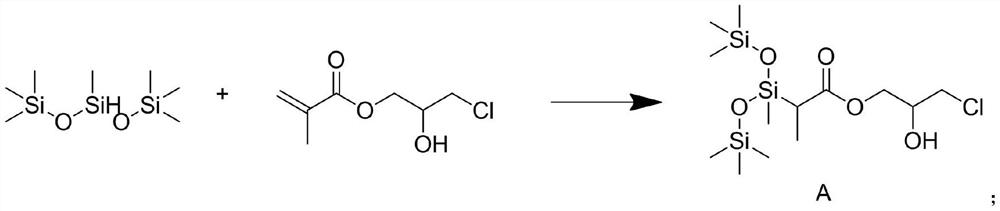

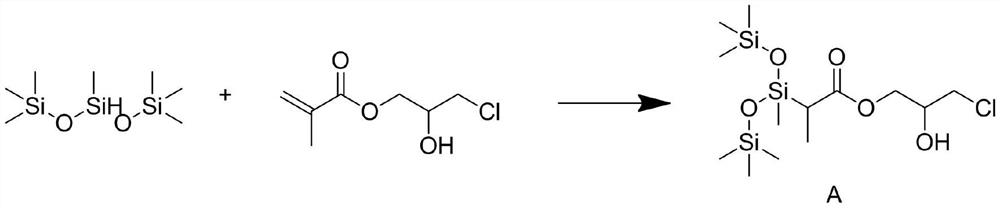

[0035] S1. Add 1 mol of heptamethyltrisiloxane and 1.12 mol of 3-chloro-2-hydroxypropyl methacrylate into the reaction kettle, add 1.5L of solvent isopropanol, and blow nitrogen gas at a rate of 1°C / min Raise the temperature to 90°C, add 10 mg of chloroplatinic acid dropwise, and keep the reaction for 5 hours. After the reaction, the solvent and low boilers were distilled off under reduced pressure, and cooled to room temperature to obtain Compound A with a yield of 96.7%. The reaction formula is as follows:

[0036]

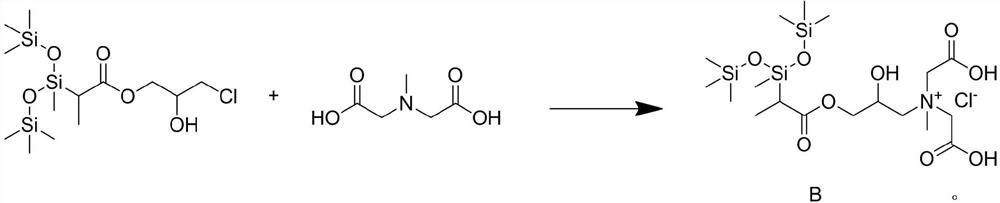

[0037] S2. First, add 1.02mol N-methyliminodiacetic acid into the miniature reactor, add 2L solvent acetonitrile, stir to make it dissolve completely, add the compound A prep...

Embodiment 2

[0041]A mildew-resistant polyester with high washability, starting from terephthalic acid and ethylene glycol, after the esterification reaction of terephthalic acid and ethylene glycol, adding a modifier to participate in the polymerization reaction, Embedding modifiers to obtain modified anti-mildew polyester;

[0042] The preparation method of the mildew-resistant polyester with high washability specifically comprises the following steps:

[0043] The first step, esterification

[0044] Add 1mol of terephthalic acid and 1.2mol of ethylene glycol into the polymerization reactor, add 15g of esterification catalyst tetrabutyl titanate, turn on the heating, when the temperature reaches 180°C, turn on the stirring, at a speed of 70rpm / min Under stirring, carry out esterification reaction 50min;

[0045] The second step, aggregation

[0046] After the esterification reaction, continue to heat up to 250 ° C, add 0.22 mol modifier and 0.4 mol polyethylene glycol, then add 8 g of...

Embodiment 3

[0048] A mildew-resistant polyester with high washability, starting from terephthalic acid and ethylene glycol, after the esterification reaction of terephthalic acid and ethylene glycol, adding a modifier to participate in the polymerization reaction, Embedding modifiers to obtain modified anti-mildew polyester;

[0049] The preparation method of the mildew-resistant polyester with high washability specifically comprises the following steps:

[0050] The first step, esterification

[0051] Add 1mol of terephthalic acid and 1.4mol of ethylene glycol into the polymerization reactor, add 16g of esterification catalyst tetrabutyl titanate, turn on the heating, when the temperature reaches 190°C, turn on the stirring, at a speed of 60rpm / min Under stirring, carry out esterification reaction 40min;

[0052] The second step, aggregation

[0053] After the esterification reaction, continue to heat up to 255 ° C, add 0.25 mol modifier and 0.3 mol polyethylene glycol, then add 10 g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com