Sr-Zr-Ti ternary composite microalloyed Al-Si-Cu line cast aluminium alloy and preparation method

A technology for casting aluminum alloy and al-si-cu is applied in the field of aluminum alloy materials and their preparation to achieve the effects of improving strength, hardness, elongation and hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

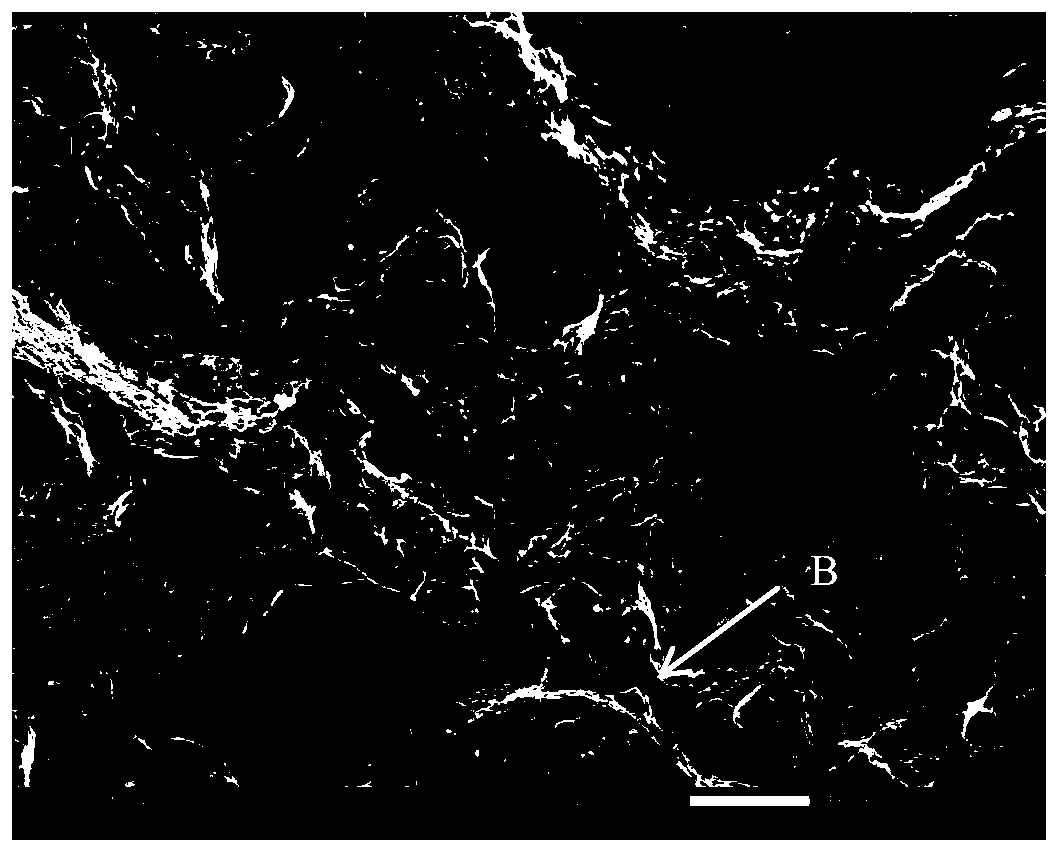

[0029] Such as figure 1 , 2 shown.

[0030] A Sr, Zr, Ti ternary composite micro-alloyed high-strength and high-hardness Al-Si-Cu cast aluminum alloy, which is prepared by the following method:

[0031] First, put pure Al, Al-Si master alloy and Al-Cu master alloy in a resistance wire melting furnace and heat up to 850±10°C, then add Al-Sr master alloy, Al-Zr master alloy and Al- Ti-B master alloy. Next, keep warm for 1.5~2h. After all the intermediate alloys and metals are melted, adjust the temperature to 760±10°C, add hexachloroethane once to degas until no gas escapes, let it stand for 15 minutes, and then add hexachloroethane The alkane is degassed twice until no gas escapes, and after standing for 15 minutes, the slag is removed and poured into a metal mold preheated to 400±10°C to cast an ingot. Finally, 250±10℃×6h+350±10℃×6h+450±10℃×6h+480±10℃×6h for homogenization annealing, 480±10℃×1h+490±10℃×1h for solid solution , Quenching in warm water at 60±5°C, aging treat...

Embodiment 2

[0035] A Sr, Zr, Ti ternary composite micro-alloyed high-strength and high-hardness Al-Si-Cu cast aluminum alloy, which is prepared by the following steps:

[0036] First, put pure Al, Al-Si master alloy and Al-Cu master alloy in a resistance wire melting furnace and heat up to 850±10°C, then add Al-Sr master alloy, Al-Zr master alloy and Al- Ti-B master alloy. Next, keep warm for 1.5~2h. After all the intermediate alloys and metals are melted, adjust the temperature to 760±10°C, add hexachloroethane once to degas until no gas escapes, let it stand for 15 minutes, and then add hexachloroethane The alkane is degassed twice until no gas escapes, and after standing for 15 minutes, the slag is removed and poured into a metal mold preheated to 400±10°C to cast an ingot. Finally, 250±10℃×6h+350±10℃×6h+450±10℃×6h+480±10℃×6h for homogenization annealing, 480±10℃×1h+490±10℃×1h for solid solution Treatment, quenching in warm water at 60±5°C, aging treatment at 191±10°C×12h, and coolin...

Embodiment 3

[0040] The preparation method of the third example is the same as that of the first and second examples, except that the high-strength and high-hardness Al-Si-Cu cast aluminum alloy of this example is subjected to EDS The actual measured composition is: 8.57%Si, 5.32%Cu, 0.55%Sr, 0.62%Zr, 0.19%Ti, and the balance is aluminum and impurity elements. The high-strength and high-hardness Al-Si-Cu cast aluminum alloy of the present example is composed of Sr, Zr, and Ti ternary composite micro-alloys. The structure is dense, the Si phase is fine, and the shape is granular or short. The fracture rate is 4.8%. The fracture is a typical ductile fracture with dimple characteristics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com