Novel heat-resistant, high-strength, high-plasticity and corrosion-resistant Al-Cu-Mg-Zn-Ti aluminum alloy and preparation method thereof

An al-cu-mg-zn-ti, high plasticity technology, applied in the field of aluminum alloy materials, can solve the problems of heat resistance, high strength, high plasticity and corrosion resistance, so as to improve the heat treatment process, improve plasticity and toughness , Strengthen the effect of aluminum alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

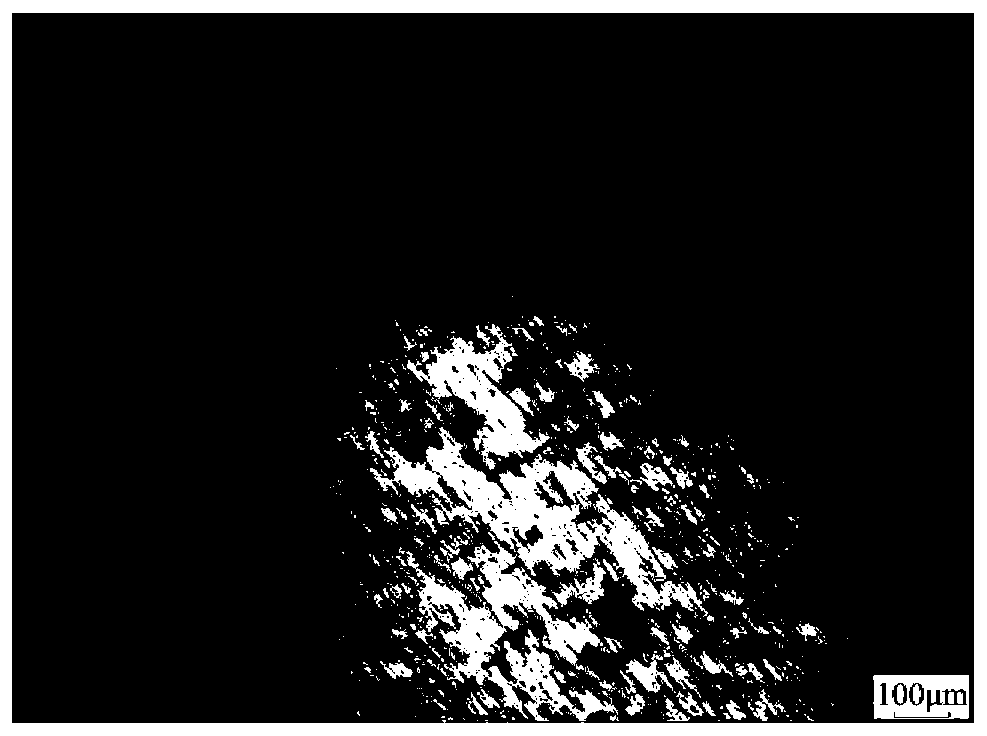

[0028] Such as figure 1 shown.

[0029] A novel heat-resistant and corrosion-resistant high-strength and high-plasticity Al-Cu-Mg-Zn-Ti aluminum alloy, which is prepared by the following steps:

[0030] First, A00 grade pure Al (ingredients: 99.79%Al, 0.14%Fe, 0.04%Si, all the components in the present invention are represented by mass percentage, the same below, and the part where the sum of the components is less than 100% is the impurity) is melted Then add Al-Cu master alloy (49.62%Al, 50.12%Cu, 0.15%Fe, 0.11%Si), Al-Ti-B master alloy (5.11%Ti), Al-Zr master alloy (95.69%Al, 4.11% %Zr, 0.20%Fe, 0.10%Si ), Al-Sr master alloy (90%Al, 9.89%Sr, 011%Si). Then add pure Zn (the loss rate of Zn is about 8%) and pure Mg (the loss rate of Mg is about 8%). The master alloy can be purchased directly from the market, or can be prepared by yourself by conventional methods. During the melting process, the former master alloy or metal is melted, and then the latter master alloy or meta...

Embodiment 2

[0034] Such as figure 2 shown.

[0035]A novel heat-resistant, high-strength, high-plasticity, corrosion-resistant Al-Cu-Mg-Zn-Ti aluminum alloy is prepared by the following steps:

[0036] First, A00 grade pure Al (ingredients: 99.79%Al, 0.14%Fe, 0.04%Si, all the components in the present invention are represented by mass percentage, the same below, and the part where the sum of the components is less than 100% is the impurity) is melted Then add Al-Cu master alloy (49.62%Al, 50.12%Cu, 0.15%Fe, 0.11%Si ), Al-Zr master alloy (95.69%Al, 4.11%Zr, 0.20%Fe, 0.10%Si ), Al -Sr master alloy (90%Al, 9.89%Sr, 011%Si). Add pure Zn again (the loss rate of Zn is about 8%), pure Mg (the loss rate of Mg is about 8%), and described master alloy can be purchased directly from the market, also can adopt conventional method self-preparation, melting process After the former master alloy or metal is melted, add the latter master alloy or metal, after all are melted into the aluminum solution...

Embodiment 3

[0040] The preparation method and effect of this embodiment are the same as or similar to those of Embodiments 1 and 2, except that the actual composition of the aluminum alloy of this embodiment measured by EDS is: 2.88%Cu, 3.84%Mg, 2.89%Zn, 0.11% Sr, 0.19% Zr, 0.6% Ti, the balance is aluminum and impurity elements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum corrosion depth | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Maximum corrosion depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com