Cable-stayed bridge

A cable-stayed bridge and bridge body technology, which is applied to suspension bridges, bridges, bridge forms, etc., can solve the problems of inconvenient maintenance and repair, low load capacity of steel cable bridges, and unsuitable for vehicle traffic. The effect of stable bridge deck structure and reduction of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

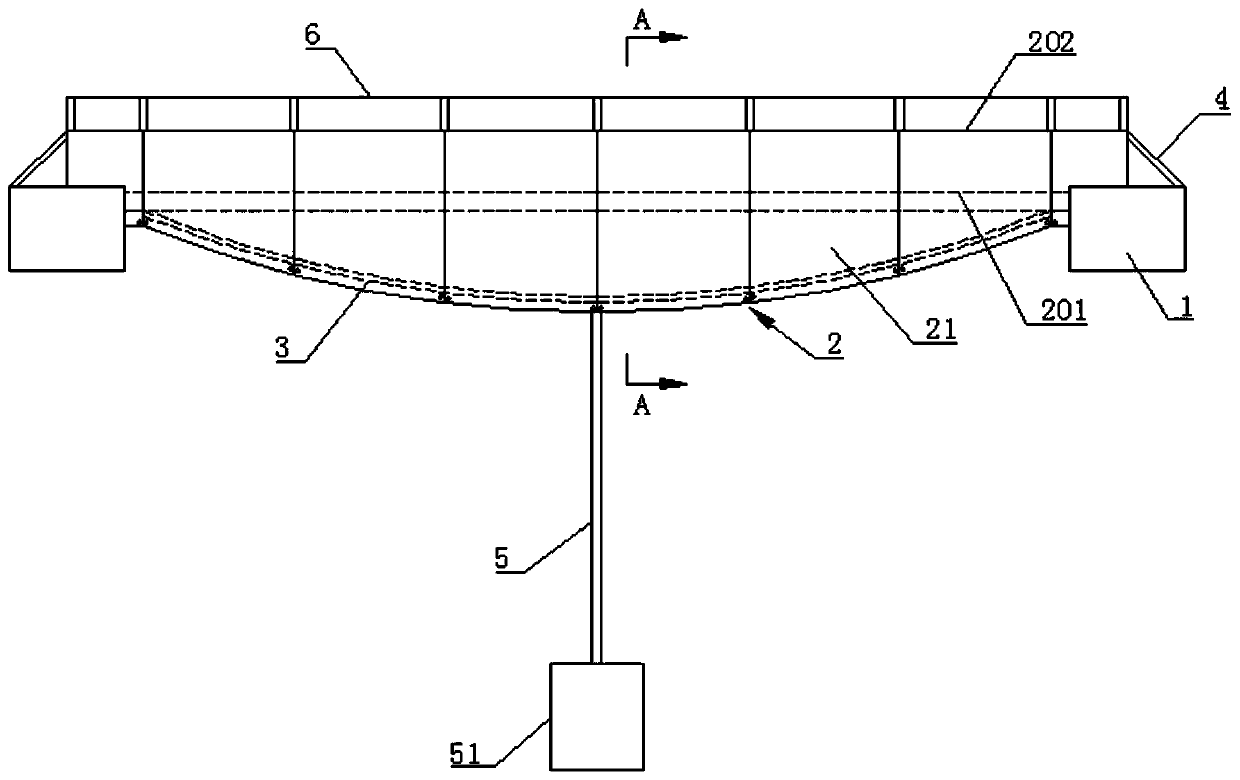

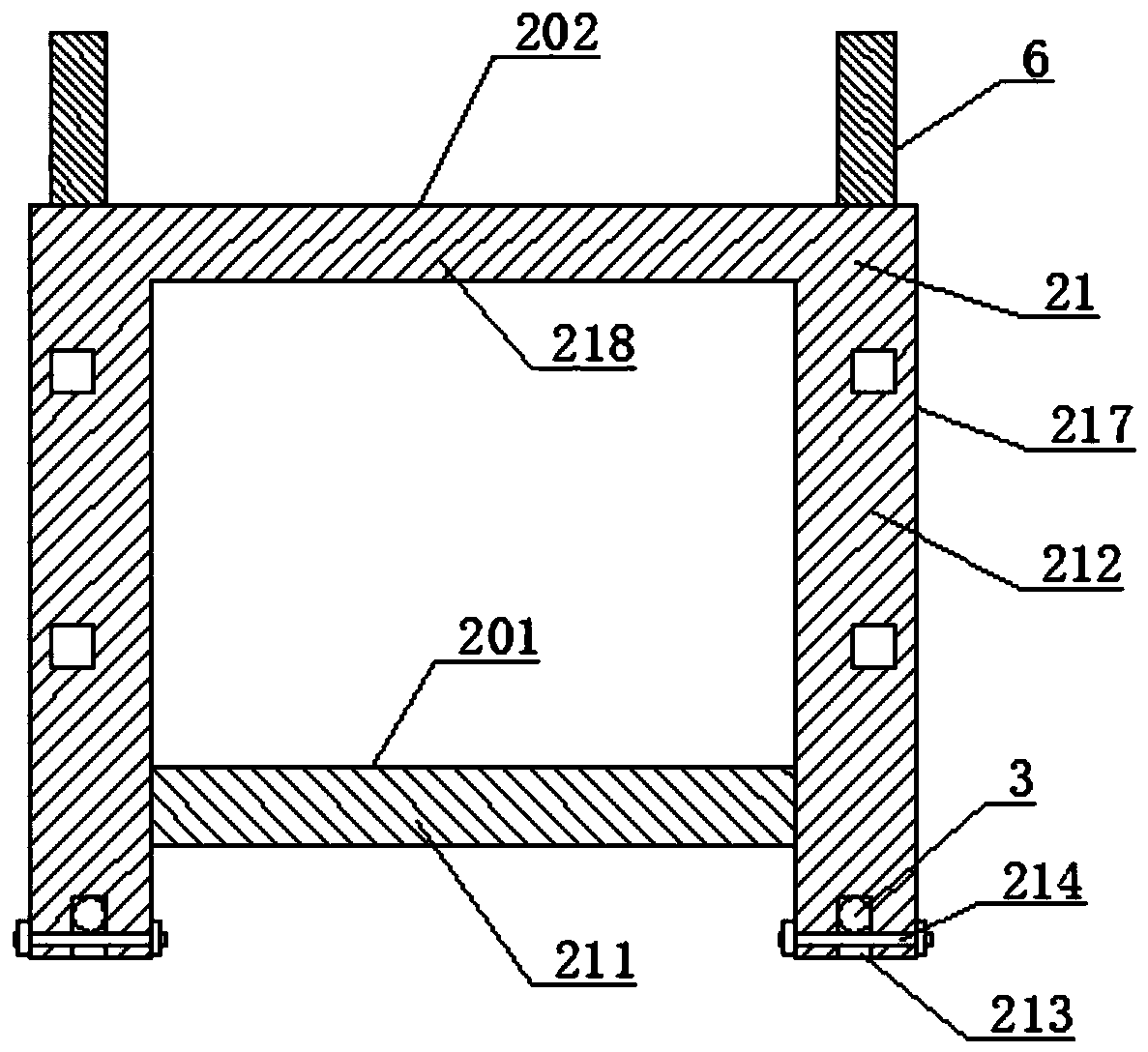

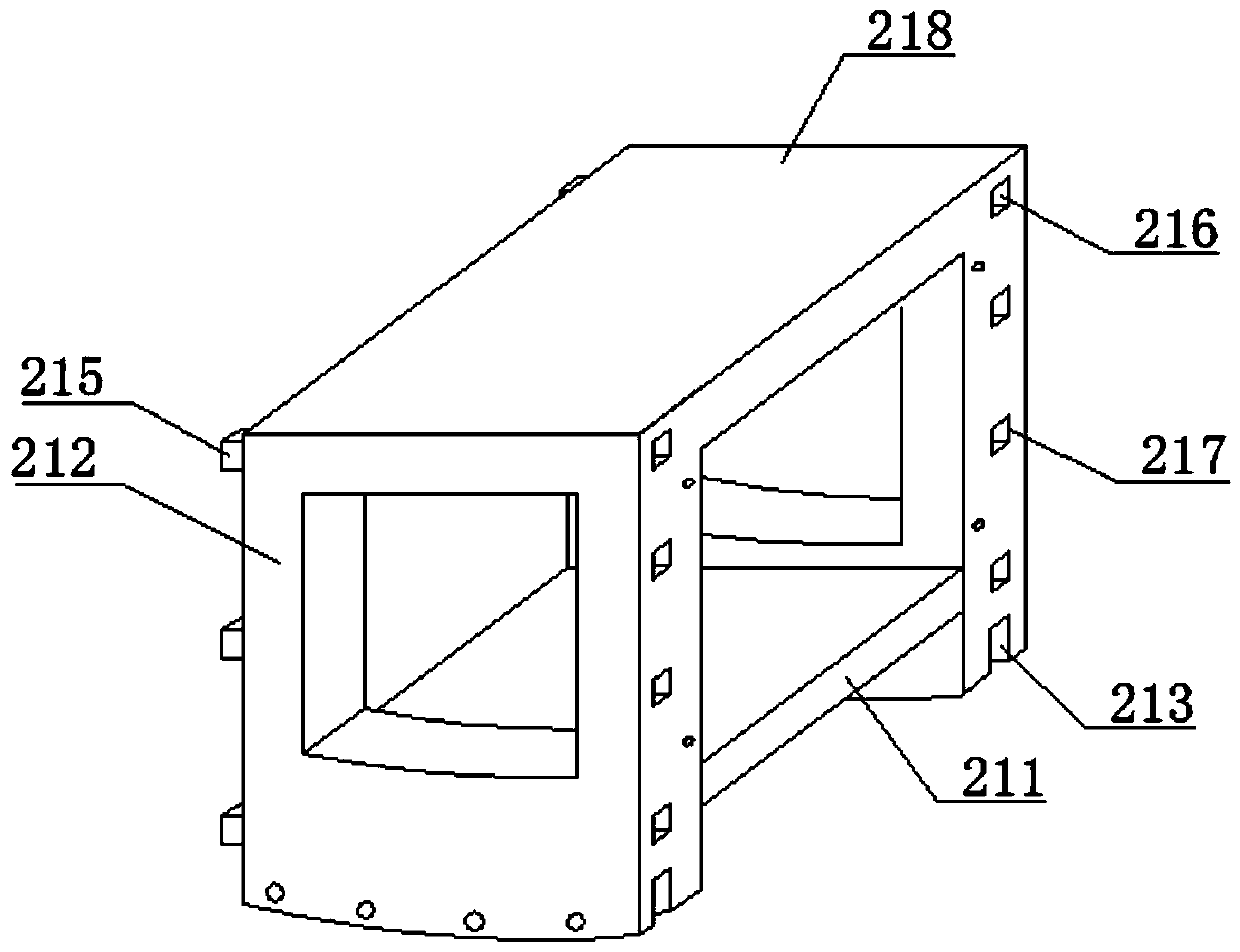

[0029] Such as Figure 1 to Figure 3 As shown, a cable-stayed bridge includes a bridge pier 1 and a bridge body 2 formed by splicing a plurality of bridge body splicing monomers 21. The bottom of the bridge body 2 is curved in an arc, and at least one passageway parallel to the horizontal plane is provided on the bridge body. The two ends of the bridge body 2 are fixed on the bridge pier 1, and steel cables 3 are installed between the bridge piers 1. The number of steel cables 3 is at least two, and the steel cables 3 pass through the bottom of the bridge body 2, and the bridge body splicing is single. Body 21 spans between two steel cables.

[0030] The bridge body splicing units 21 are fixedly connected by connectors, the bottom of the bridge body splicing units 21 adapts to the curvature of the bridge body, and the bridge body splicing units 21 are provided with a horizontal first passage board bordering the road surface 211 , the first passage plates 211 of the plurality ...

Embodiment 2

[0041] Such as Figure 4 As shown, compared with the first embodiment, the present embodiment has a plurality of piers 1 and bridge bodies 2, and is a large-scale cable-stayed bridge formed by butt joints of the cable-stayed bridges in the first embodiment.

[0042] The bridge body 2 is erected between two adjacent piers 1, and the structure and connection between the bridge piers 1 and the bridge body 2 are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com