Bio-based fully-degradable insect-resistant mulch

A fully degradable, bio-based technology, applied in plant protection, plant protection covers, botanical equipment and methods, etc., can solve the problem of incomplete degradation and achieve controllable degradation time and speed, low cost, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

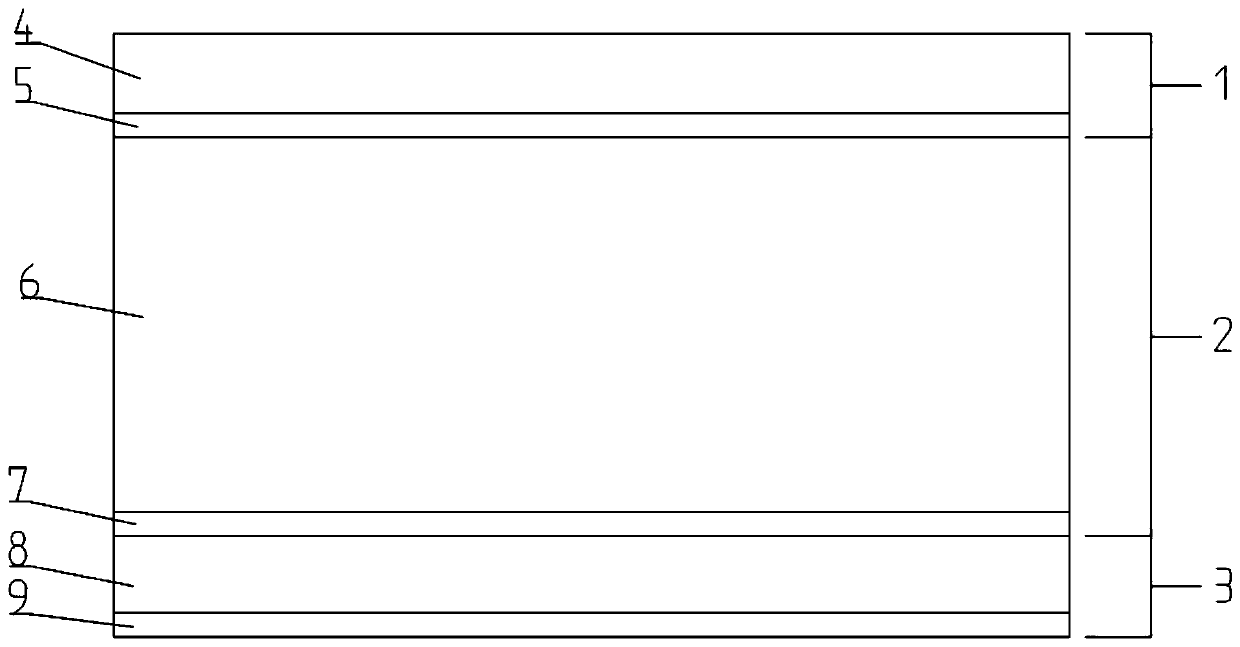

[0025] A bio-based fully degradable insect-proof mulch film, including a surface layer, a middle layer, and an inner layer;

[0026] The surface layer includes a surface resin layer and a surface additive layer, the surface additive layer is located below the surface resin layer, the surface resin layer is a modified polyvinyl alcohol resin, and the surface additive layer is an oxidative photodegradation additive;

[0027] The middle layer includes a middle resin layer and a middle additive layer, the middle additive layer is located below the middle resin layer, the middle resin layer is a modified polylactic acid resin, and the middle additive layer is an oxidative thermal degradation additive;

[0028] The inner layer includes an inner layer resin layer and an inner layer additive layer, the inner layer additive layer is located below the inner layer resin layer, the inner layer resin layer is a modified polyhydroxyalkanoate resin, and the inner layer additive layer The lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com