Self-adaptive water mist dust removal system for casting workshop

A dust removal system and self-adaptive technology, applied in the direction of using liquid separating agent, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of smoke and dust escaping, insufficient adaptability, endangering the health of operators, etc., and achieve uniform velocity at the tuyere , prevent uneven distribution of air volume, and isolate the effect of high temperature casting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

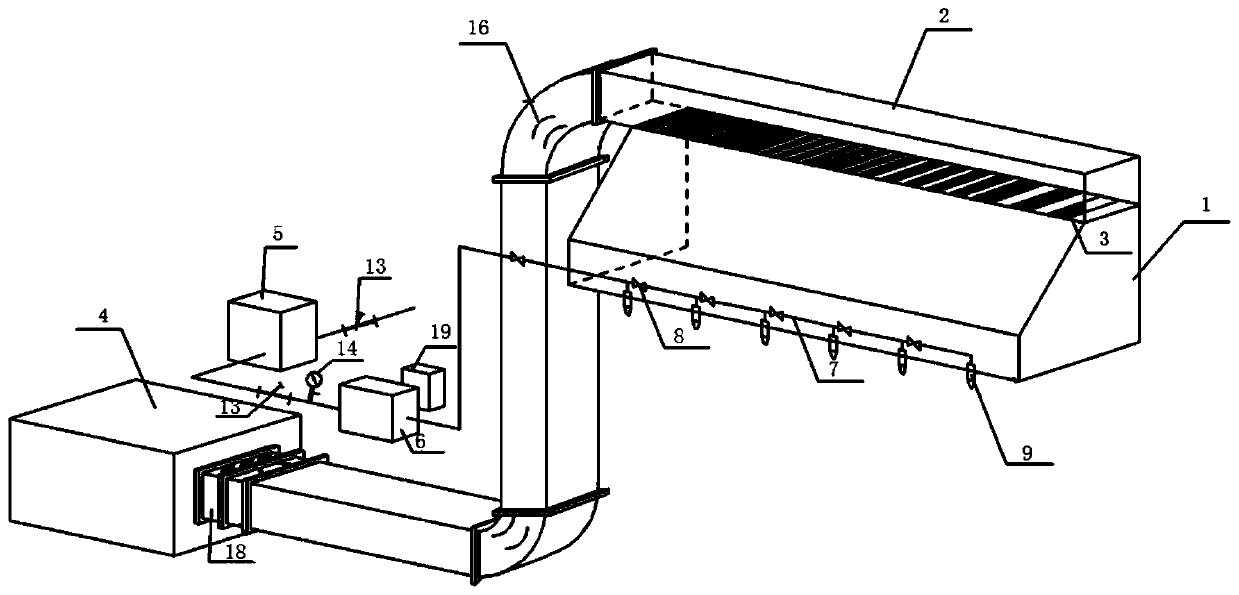

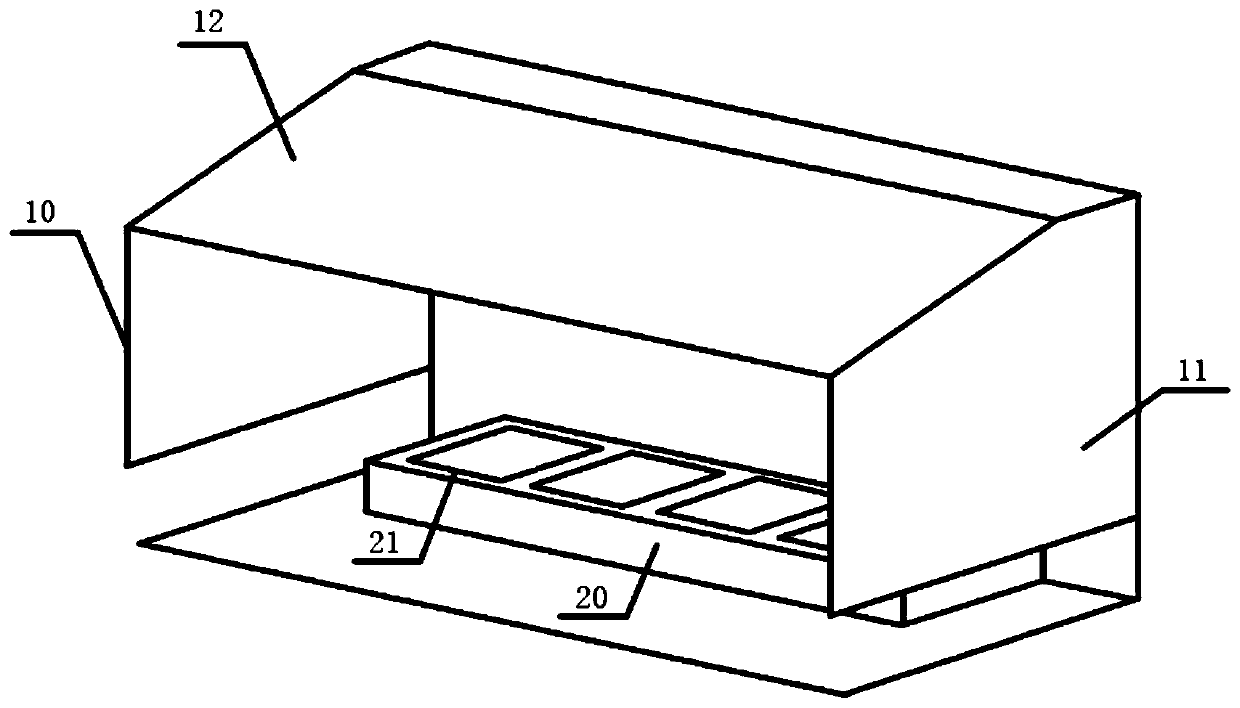

[0047] This embodiment discloses an adaptive water mist dust removal system for a casting workshop, including a water mist curtain generation module and an exhaust module, and the water mist curtain generation module is used to generate a water mist curtain to block the smoke and dust emitted by the casting workshop And reduce the temperature of the smoke and dust, the exhaust module is used to take away the smoke and dust isolated by the water mist curtain generating module;

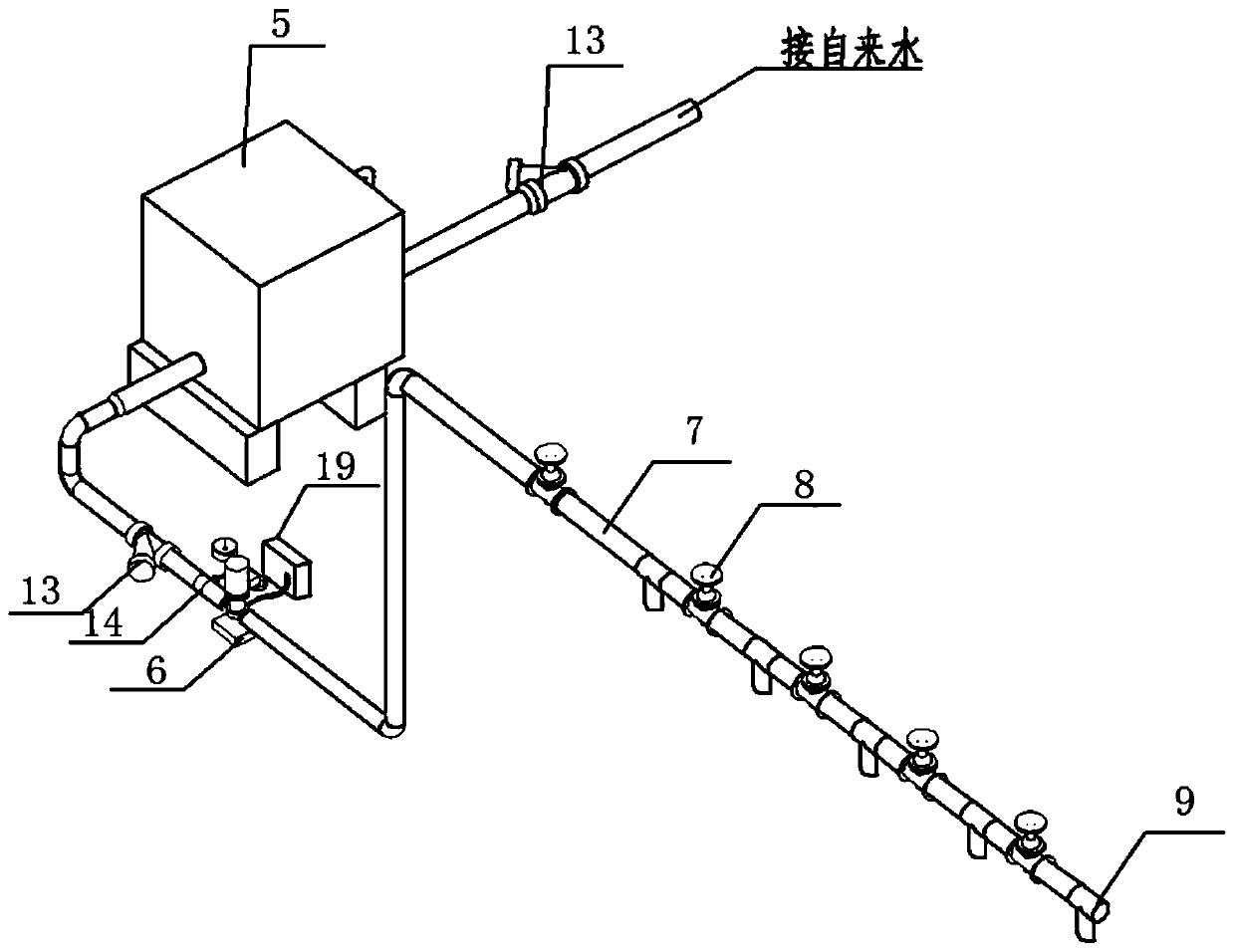

[0048] The exhaust module includes an exhaust hood 1, an exhaust pipe 2, a tuyere 3 and a fan 4, the exhaust hood 1 is arranged in the casting workshop, the exhaust pipe 2 includes a front section and a rear section, and the exhaust The front section of the pipe 2 is arranged in the exhaust hood 1 and is divided into n pipe sections according to the number n of casting molds contained in the casting workshop. Each pipe section is provided with a plurality of tuyere 3 and the total area of the tuyere of...

Embodiment 2

[0073] This embodiment discloses an adaptive water mist dust removal system for a casting workshop. On the basis of Embodiment 1, the following technical features are also disclosed:

[0074] In the present embodiment, there are four casting molds emitting high-temperature smoke and dust below the exhaust hood 1 and the side length of the mold is 2 meters. The longer the distance of the air duct, the greater the resistance along the way. With the increase of the distance of the air duct, the air volume will be greatly reduced, resulting in uneven distribution of air volume in the front and rear sections of the exhaust duct. Therefore, there is often a case where the exhaust hood 1 is effective in controlling the high-temperature smoke and dust emitted by the first casting mold, but the effect becomes worse as it goes further. In view of this problem, in this embodiment, the exhaust pipe 2 is divided into four sections, and slit-type air outlets at different intervals are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com