Aluminum cylinder head guide pipe reaming process device

A process device and cylinder head technology, applied in reaming devices, reaming devices, manufacturing tools, etc., can solve problems such as unstable processing, hidden safety hazards, and affecting the accuracy of reaming processing, so as to improve accuracy and stability, The effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The content of the present invention will be described below in conjunction with specific embodiments.

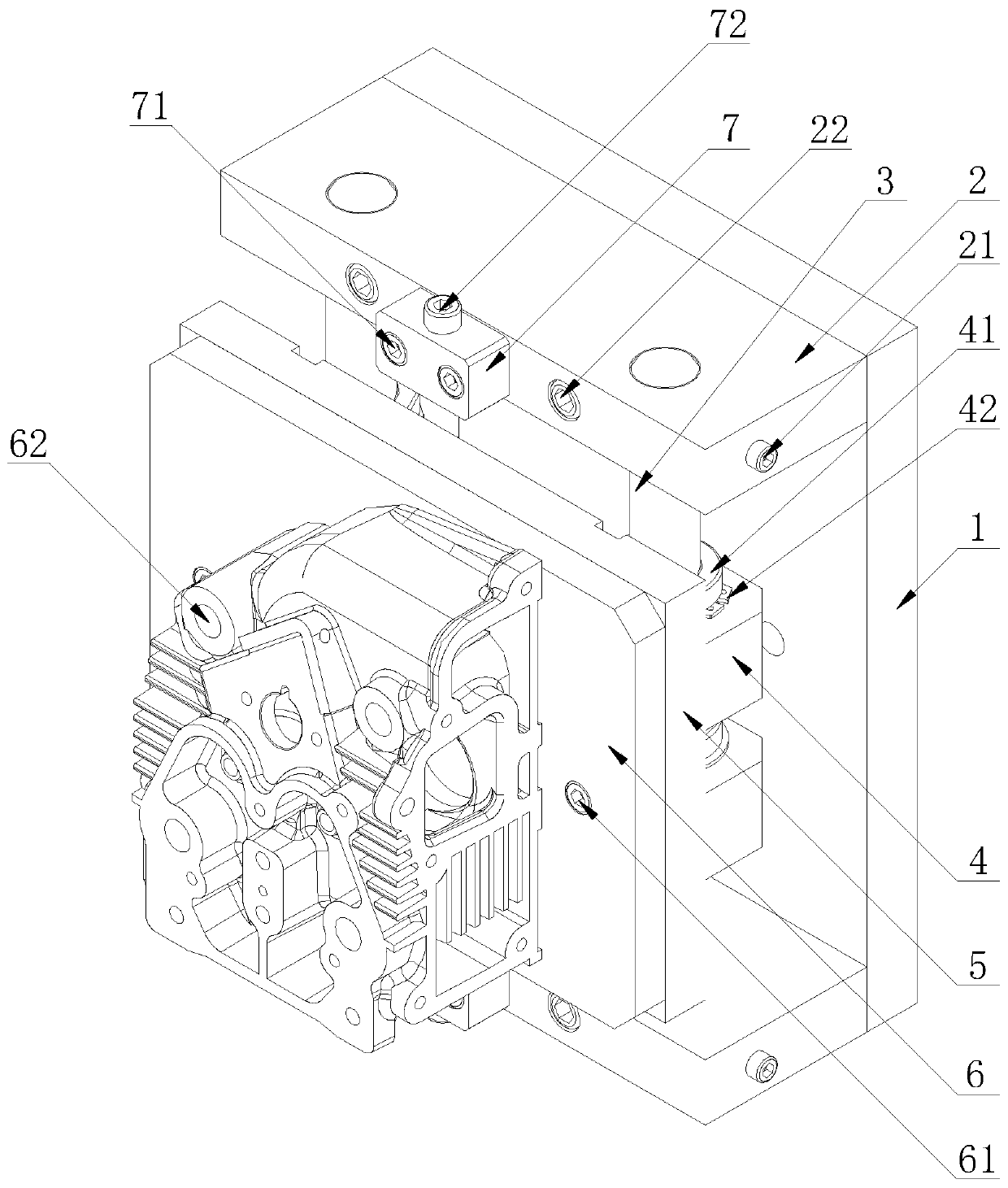

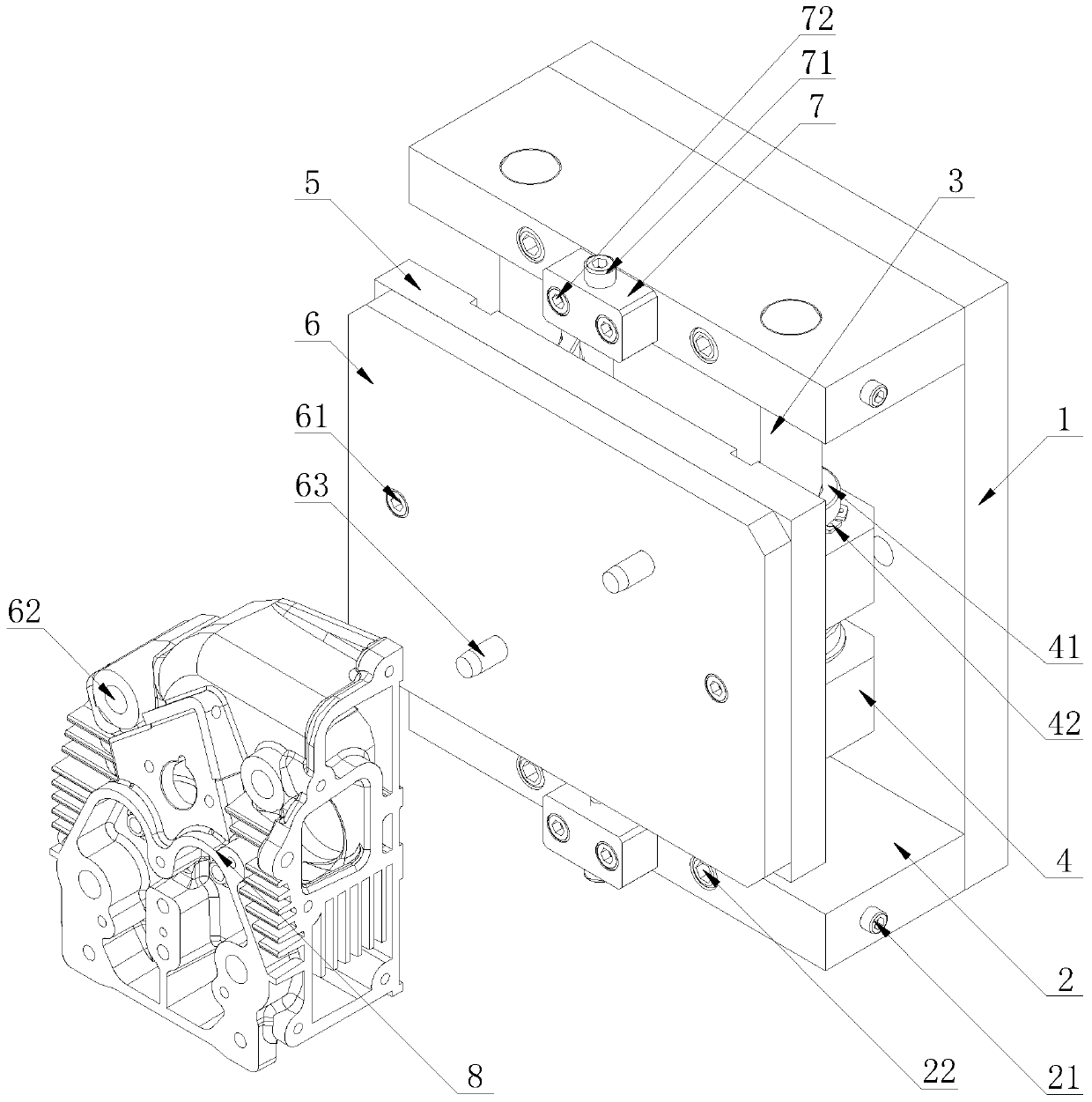

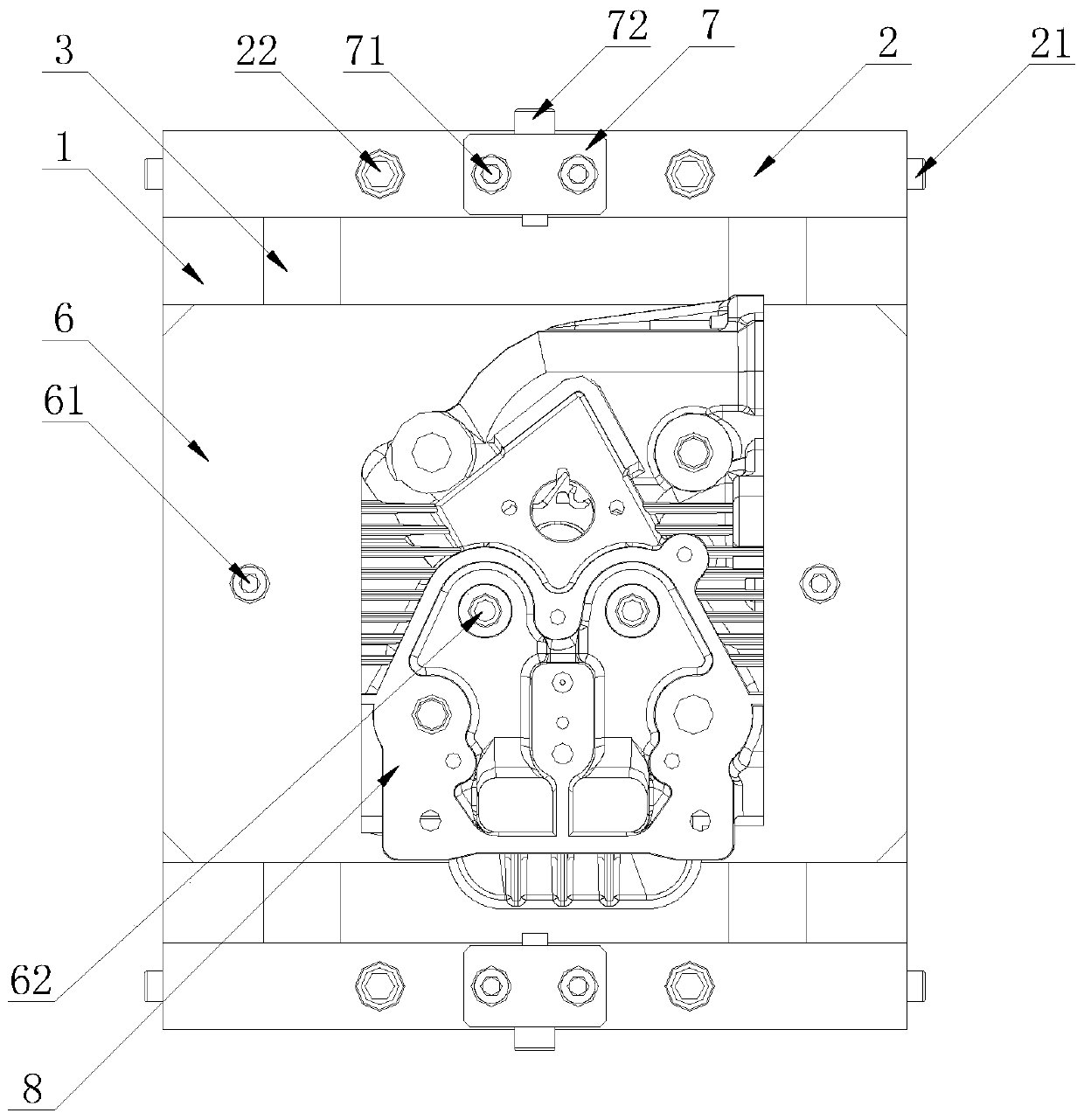

[0023] figure 1 It is a schematic diagram of the clamping structure of the process device of the present invention, figure 2 It is a schematic structural view of the process device of the present invention, such as figure 1 and figure 2 As shown, the process device of the present invention is installed on the machine tool for positioning and clamping the cylinder head 8, including: a tooling base plate 1 fixed on the machine tool, a pair of support plates symmetrically fixed on the top and bottom of the tooling base plate 1 2. The vertical shaft 3 installed between the support plates 2, the bearing seat 4 slidingly connected with the vertical shaft 3, the sliding table bottom plate 5 fixed on the outer wall of the bearing seat 4, and the sliding table bottom plate fixed on the bottom sliding table 5 on the positioning plate 6. There are many vertical shafts 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com