PTC heating module for heating a fluid

A heating module, heating fluid technology, applied in air heaters, heat storage heaters, fluid heaters, etc., can solve the problems of increasing resistance, inability to dissipate heat energy, and increased heating of PTC thermistor elements, and improve heating performance. , the effect of reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

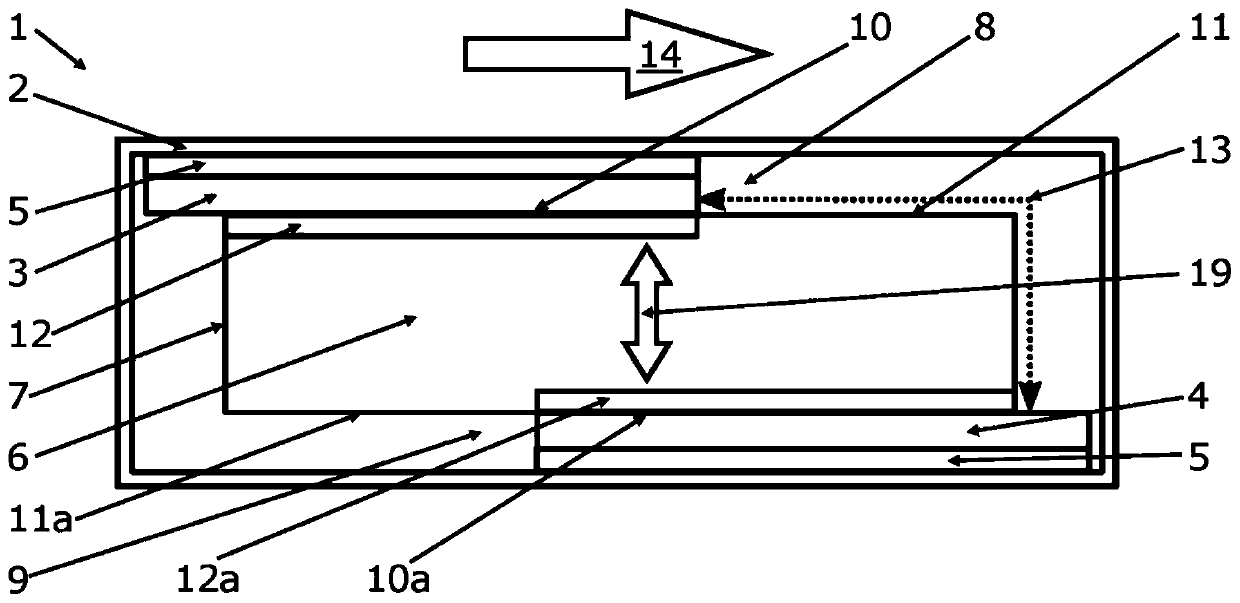

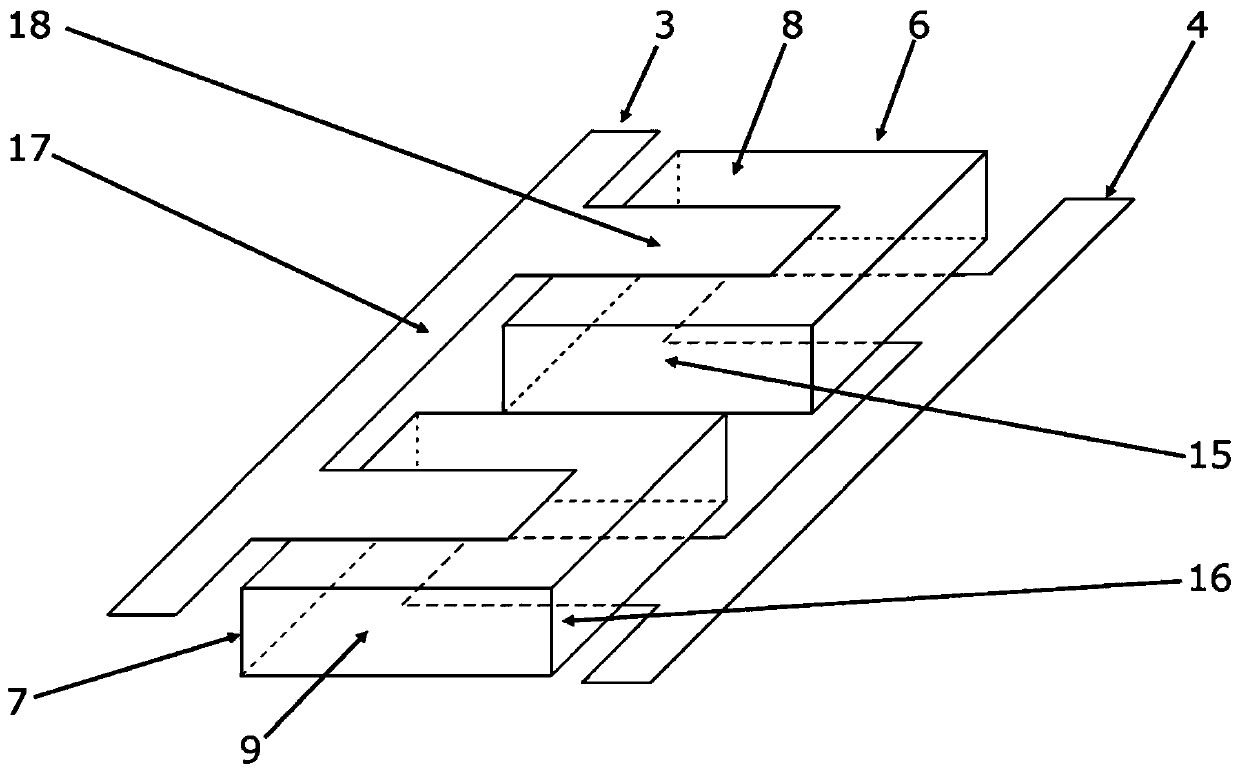

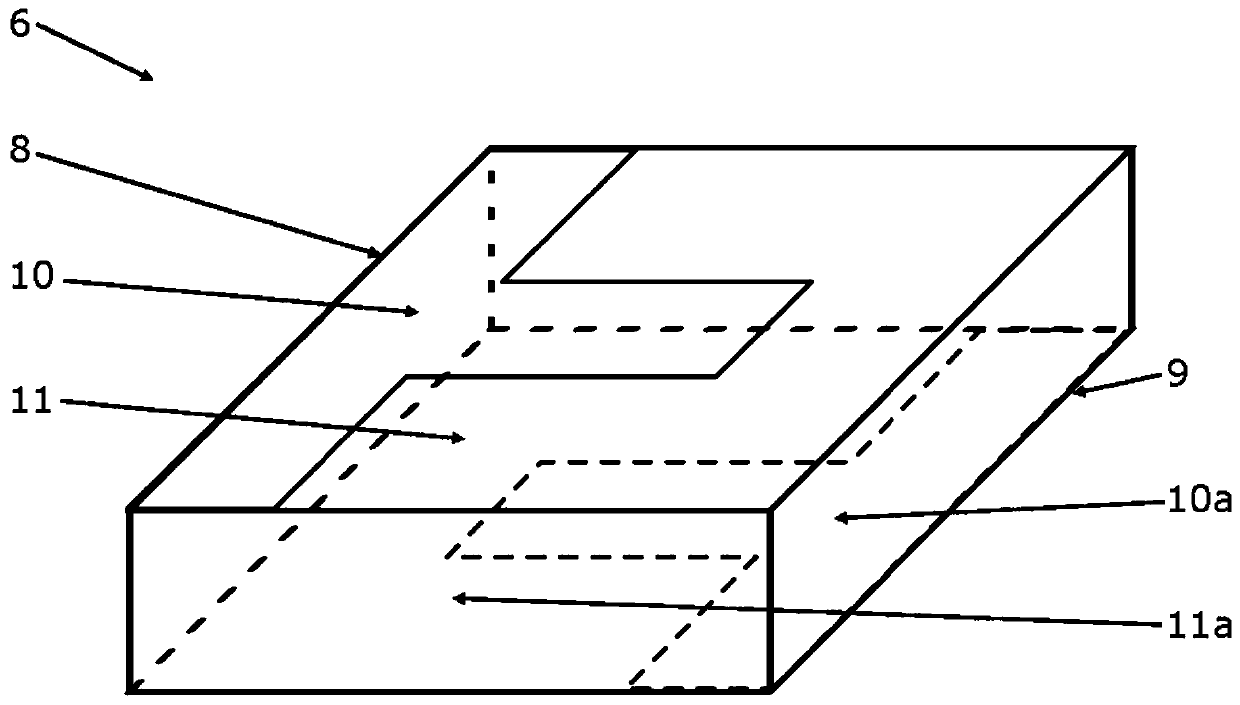

[0043] according to figure 1 , the PTC heating module 1 according to the invention has a housing 2 with a rectangular cross-section. The first electrically conductive contact electrode 3 and the second electrically conductive contact electrode 4 are arranged spaced apart from one another in the housing 2 . If the housing 2 consists of an electrically conductive material, an insulating layer 5 is arranged between the respective contact electrodes 3 , 4 and the housing 2 . The insulating layer 5 prevents an electrically conductive connection between the contact electrodes 3 , 4 and the housing 2 . Such as figure 1 As shown, the insulating layer 5 may be provided on a part of the surface of the housing 2 . It is also conceivable to arrange the insulating layer 5 entirely on the inner surface of the housing 2 .

[0044] Such as figure 1 As shown, the rectangular parallelepiped PTC thermistor element 6 is arranged between the first contact electrode 3 and the second contact el...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap