A centrifugal destoned grain microwave drying device

A microwave drying and grain technology, applied in grain drying, drying solid materials, heating to dry solid materials, etc., can solve the problems of insufficient compact structure, simple drying module structure, poor removal effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

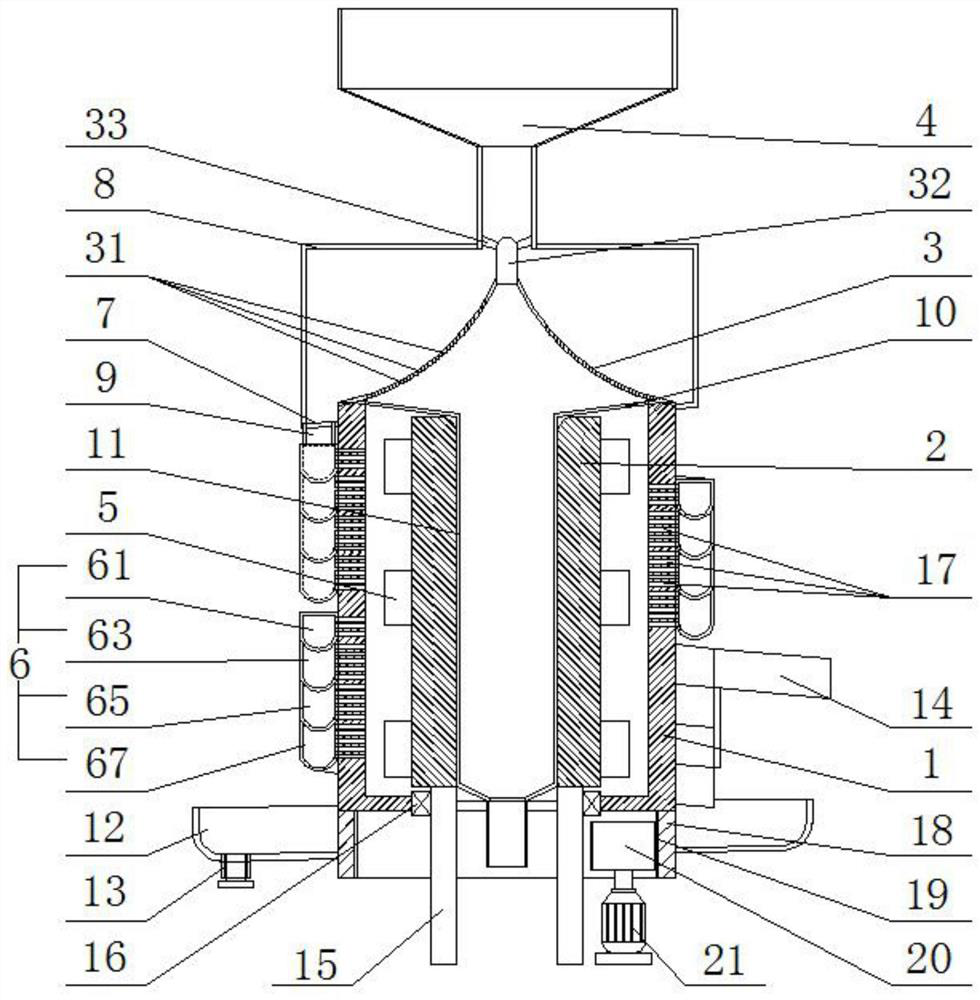

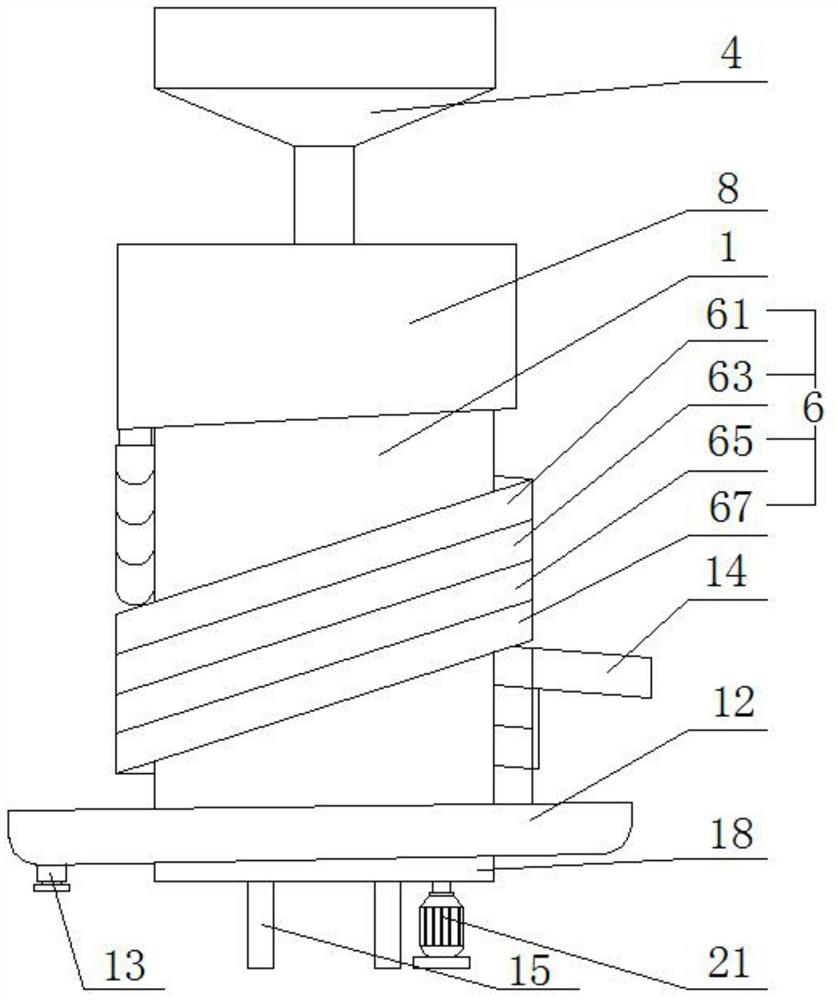

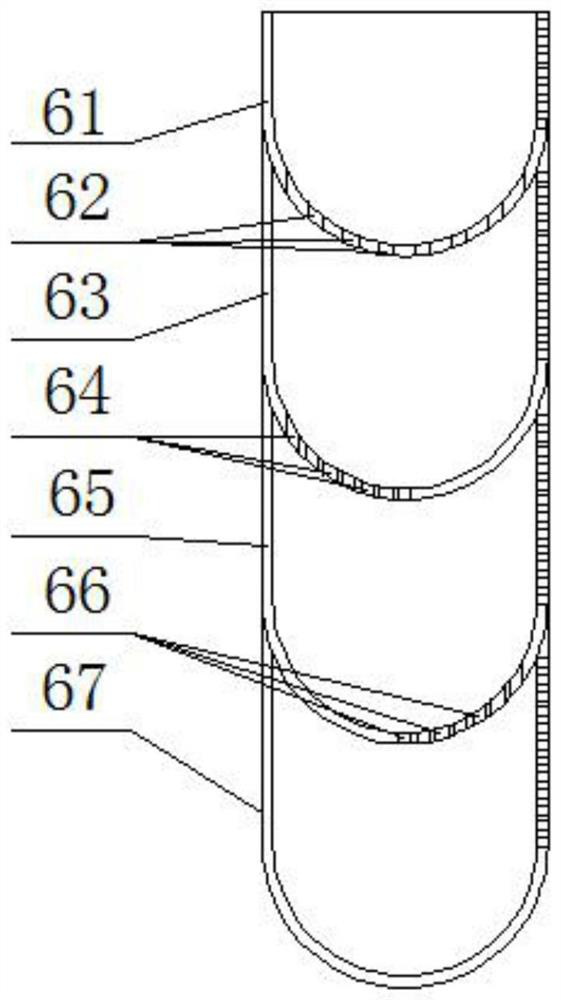

[0025] Such as figure 1 and figure 2 A centrifugal destoned grain microwave drying device shown includes a cylindrical outer rotating cylinder 1, a fixed cylinder 2 arranged inside the outer rotating cylinder 1, a fine stone sieve plate 3 connected to the top of the outer rotating cylinder 1, The feed hopper 4 arranged above the middle part of the fine stone sieve plate 3, the microwave generator 5 evenly fixed on the outer surface of the fixed cylinder 2, and the grain channel 6 spirally wound and fixed on the outer surface of the outer rotating cylinder 1 from top to bottom, The structure of the fine stone sieve plate 3 is a concave curved surface gradually lowering from the middle to the peripheral side, and the fine stone sieve plate 3 is evenly distributed with first openings 31 whose apertures are smaller than the particle diameter of grains. The top of cylinder 1 is fixed with a material receiving plate 7 surrounding the bottom outside of the fine stone sieve plate 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com