A series magnetic circuit hybrid permanent magnet memory motor

A memory motor and magnetic circuit technology in series, applied in the direction of magnetic circuit, magnetic circuit rotating parts, magnetic circuit static parts, etc., can solve the problems of high demagnetization current and low magnetic adjustment performance, and achieve low demagnetization current and low rotor speed. Lifting, the effect of increasing the adjustment range of the magnetization state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

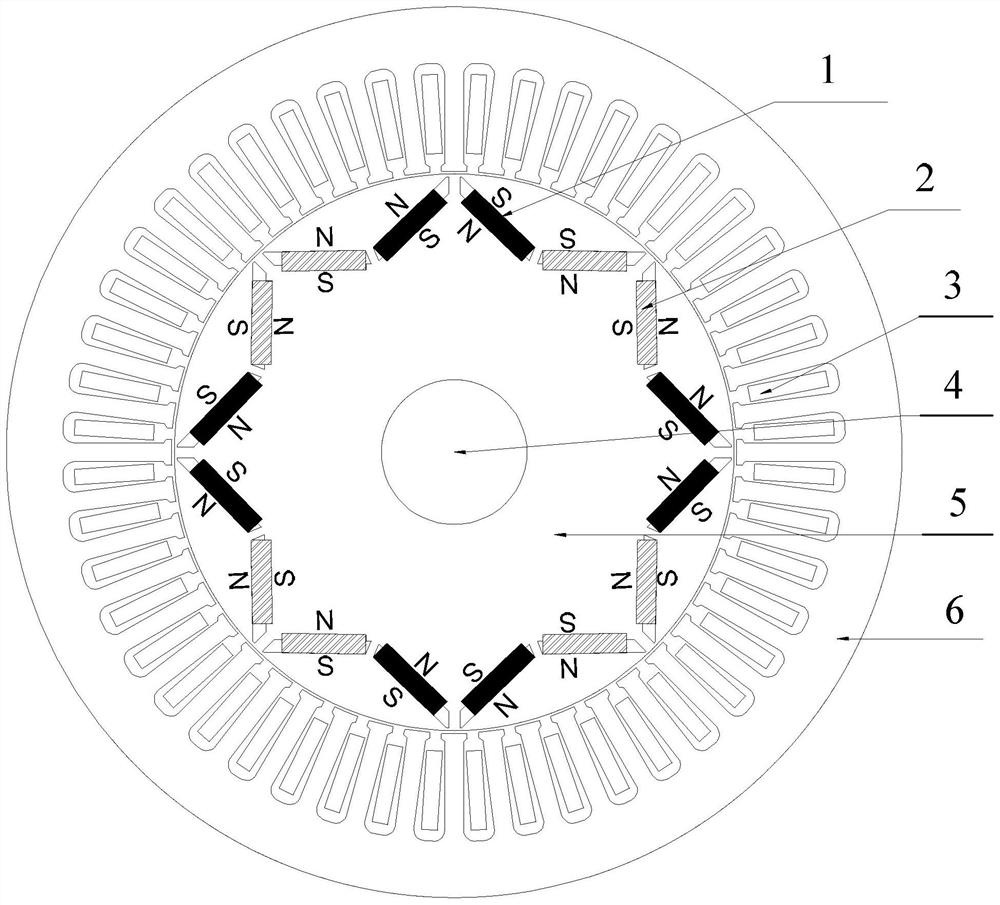

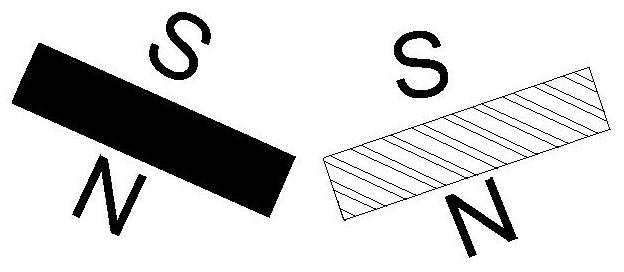

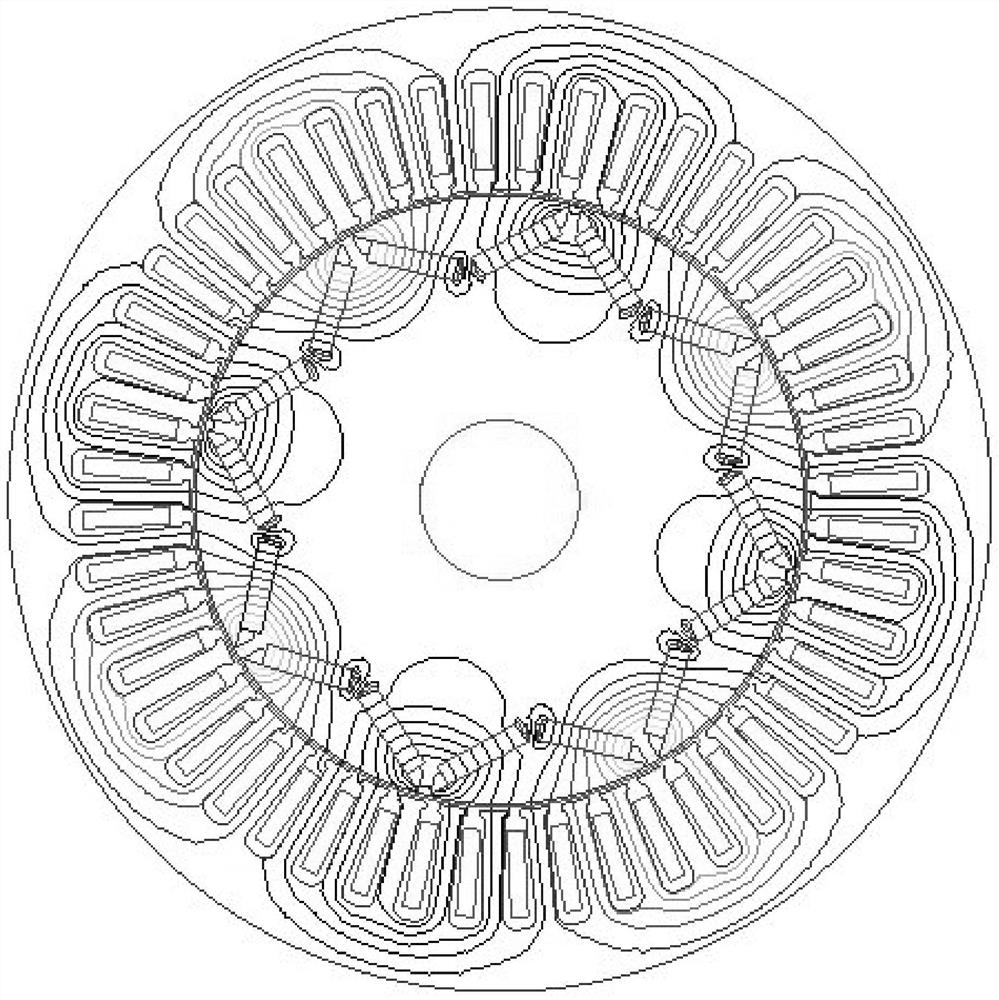

[0020] Specific implementation mode one: refer to figure 1 and figure 2 Specifically explain this embodiment, a series magnetic circuit hybrid permanent magnet memory motor described in this embodiment includes: an even number of permanent magnet units, a winding 3, a rotating shaft 4, a rotor core 5 and a stator core 6;

[0021] Each pole permanent magnet unit includes two permanent magnets with the same magnetization direction, the two permanent magnets are arranged in a "V" shape, and the angle range of the "V" shape of the two permanent magnets is 120°-135°, further , the optimal value is 130°;

[0022] The rotor core 5 is coaxially sleeved on the outer circumference of the rotating shaft 4, the stator core 6 is coaxially sleeved on the outer circumference of the rotor core 5, the inner circumference of the stator core 6 is provided with a plurality of stator teeth, and the winding 3 is embedded in multiple Between the two stator teeth, the rotor core 5 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com