Apparatus and method for producing poly-alpha-olefin by continuous process

A continuous method and olefin technology, applied in chemical instruments and methods, base materials, hydrocarbons, etc., can solve problems affecting product composition, difficulty in mixing and removing heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] As a preferred embodiment, the device further includes a liquid level controller and / or a temperature controller for monitoring the liquid level and / or temperature in the catalyst preparer and the multistage reactor respectively.

[0042] Another aspect of the present invention provides a kind of method utilizing above-mentioned device to produce polyalphaolefin, this method comprises:

[0043] Catalyst and accelerator are mixed in the catalyst preparer to obtain catalyst complex, which enters the first-stage reactor through the catalyst metering pump, and carries out the first-stage polymerization reaction with α-olefin dissolved and mixed with the catalyst , the obtained first-stage polymerization product enters the follow-up reactor through the discharge pump, and finally obtains polyalphaolefin;

[0044] Among them, the heat generated in the catalyst preparer and reactors of all stages is withdrawn through the chilled water unit.

[0045] According to the present i...

Embodiment 1

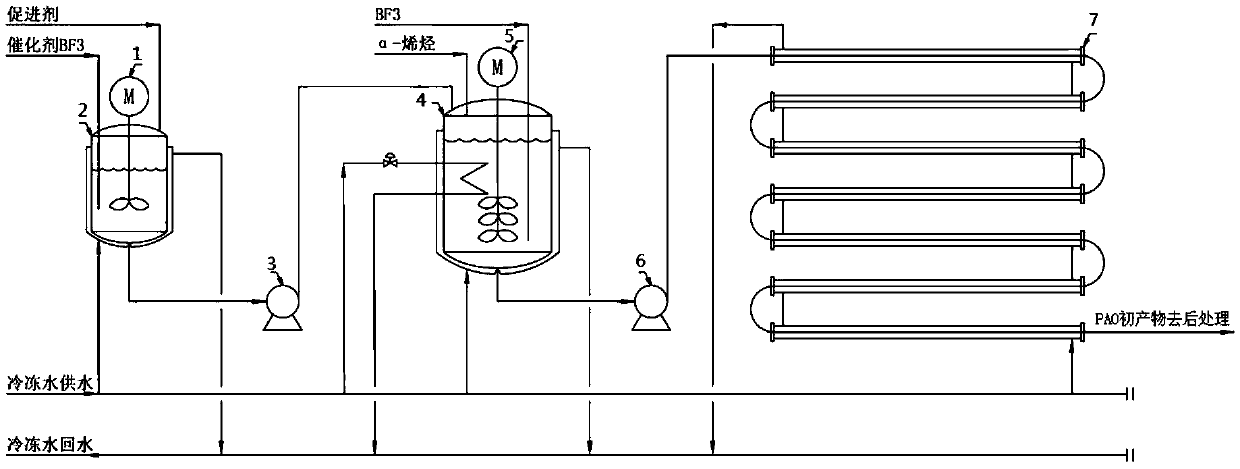

[0058] Such as figure 1 As shown, the present embodiment provides a device for continuous production of polyalpha-olefins, the production device includes: a batch catalyst preparer (only one is shown in the figure), and the catalyst preparer 2 includes a tank body and a first stirring Mechanism 1, the first stirring mechanism 1 includes a stirring shaft extending vertically downward from the top of the tank to the bottom of the tank, a stirring paddle arranged on the stirring shaft and driving the stirring shaft and stirring The power unit that the paddle rotates; the tank body is also provided with a catalyst feed port, a promotor feed port, a material outlet, a temperature measurement port and a liquid level measurement port; a cooling jacket and a cooling cavity is formed between the tank body;

[0059] Two reactors connected in series, a discharge pump 6 is arranged between the two reactors; wherein, the first stage of the two reactors is a stirred tank reactor, and the s...

Embodiment 2

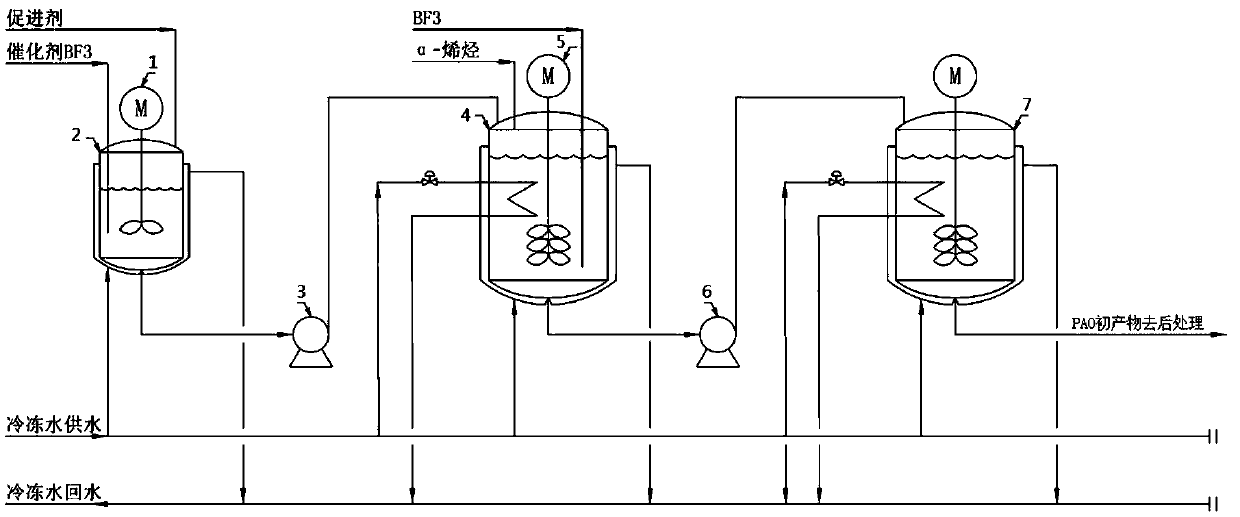

[0066] Such as figure 2 As shown, the difference between this embodiment and embodiment 1 is that the second-stage reactor 7 is a stirred tank reactor, and other devices and production methods are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com