Heterogeneous high-entropy alloy material and preparation method thereof

A high-entropy alloy and heterogeneous technology, which is applied in the field of heterogeneous high-entropy alloy materials and their preparation, can solve the problems of cumbersome process of composite plates, low production efficiency, etc., and achieves low cost, high recovery rate and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

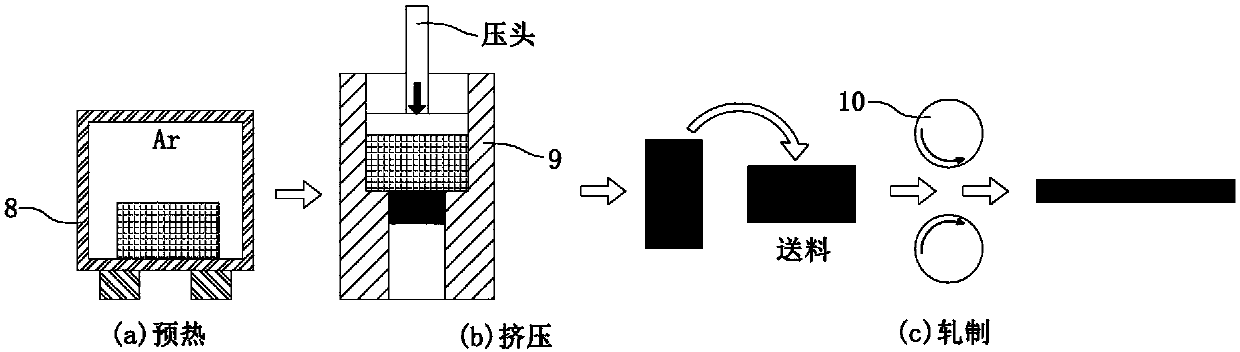

[0029] Such as Figure 1-4 As shown, the following embodiments include four steps, respectively: chip making, chip mixing and pre-compaction, plastic deformation treatment, annealing treatment, wherein:

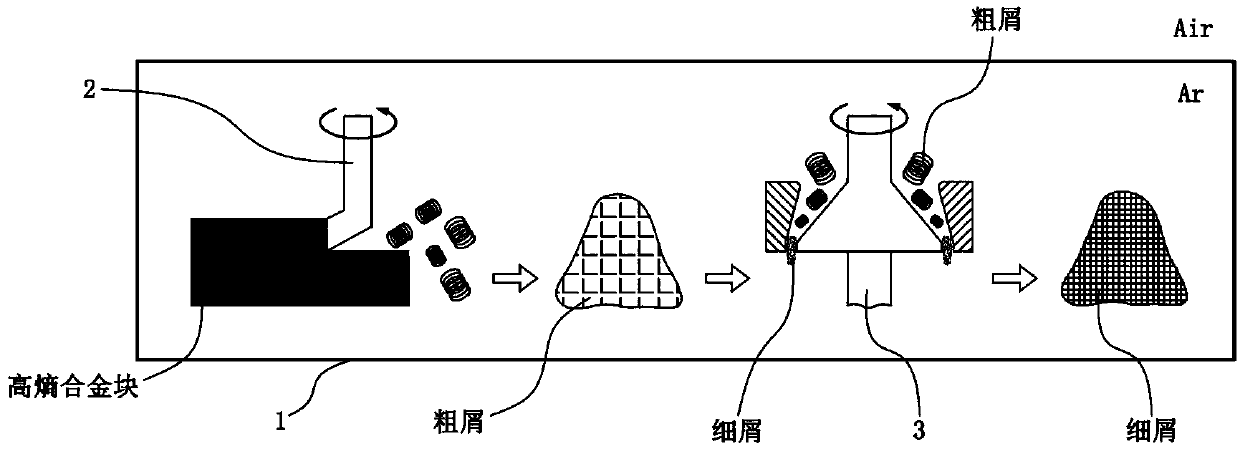

[0030] Such as figure 1 As shown, in a vacuum glove box 1 filled with argon protection, using a micro vertical milling machine 2 to pair CoCrFeNiMn (face-centered cubic single-phase structure) and Al 0.3 CoCrFeNi (face-centered cubic + body-centered cubic dual-phase structure) two high-entropy alloys were used for chip preparation, and the milling feed rate was 0.2 mm to obtain coarse chips with a thickness of about 0.2 mm. Then use the micro-crusher 3 to finely crush the milled coarse chips, reduce and uniform the length of the chips to 0.2-0.3mm for later use.

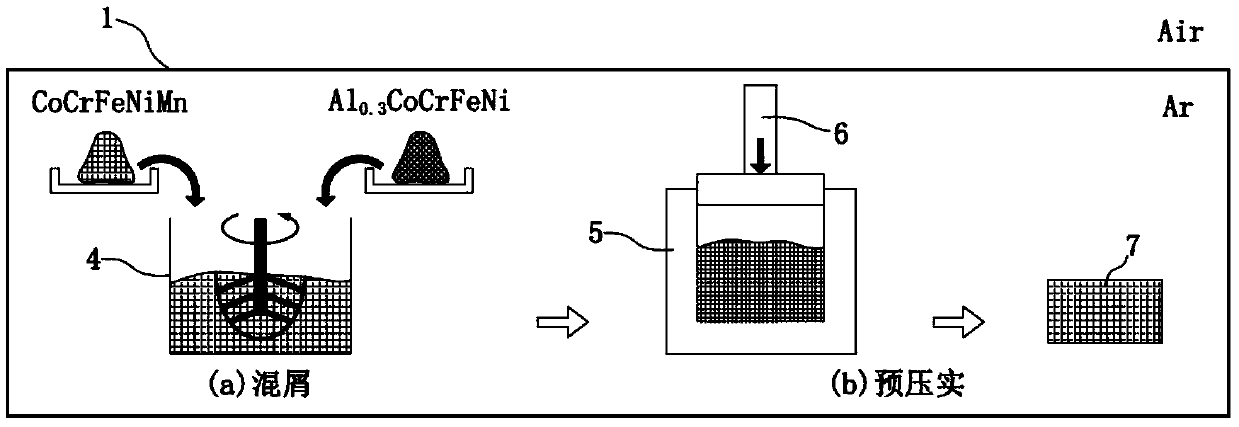

[0031] Such as figure 2 As shown, in a vacuum glove box 1 filled with argon protection, the CoCrFeNiMn and Al 0.3 The CoCrFeNi high-entropy alloy chips are mechanically alloyed and mixed by vibrating, stirring,...

Embodiment 2

[0035] Such as Figure 1-4 As shown, the following embodiments include four steps, respectively: chip making, chip mixing and pre-compaction, plastic deformation treatment, annealing treatment, wherein:

[0036] Such as figure 1 As shown, in a vacuum glove box 1 filled with argon protection, using a micro vertical milling machine 2 to pair CoCrFeNiMn (face-centered cubic single-phase structure) and Al 0.3 CoCrFeNi (face-centered cubic + body-centered cubic dual-phase structure) two high-entropy alloys were used for chip preparation, and the milling feed rate was 0.1 mm to obtain coarse chips with a thickness of about 0.1 mm. Then use the micro-crusher 3 to finely crush the milled coarse chips, reduce and uniform the length of the chips to 0.1-0.2mm for later use.

[0037] Such as figure 2 As shown, in a vacuum glove box 1 filled with argon protection, the CoCrFeNiMn and Al 0.3 The CoCrFeNi high-entropy alloy chips are mechanically alloyed and mixed by vibrating, stirring, s...

Embodiment 3

[0041] Such as Figure 1-4 As shown, the following embodiments include four steps, respectively: chip making, chip mixing and pre-compaction, plastic deformation treatment, annealing treatment, wherein:

[0042] Such as figure 1 As shown, in a vacuum glove box 1 filled with argon protection, using a micro vertical milling machine 2 to pair CoCrFeNiMn (face-centered cubic single-phase structure) and Al 0.3 CoCrFeNi (face-centered cubic + body-centered cubic dual-phase structure) two high-entropy alloys were used for chip preparation, and the milling feed rate was 0.1 mm to obtain coarse chips with a thickness of about 0.1 mm. Then use the micro-crusher 3 to finely crush the milled coarse chips, reduce and uniform the length of the chips to 0.1-0.2mm for later use.

[0043] Such as figure 2 As shown, in a vacuum glove box 1 filled with argon protection, the CoCrFeNiMn and Al 0.3 The CoCrFeNi high-entropy alloy chips are mechanically alloyed and mixed by vibrating, stirring,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com