Suspension embroidery frame device of computerized embroidery machine

An embroidery machine and embroidery frame technology, applied in the field of a computerized embroidery machine suspended embroidery frame device, can solve the problems of easy wear, reduced life of the embroidery frame, wear of the embroidery frame components, etc. The effect of running precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

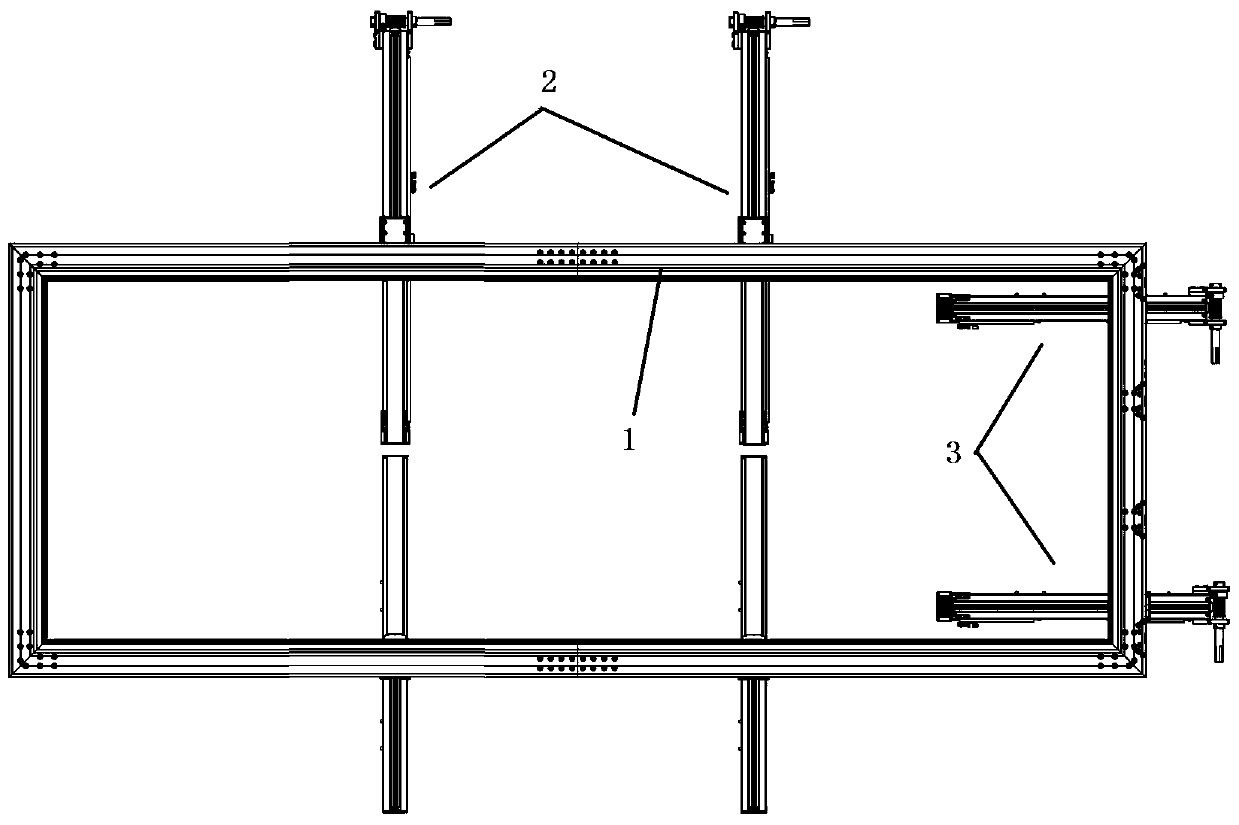

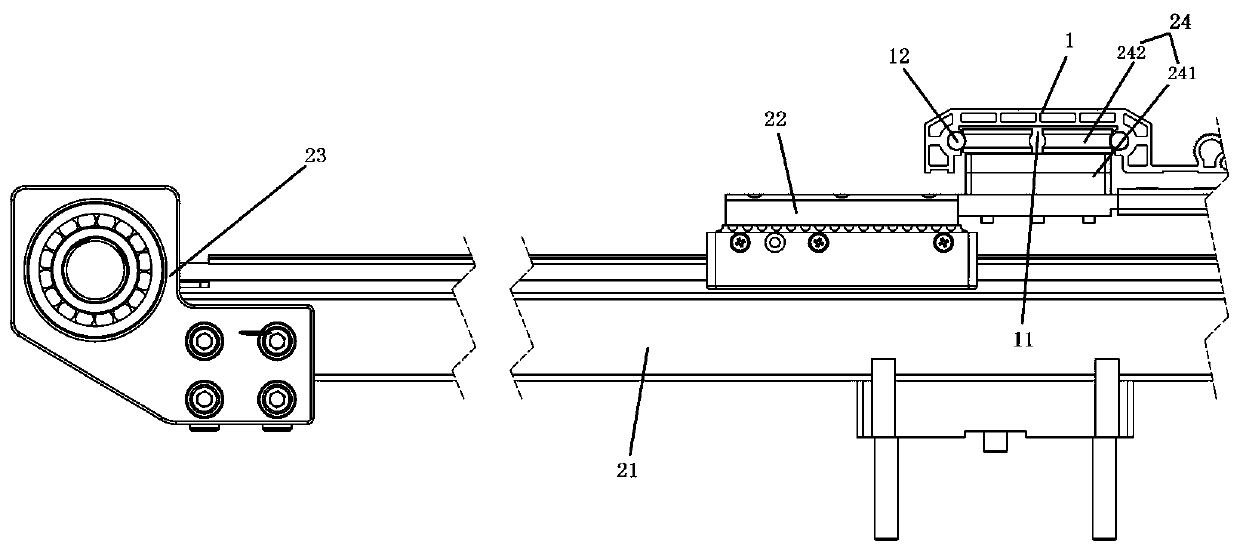

[0040] Such as figure 1 , figure 2 As shown, this embodiment provides a suspended embroidery frame device for a computerized embroidery machine, including:

[0041] The frame 1 includes four side frames that are connected end to end to form a rectangle in turn. The lower surface of the longer side frame extends along its length extension direction to provide a groove 11 with an opening downward. Two of the grooves 11 The longer sides are provided with a protruding portion 12 protruding to the center of the groove 11 with a circular arc surface, and the length extension direction of the protrusion 12 is consistent with the length extension direction of the longer side of the groove 11; wherein The longer side frame is the side frame with a relatively longer length among the four side frames of the frame 1. According to the situation in the prior art, the length of the side frame extending along the X stroke direction of the frame 1 will be longer than that along the Y stroke ...

Embodiment 2

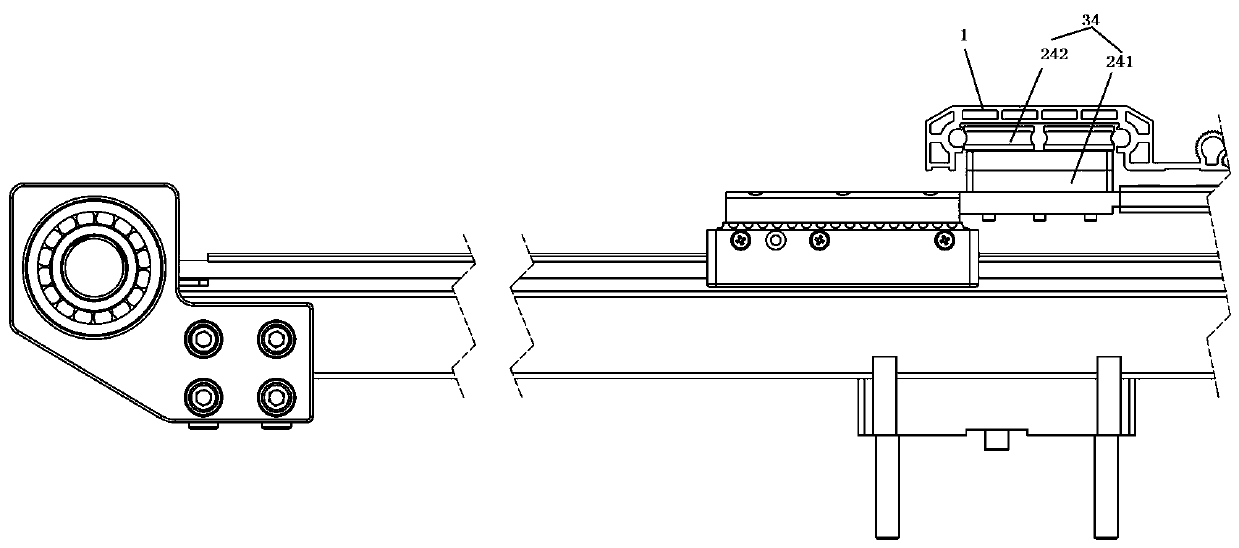

[0049] Such as image 3 As shown, the difference between this embodiment and the previous embodiments is that the lower surface of the shorter side frame in this embodiment extends along its length extension direction to provide a groove 11 with an opening downward, and the groove 11 Both longer sides are provided with a protruding portion 12 protruding to the center of the groove 11 with a circular arc surface, and the length extension direction of the protrusion 12 is consistent with the length extension direction of the longer side of the groove 11 , the X-frame connection assembly 34 includes a connection seat 241 connected to the upper surface of the X driving trolley and a U-shaped bearing 242 horizontally connected to the upper surface of the connection seat 241, and the outer peripheral surface of the U-shaped bearing 242 is recessed and the protruding arc surface of the protruding part 12, and there are at least two U-shaped bearings 242, which are respectively connec...

Embodiment 3

[0052] Such as Figure 4 , Figure 5As shown, the difference between this embodiment and Embodiment 1 is that the X-frame connection assembly 34 in this embodiment includes a Y-direction auxiliary rail 341, several bearing connection parts 342 and a trolley connection part 343, and the Y-direction auxiliary rail 341 is parallel to the shorter side frame and is connected to the shorter side frame through the bearing connecting parts 342 arranged at intervals along the length extension direction of the shorter side frame, and the Y-direction auxiliary rail 341 is lowered The surface is connected to the upper surface of the X driving trolley through the trolley connecting portion 343, specifically, the lower surface of the Y-direction auxiliary rail 341 that is relatively far away from the side of the shorter side frame is connected to the upper surface of the X driving trolley through the trolley connecting portion 343. The upper surface of the X drive trolley is connected, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com