Electromagnetic bidirectional metering pump, hydraulic sliding table and driving method thereof

A metering pump, electromagnetic technology, applied in the field of metering pumps, can solve the problems that the oil port cannot be directly connected to the same driven component, shorten the maintenance cycle of the hydraulic system, increase the volume and weight of the equipment, etc., to reduce the volume and cost , reduce maintenance costs, and avoid air contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

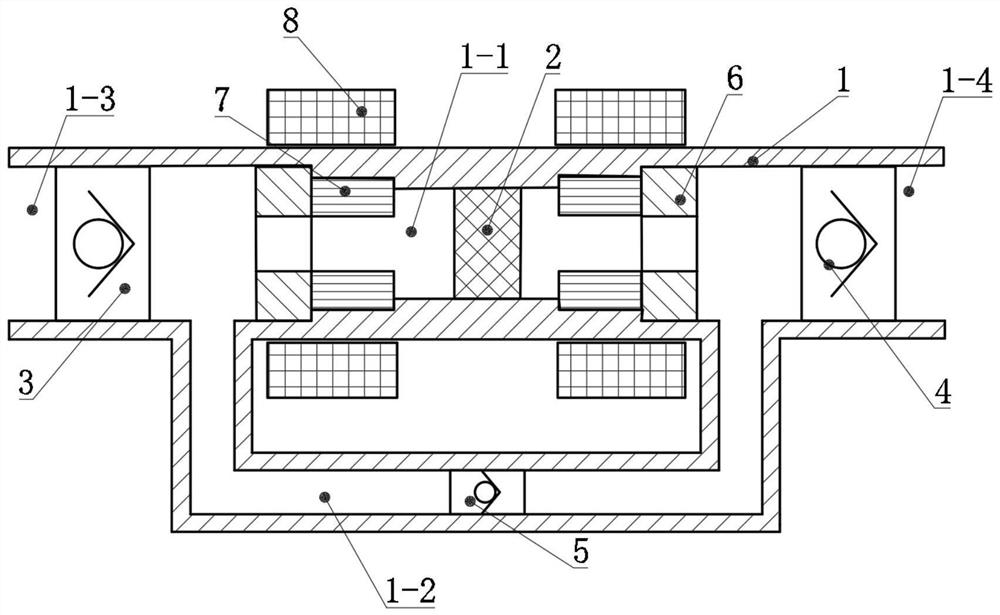

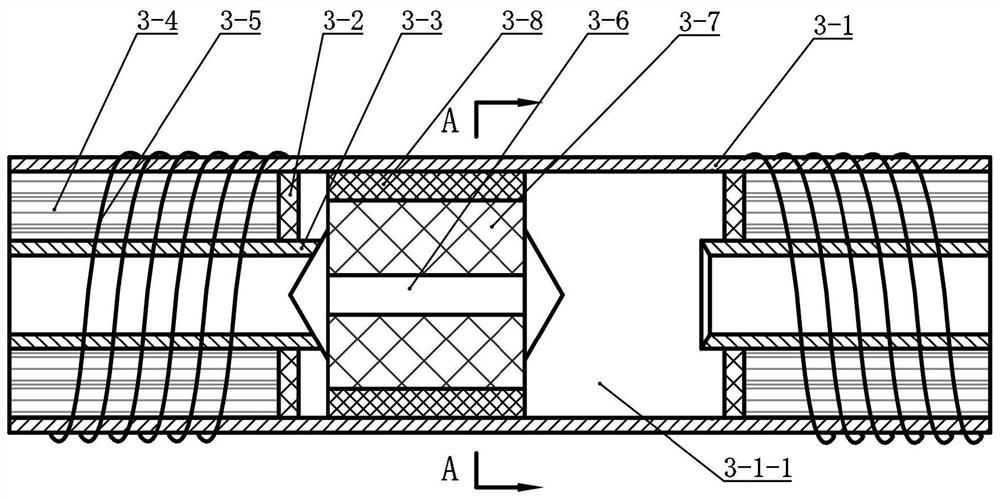

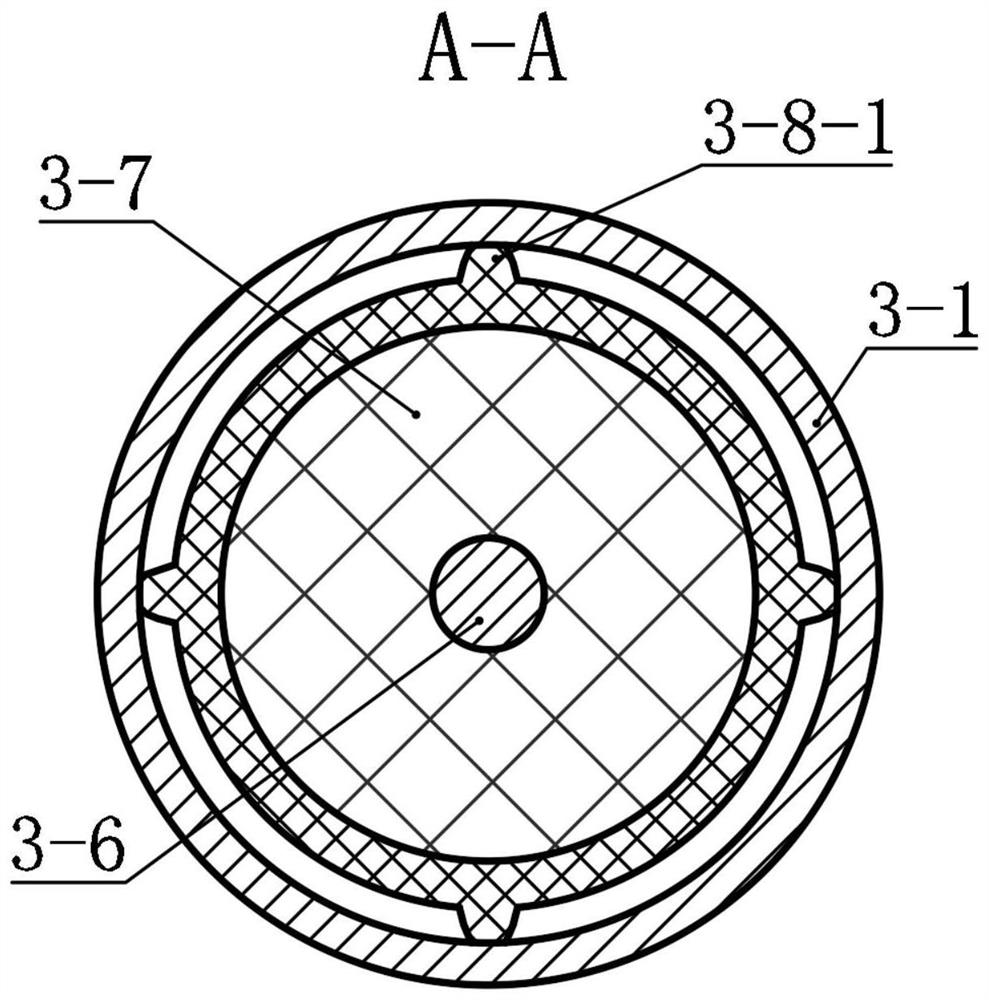

[0034] Such as figure 1 As shown, an electromagnetic two-way metering pump includes a pump casing 1, a pump liquid piston 2, a first variable check valve 3, a second variable check valve 4, a third variable check valve 5, and a piston drive components and control circuits. The pump casing 1 is provided with a piston sliding chamber 1-1, a pump liquid flow channel 1-2, a first interface chamber 1-3 and a second interface chamber 1-4. Both ends of the piston sliding chamber 1-1 communicate with the first interface chamber 1-3 and the second interface chamber 1-4 respectively. The two ends of the pump liquid channel 1-2 communicate with the first interface cavity 1-3 and the second interface cavity 1-4 respectively.

[0035]The piston sliding cavity 1-1 is in the shape of a symmetrical stepped hole. The pump liquid piston 2 is arranged in the middle part of the piston slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com