Tubular gas condensing boiler and system

A technology for condensing boilers and gas, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of increasing fault points, complicated waterways, and increasing side resistance of flue gas, so as to save heating natural gas and increase heat transfer coefficient , the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

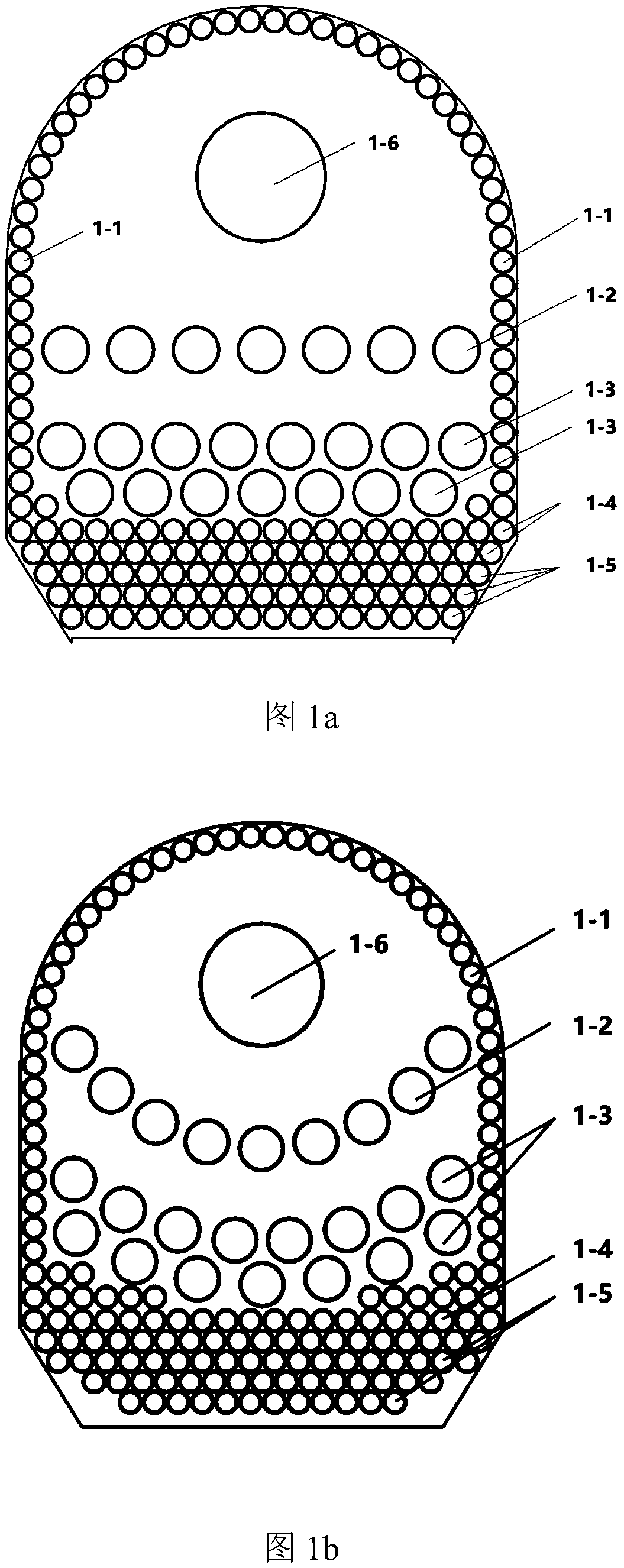

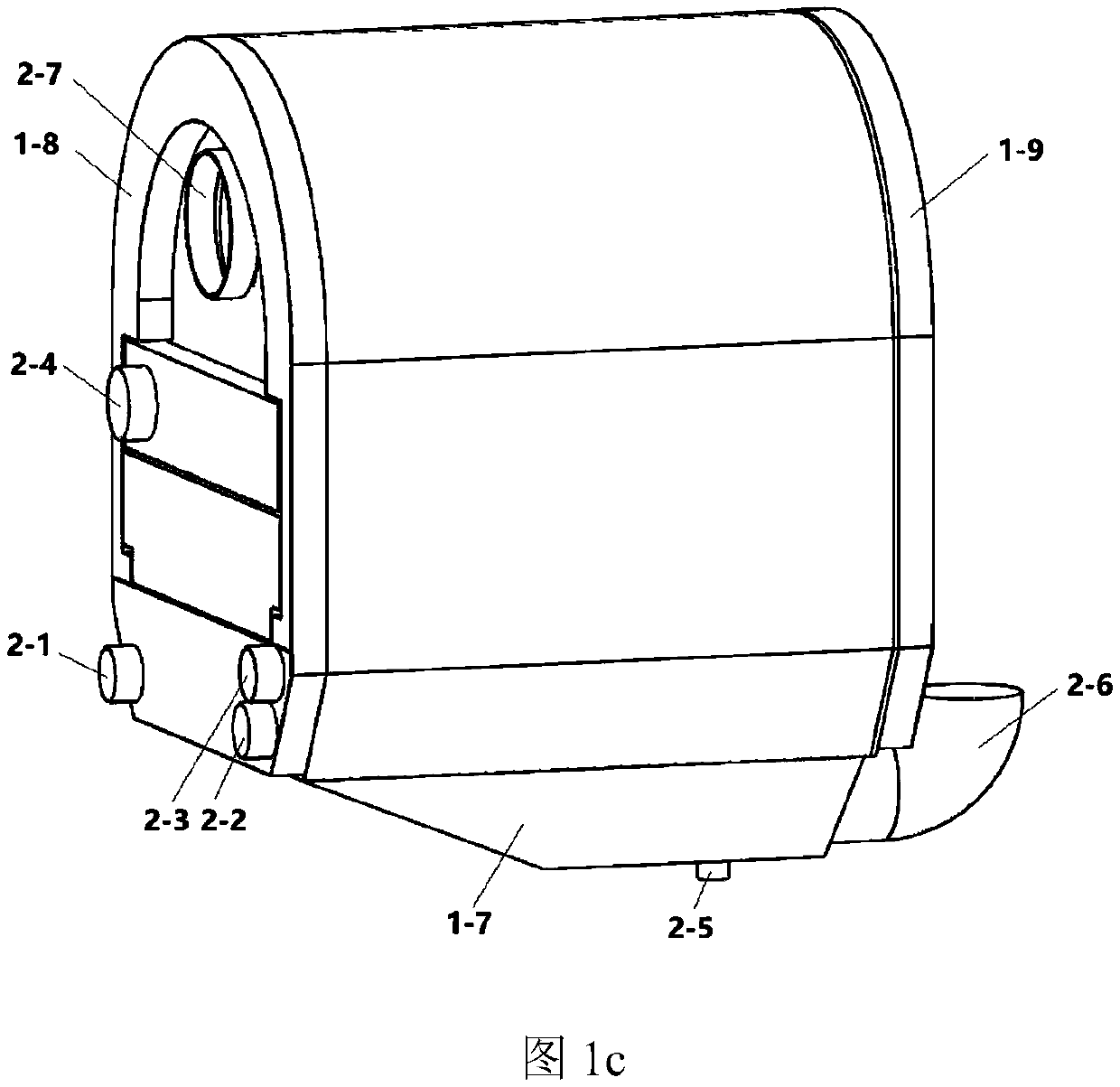

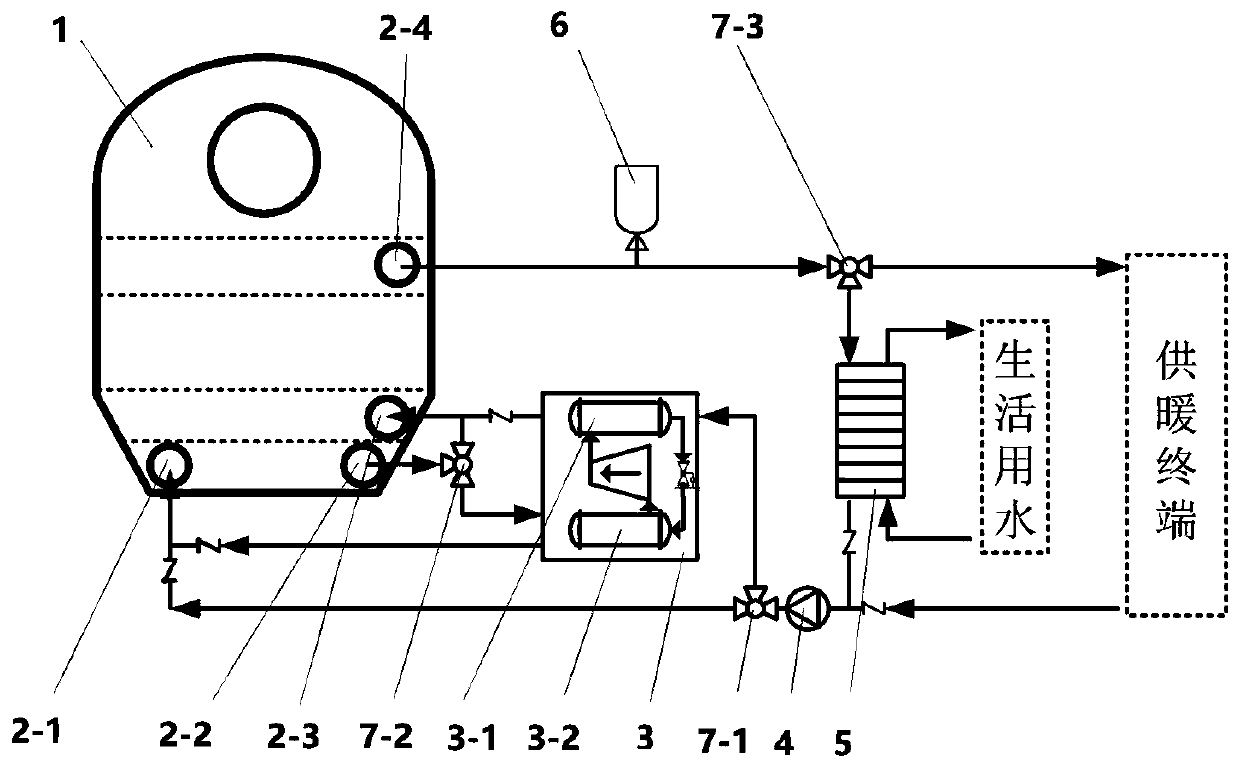

[0034] like figure 1 middle Figure 1a , Figure 1b and figure 1 As shown in c, the present invention is a tubular gas-fired condensing boiler. The boiler body consists of a circular tube water wall 1-1, a radiation cooling section 1-2, a convective cooling section 1-3, a deep cooling section 1-4, and a deep condensation section 1. -5. Composed of fully premixed burners 1-6, dew bearing plates 1-7, inlet and outlet side shells 1-8, turning side shells 1-9, etc. The material can be austenitic stainless steel 304L, 316L, etc., ferritic stainless steel 430, 434, etc., extruded aluminum 6000 series, etc. The high-temperature flue gas generated after the ignition of the fully premixed burner 1-6 scours the circular tube water wall 1-1 and the radiation cooling section 1-2, and then passes through the convection cooling section 1-3, the deep cooling se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com