Device and method for quickly coupling large-divergence-angle laser to single-mode optical fiber

A single-mode fiber and large divergence technology, which is applied in the field of devices that couple a large divergence angle laser to a single mode fiber and quickly couple a large divergence angle laser to a single mode fiber. Advanced problems, to achieve the effect of facilitating large-scale industrialization and automation, saving equipment costs, and improving coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

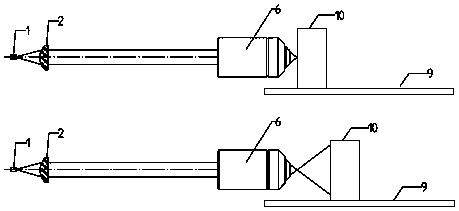

[0040] like Figure 1 to Figure 7 As shown, the present invention will be described in more detail below with reference to the accompanying drawings.

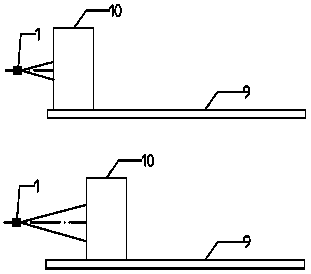

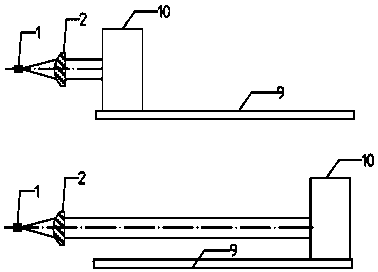

[0041] like figure 1 A laser chip 1 to be coupled into an optical fiber is shown, the divergence angle of the laser chip is 2θ, and the dotted line in the figure represents the optical axis.

[0042] A linear guide 9 is arranged on the five-axis adjustment platform, and a beam quality analyzer 10 that can move along the linear guide 9 is arranged on the linear guide 9 . Through the cooperation of the five-axis adjustment platform, the linear guide 9 and the beam quality analyzer 10, the laser chip 1, the collimator 2, the beam splitting prism 3, and the corner prism 4 , The industrial camera 5 , the coupling objective lens 6 and the optical fiber circulator 7 are adjusted in position. The specific operation is as follows.

[0043] like figure 1 As shown, the laser chip 1 is fixed on the five-axis adjustment platform. Turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com