Back-lighting-type near-infrared pixel unit and manufacturing method thereof

A pixel unit and near-infrared technology, applied in the field of image sensors, can solve problems such as the inability of lithography machines to penetrate effectively, the inability to realize the alignment of silicon wafer backside graphics and front-side transistors, and affect the performance of near-infrared pixel units, so as to improve epitaxy. Layer thickness, effect of increasing photosensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solution and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

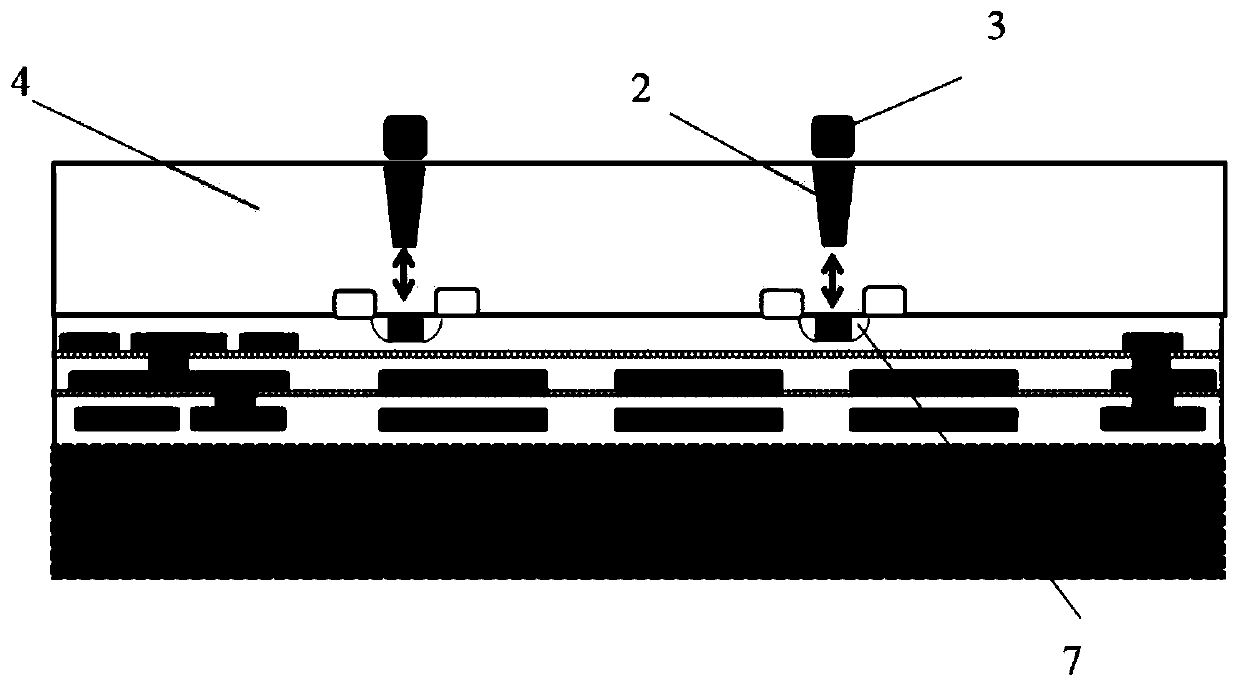

[0034] as attached figure 1 As shown, since the thickness of the epitaxial layer 4 required in the near-infrared pixel unit is tens or even hundreds of microns, and under this thickness, the photolithography machine cannot isolate the front transistor 7 at the bottom of the silicon layer from the back trench at the top of the silicon layer 2 and the back metal isolation 3 are aligned, thereby affecting the normal operation of the near-infrared pixel unit.

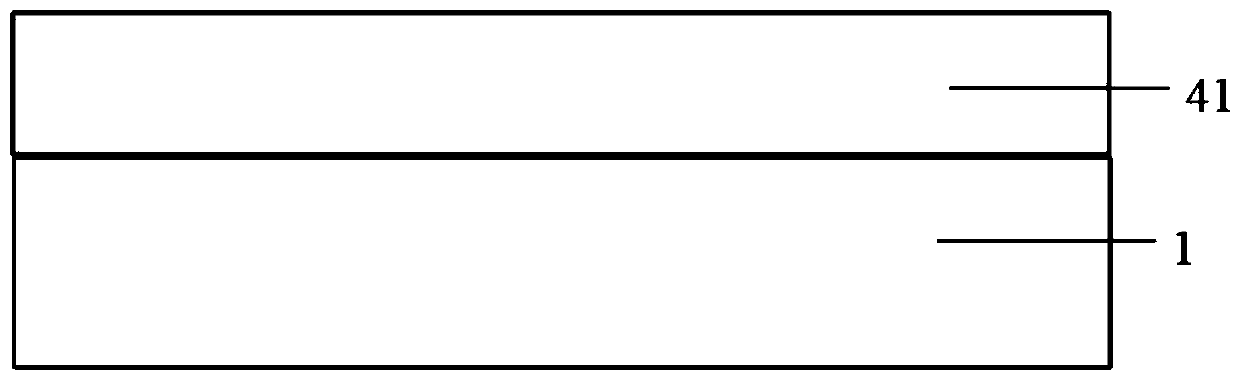

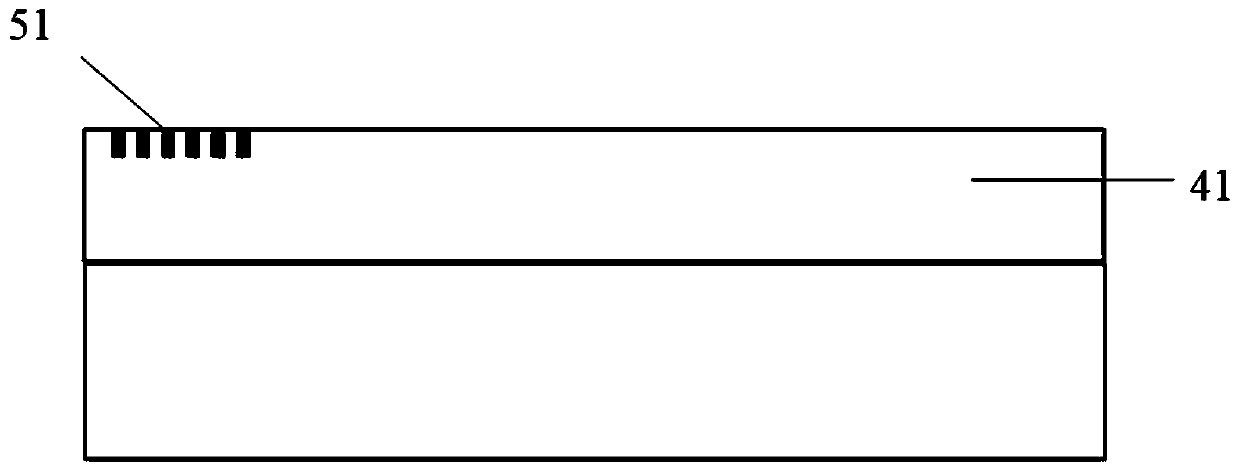

[0035] as attached Figure 9 As shown, a back-illuminated near-infrared pixel unit provided by the present invention includes a carrier 8, a front device 11, an epitaxial layer, and a rear device 12, wherein the epitaxial layer includes a first epitaxial layer 41, a seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com