Solution and straightening method for titanium alloy boards

A technology for titanium alloys and plates, applied in the field of solid solution straightening of titanium alloy plates, can solve problems such as wave bending and edge wave bending of plates, and achieve the effect of less equipment investment, large margin and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

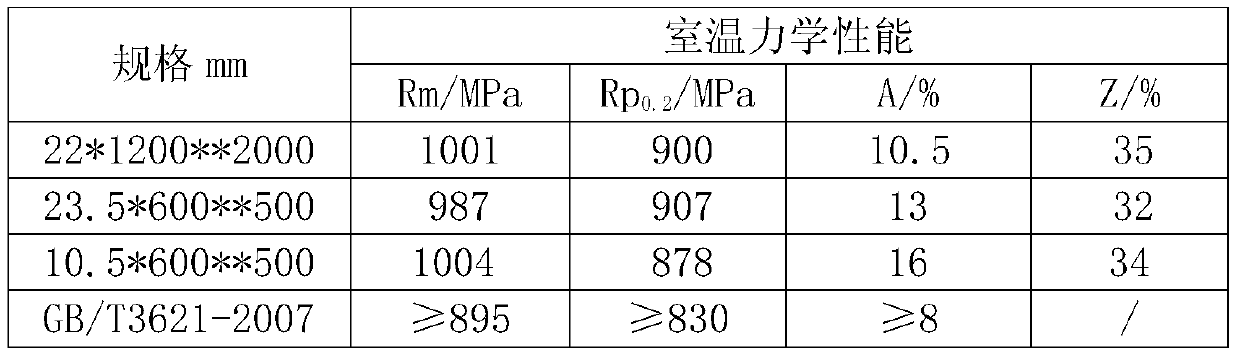

[0035] Produce TC4 hot-rolled sheets with a thickness of 10.5-23.5*200-1200*500-2000mm.

[0036] ①The size of the lower substrate is 110*1300*3000mm, the size of the upper substrate is 200*1300*3000mm, the surface of the upper and lower substrates is milled, the roughness is 3.2um, and the unevenness is 2mm / M.

[0037] ②On the lower base plate, place 1 sheet of 22*1200*2000mm horizontally in the first layer from bottom to top, place 4 sheets of 23.5*600*500mm horizontally in the second layer of splicing, and horizontally place the third layer of splicing Place 4 plates of 10.5*600*500mmmm, the total thickness of the plates is 56mm, and the thickness of the lower substrate + the thickness of the plates is 166mm in total.

[0038] ③Place the lower substrate and the stacked plates horizontally in the heating furnace as a whole, and the upper substrate is also heated with the furnace. According to the rate of 1.5mm / min, the temperature is rapidly raised to 880°C for 5 hours for so...

Embodiment 2

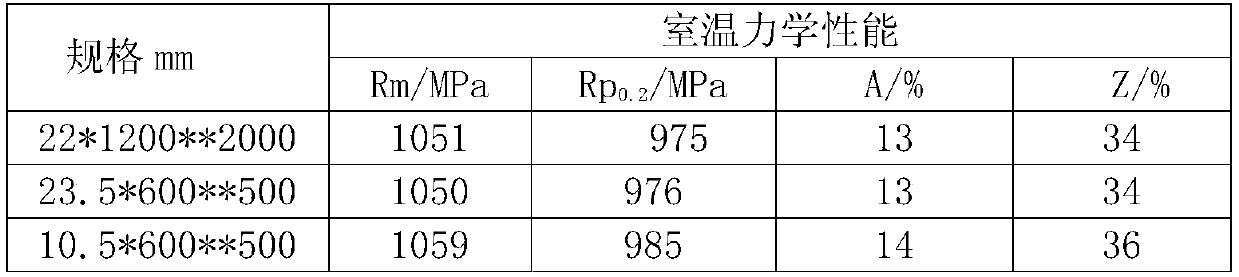

[0048] Produce new titanium alloy hot-rolled plates with a thickness of 9.5-22.5*200-1200*500-2000mm.

[0049] ①The size of the lower substrate is 110*1300*3000mm, the size of the upper substrate is 200*1300*3000mm, the surface of the upper and lower substrates is milled, the roughness is 3.2um, and the unevenness is 2mm / M.

[0050] ②On the lower substrate, place 4 sheets of 22.5*600*500mm horizontally on the first layer of splicing from bottom to top, place 2 sheets of 10*1200*2000mm horizontally on the second layer in a stacked manner, and splice the third layer The method is to place 8 sheets of 9.5*600*500mmmm boards horizontally, the total thickness of the boards is 61.5mm, and the thickness of the lower substrate + the thickness of the boards is 161.5mm in total.

[0051] ③ Place the lower substrate and the stacked plates horizontally in the heating furnace as a whole, and the upper substrate is also heated with the furnace. According to the rate of 1.5mm / min, the process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com