Transverse column architecture protective cover for numerical control machine tool

A technology of CNC machine tools and protective covers, applied in the direction of maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc., can solve the problem of contamination of the horizontal column, and achieve the effect of convenient replacement or cleaning, simple replacement and reliable principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

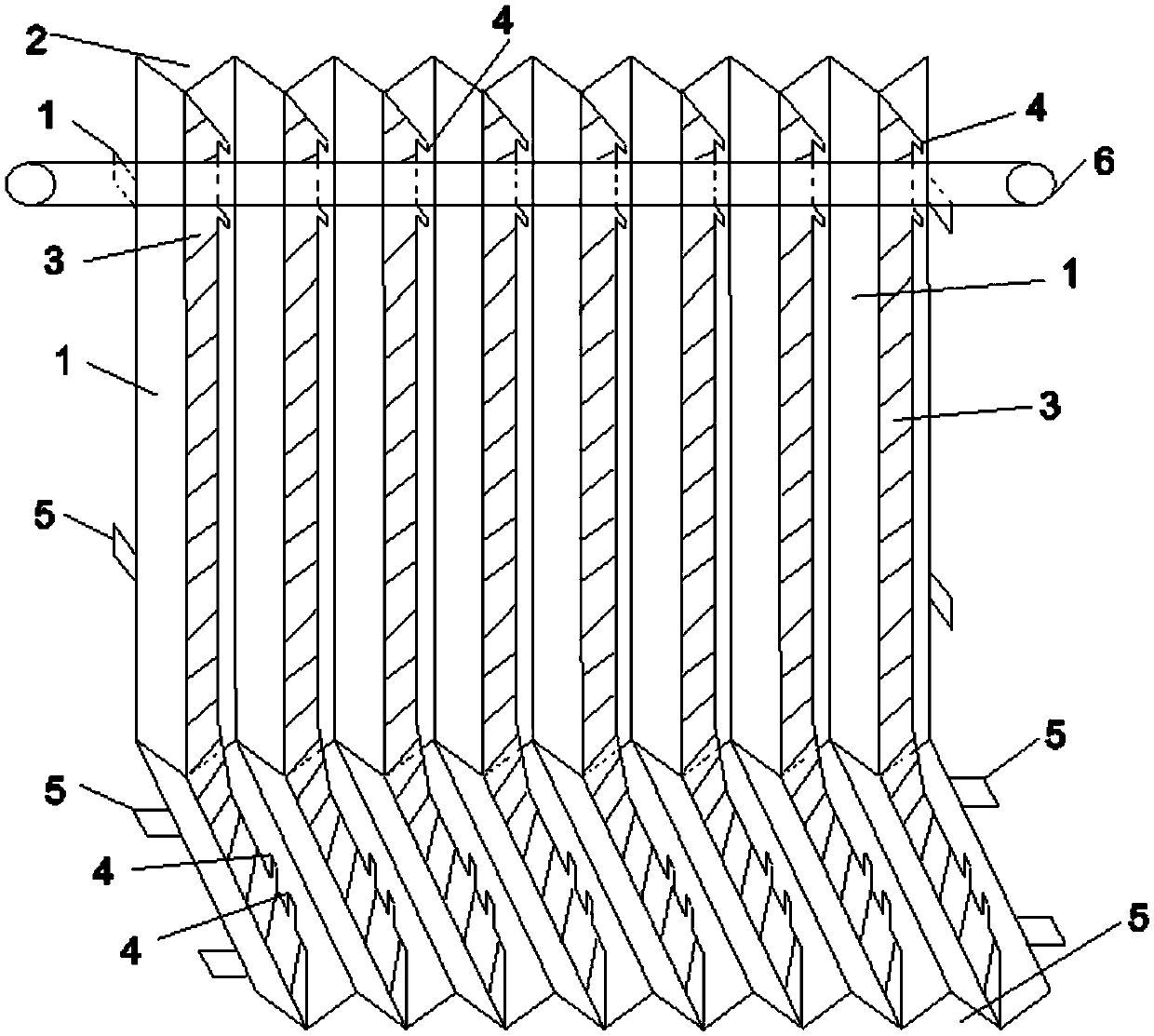

[0012] The main structure of a protective cover for a horizontal column structure of a CNC machine tool involved in this embodiment includes a hard layer 1, a bending opening 2, a soft iron sheet 3, a horizontal column gripper 4, a fixer 5 and a horizontal column tube 6; L-shaped The hard layer 1 of the structure is bent and wrapped on the front and bottom surfaces of the exposed horizontal column structure (not shown in the drawings). The length of the hard layer 1 after stretching is 1.1-2 times the length of the horizontal column, so that the horizontal column can push When the faucet moves laterally to the maximum distance, the hard layer 1 can maintain the elastic space to prevent it from breaking; The soft iron sheet 3 of L-shaped structure is connected with the hard layer 1 at the bending seam corresponding to the bending opening 2, so as to support and enhance the strength of the protective cover; the vertical surface and the horizontal surface of the soft patch 3 are u...

Embodiment 2

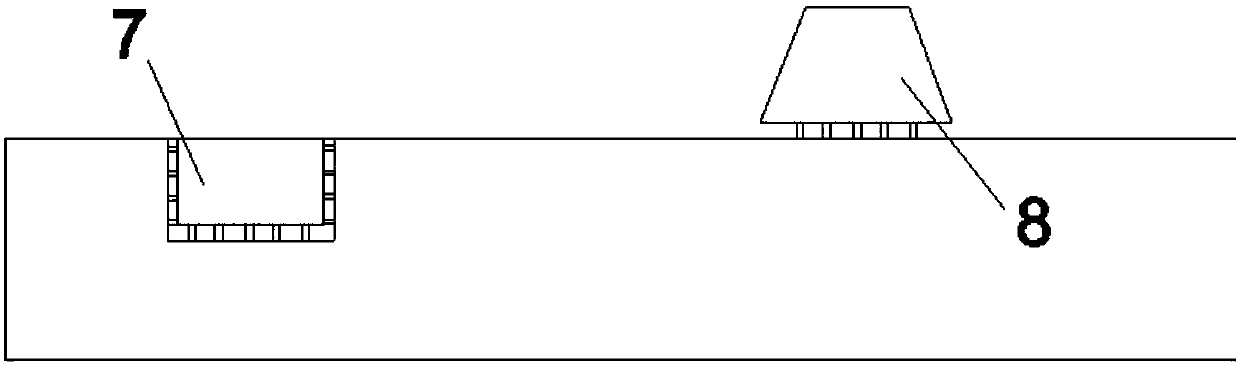

[0017] The main structure of a protective cover for a horizontal column structure of a CNC machine tool involved in this embodiment includes a hard layer 1, a bending opening 2, a soft iron sheet 3, a horizontal column gripper 4, a fixer 5, a horizontal column tube 6 and a virtual joint Groove 7; the hard layer 1 of the L-shaped structure is bent and wrapped on the front and bottom of the exposed horizontal column. The length of the hard layer 1 after stretching is 1.1-2 times the length of the horizontal column, so that the horizontal column can push the faucet to move laterally When the maximum distance is reached, the hard layer 1 can maintain an elastic space to prevent it from breaking; the hard layer 1 is provided with a bending opening 2 at a certain distance to facilitate left and right elongation and shortening, and the inner side of the corresponding seam of the bending opening 2 is provided with an L-shaped structure The soft iron sheet 3 is connected with the hard l...

Embodiment 3

[0022] The main structure of a protective cover for a horizontal column structure of a CNC machine tool involved in this embodiment includes a hard layer 1, a bending opening 2, a soft iron sheet 3, a horizontal column gripper 4, a fixer 5, a horizontal column tube 6 and a virtual joint Protrusion 8; the hard layer 1 of the L-shaped structure is bent and wrapped on the front and bottom of the exposed horizontal column, and the length of the hard layer 1 after stretching is 1.1-2 times the length of the horizontal column, so that the horizontal column can push the faucet to move laterally When the maximum distance is reached, the hard layer 1 can maintain an elastic space to prevent it from breaking; the hard layer 1 is provided with a bending opening 2 at a certain distance to facilitate left and right elongation and shortening, and the inner side of the corresponding seam of the bending opening 2 is provided with an L-shaped structure The soft iron sheet 3 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com