Coated type metal workpiece surface strengthening grinding processing method and device

A technology of surface strengthening and grinding, which is applied in the direction of metal processing equipment, abrasives, manufacturing tools, etc., can solve the problems of reducing the impact strength of the processing area, polluting the environment, and reducing residual compressive stress, so as to improve the overall quality, avoid air pollution, The effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order for those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

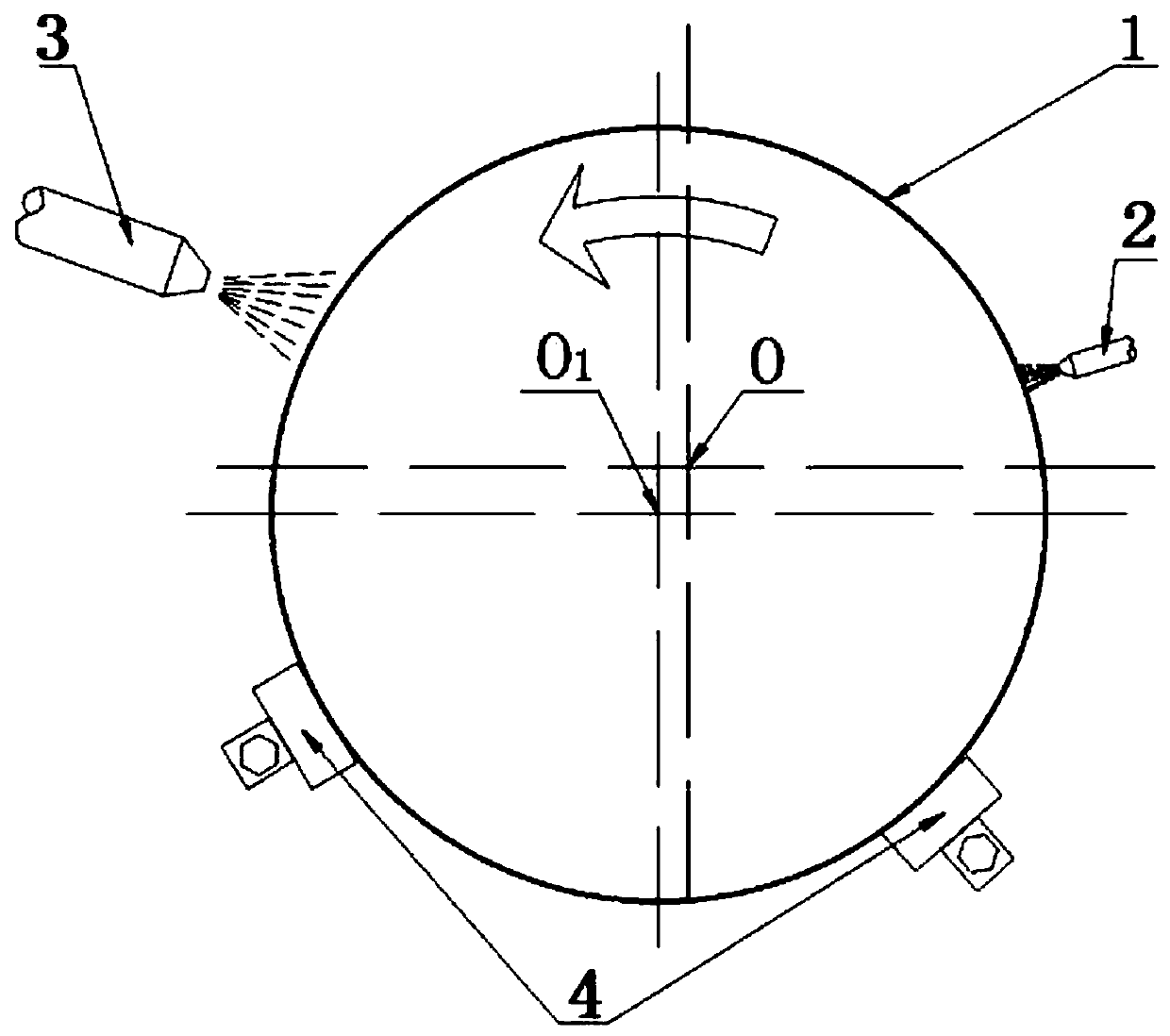

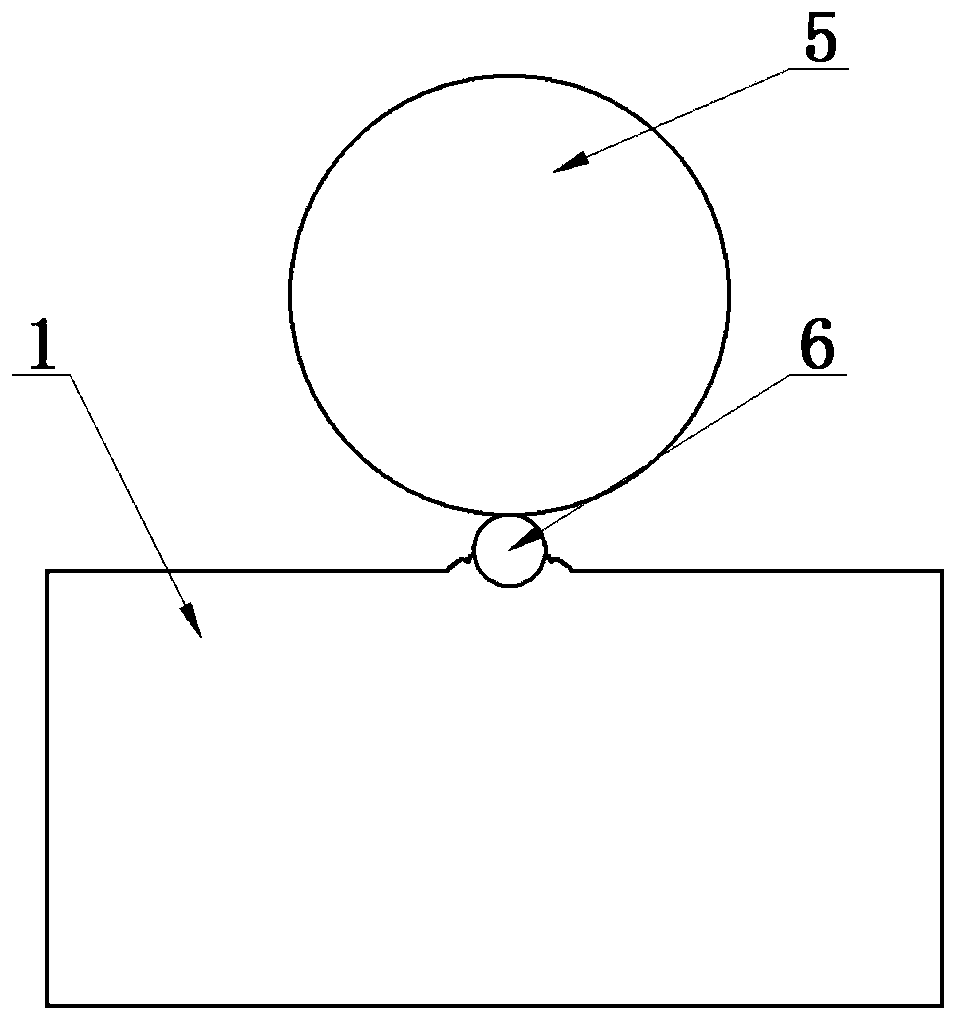

[0037] seefigure 1 , this is the graffiti-type metal workpiece surface strengthening grinding processing equipment in the embodiment, including a rotary clamping device for clamping the workpiece 1, and a mixed graffiti device for uniformly scribbling mixed abrasives on the processed surface of the workpiece 1 And a high-pressure injection device for spraying high-speed steel balls 5 on the processed surface of the workpiece 1, the mixed abrasive is a semi-fluid mixture formed by mixing grinding liquid and grinding powder.

[0038] Wherein, the rotary clamping device includes an electromagnetic centerless clamp, a rotary drive mechanism for driving the electromagnetic centerless cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com