Hybrid reinforced grinding method for bearing machining

A grinding method and bearing processing technology, applied in used abrasive processing devices, metal processing equipment, abrasives, etc., can solve problems such as affecting processing accuracy, reducing impact strength in processing areas, and reducing fatigue resistance, achieving uniform effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order for those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

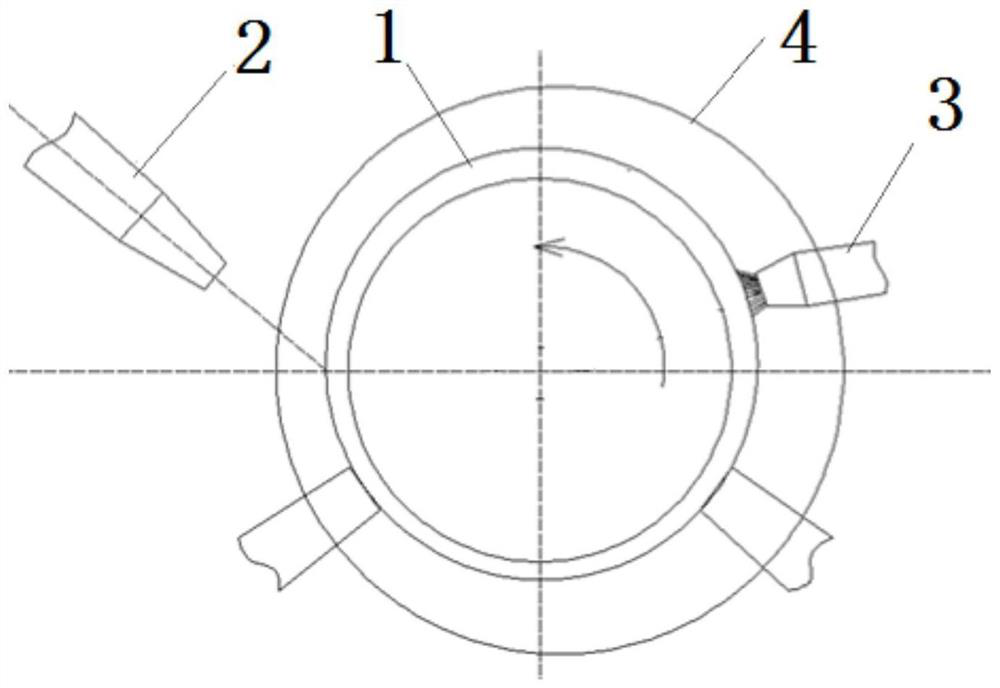

[0031] see figure 1 , the hybrid intensified grinding method for bearing processing in this embodiment includes the following steps:

[0032] (1) Clamp the bearing to be processed (such as the inner ring of the bearing) on the electromagnetic centerless fixture, and adjust the current and speed of the electromagnetic centerless fixture so that the magnetic attraction generated by the electromagnetic centerless fixture is approximately equal to the bearing to be processed gravity.

[0033] (2) Adjust the position of the high-speed nozzle so that it is aligned with the processing surface of the bearing, and make the angle between the centerline of the high-speed nozzle and the tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com