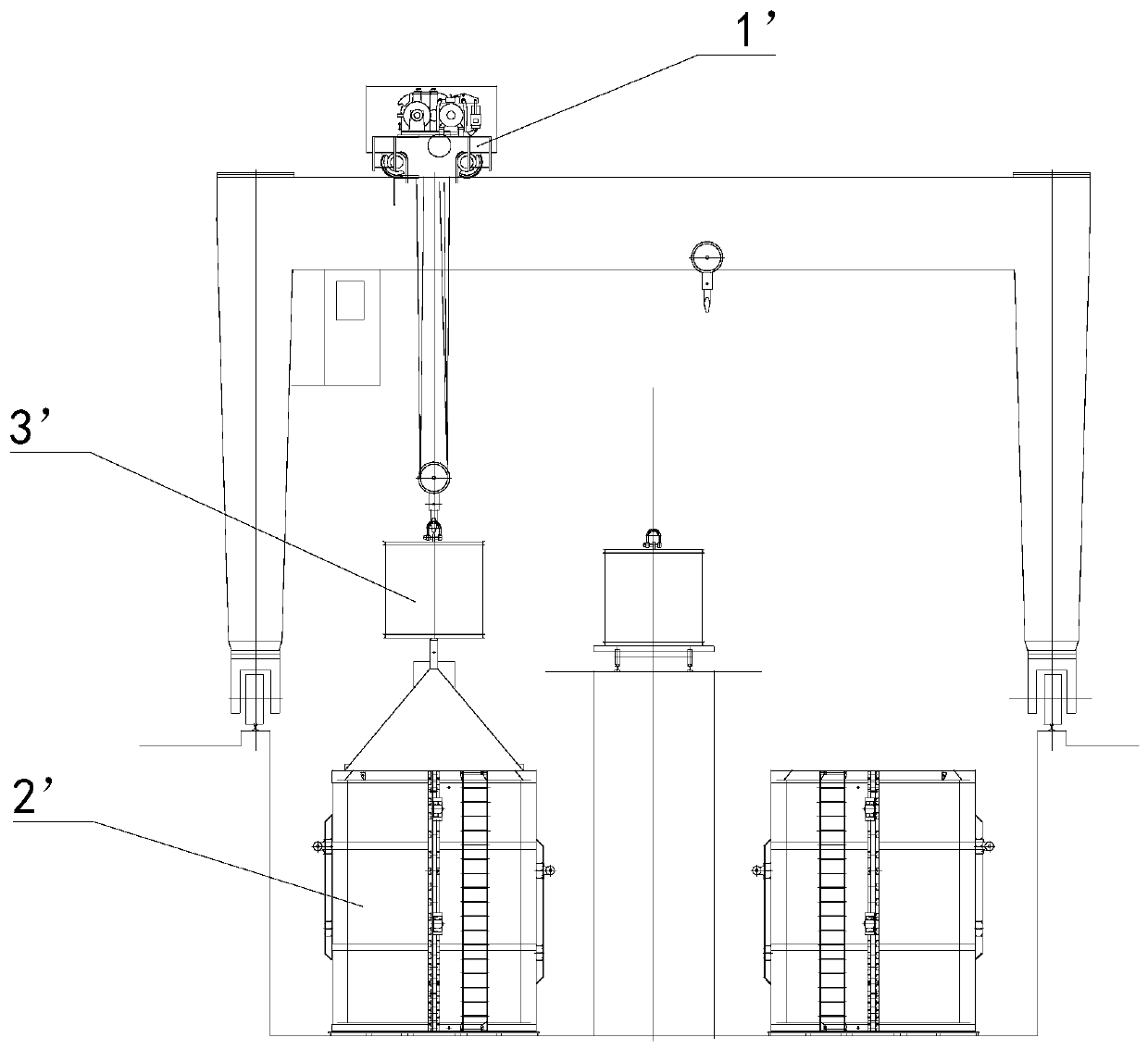

Feed car and pipeline pouring system

A feeding truck and pipeline technology, applied in the field of feeding truck and pipeline pouring system, can solve the problems of high labor intensity, high safety risk, low work efficiency, etc., and achieve the effect of simplifying operation, improving production efficiency, and avoiding operation risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

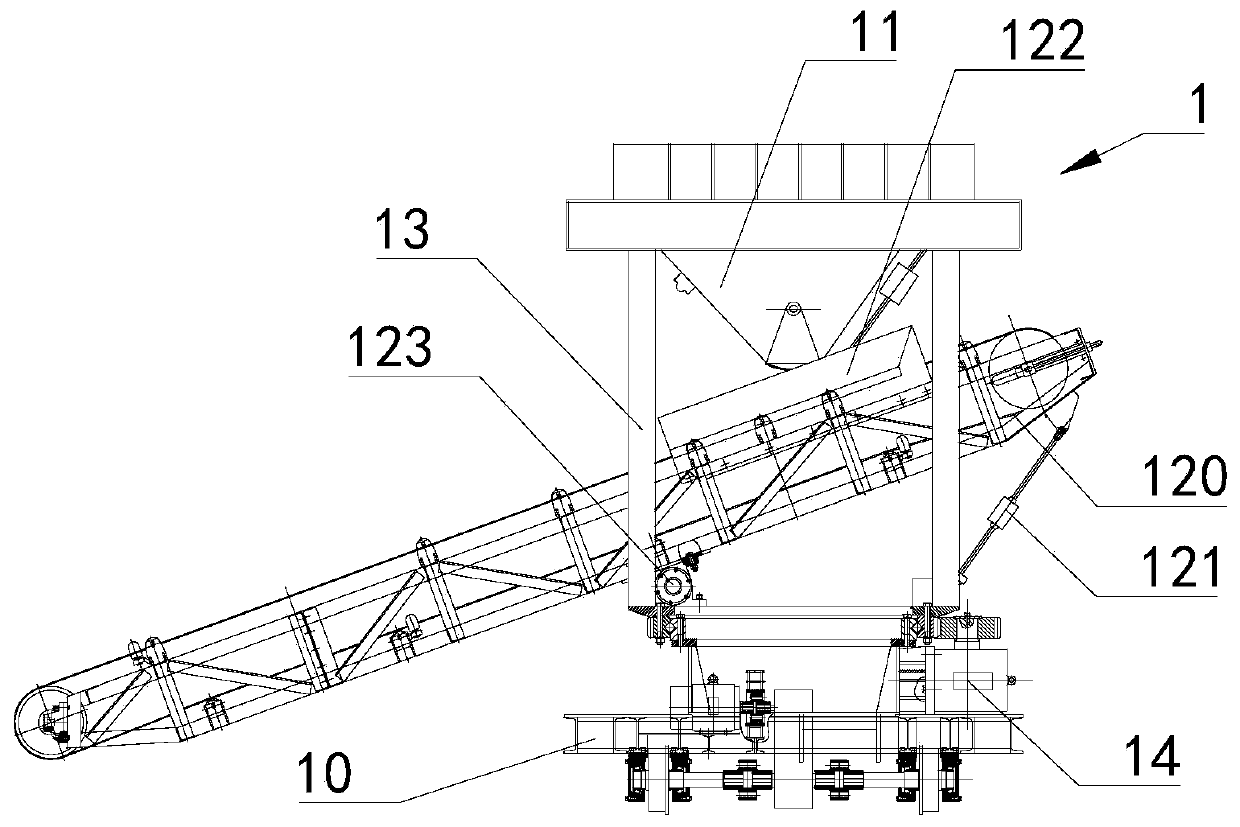

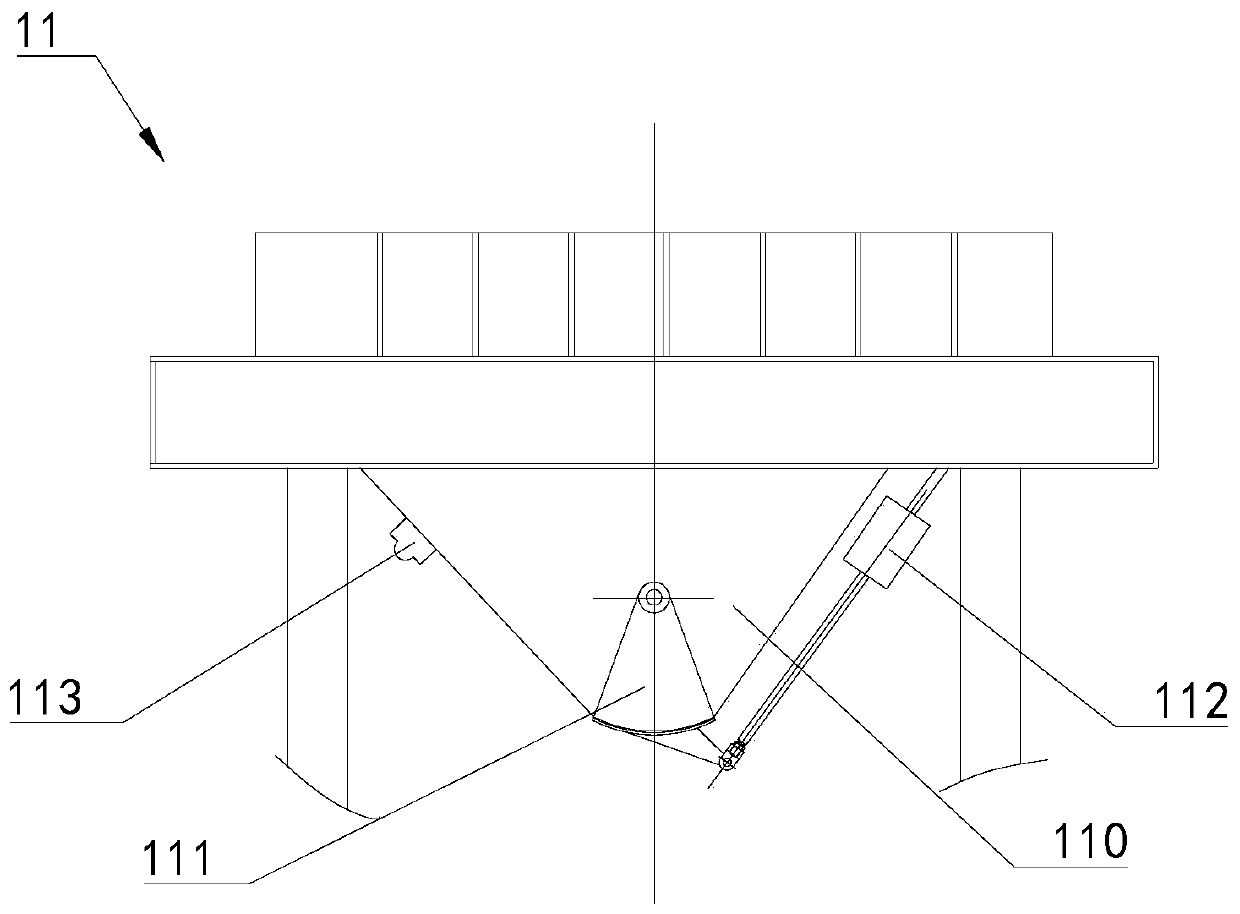

[0050] see Figure 2 to Figure 4 As shown, the present embodiment provides a feeding car; figure 2 The schematic structural view of the feeding car provided in this embodiment, the structure of the feeding car is simply shown in the figure; image 3 for figure 2 The left side view of the feeding cart is provided, the conveyor belt is omitted for clarity of the structure of the pivot shaft; Figure 4 The structural schematic diagram of the hopper assembly of the feeding cart provided in this embodiment.

[0051] The feeding cart provided in this embodiment is used in a pipeline pouring system. The feeding truck can transport the concrete material mixed by the mixing station and pour it into the pipeline casting mold.

[0052] see Figure 2 to Figure 4 and combine Figure 5 and Figure 6 As shown, the feeding cart 1 provided in this embodiment includes a car body assembly 10 , a hopper assembly 11 , a conveyor belt assembly 12 and a driving assembly 14 . The vehicle bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com