Green mulching film special for peanuts and production method of green mulching film special for peanuts

A green, plastic film technology, applied in the fields of botanical equipment and methods, application, plant protection, etc., to achieve the effects of scientific and reasonable preparation methods, solving easy burns, and improving herbicidal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

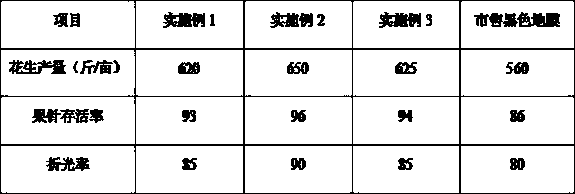

Examples

Embodiment 1

[0030] A special green mulch film for peanuts is made from the following raw materials by weight: linear polyethylene 83%; metallocene 9%; special filler 8%; wherein, the special filler is made from the following raw materials by weight: phthalocyanine blue Pigment 12%; light yellow pigment 13%; polyethylene wax 6%; polyethylene 60%; titanium dioxide 9%.

[0031] A preparation method of the above-mentioned special green mulch film for peanuts, comprising the following steps:

[0032] (1) Prepare special fillers, add phthalocyanine blue pigment and light yellow pigment to a high-speed mixer with a speed of 1900N / min and stir for 5 minutes, then add polyethylene wax, polyethylene and titanium dioxide to the above-mentioned high-speed mixer and continue to stir for 5 minutes , to obtain the mixed material S1; the mixed material S1 is added to the twin-screw extruder for granulation to obtain a special filler; wherein, the processing temperature of the extrusion zone of the twin-s...

Embodiment 2

[0036] A special green mulch film for peanuts is made from the following raw materials by weight: linear polyethylene 83%; metallocene 10%; special filler 7%; wherein, the special filler is made from the following raw materials by weight: phthalocyanine blue Pigment 15%; light yellow pigment 15%; polyethylene wax 5%; polyethylene 55%; titanium dioxide 10%.

[0037] A preparation method of the above-mentioned special green mulch film for peanuts, comprising the following steps:

[0038] (1) Prepare special fillers, add phthalocyanine blue pigment and light yellow pigment to a high-speed mixer with a speed of 1900N / min and stir for 5 minutes, then add polyethylene wax, polyethylene and titanium dioxide to the above-mentioned high-speed mixer and continue to stir for 5 minutes , to obtain the mixed material S1; the mixed material S1 is added to the twin-screw extruder for granulation to obtain a special filler; wherein, the processing temperature in the extrusion zone of the twin...

Embodiment 3

[0042] A special green mulch film for peanuts is made of the following mass fractions: linear polyethylene 85%; metallocene 9%; special filler 6%; wherein, the special filler is made of the following raw materials by weight: phthalocyanine blue pigment 17%; light yellow pigment 13%; polyethylene wax 5%; polyethylene 57%; titanium dioxide 8%.

[0043] A preparation method of the above-mentioned special green mulch film for peanuts, comprising the following steps:

[0044] (1) Prepare special fillers, add phthalocyanine blue pigment and light yellow pigment to a high-speed mixer with a speed of 1900N / min and stir for 5 minutes, then add polyethylene wax, polyethylene and titanium dioxide to the above-mentioned high-speed mixer and continue to stir for 5 minutes , to obtain the mixed material S1; the mixed material S1 is added to the twin-screw extruder for granulation to obtain a special filler; wherein, the processing temperature in the extrusion zone of the twin-screw extruder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Temperature resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com