Assembly-type limiting reinforced steel wood frosted sleeve combined node

A combined node and assembly technology, applied in buildings, pillars, piers, etc., can solve the problems of complex detection methods, poor seismic performance, and high labor costs, and achieve the effects of good mechanical performance, simple processing and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

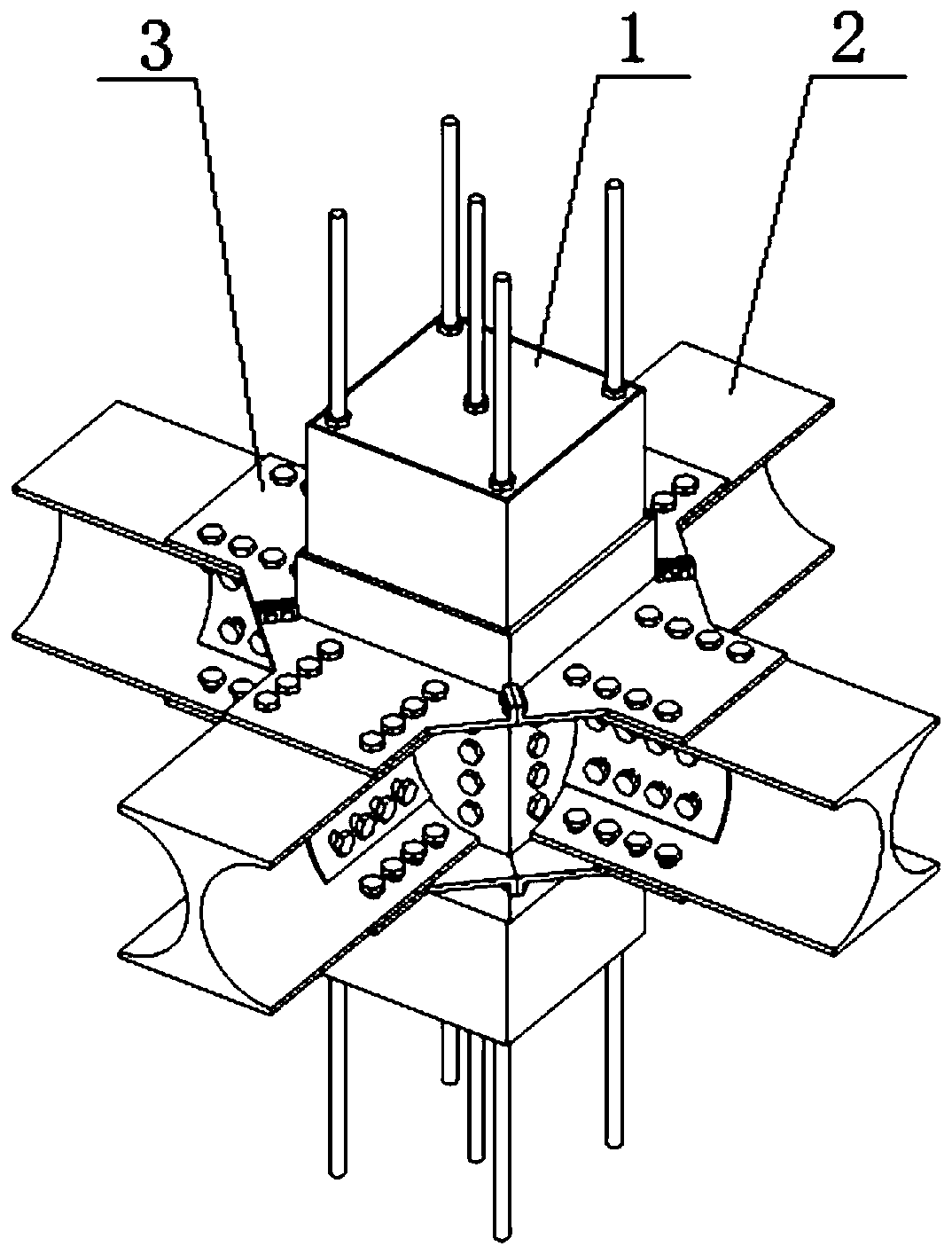

[0045] Such asfigure 1 As shown, the present invention is an assembly-type limit-reinforced steel-wood frosted sleeve combined node, including a square center column 1, an X-shaped wooden beam 2, and a beam-column connection assembly 3, and the beam-column connection assembly 3 is fixedly sleeved on the square center column 1, the X-shaped wooden beam 2 is located on the outer side of the beam-column connection component 3, and is fixedly connected with the beam-column connection component 3, so the beam-column connection component 3 realizes the connection between the square center column 1 and the X-shaped wooden beam 2 .

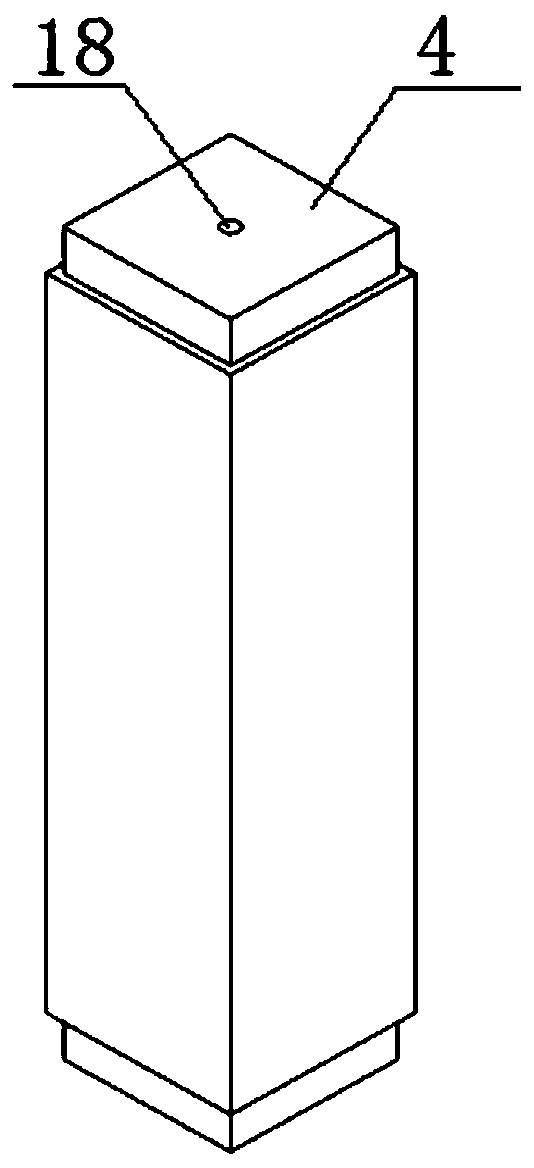

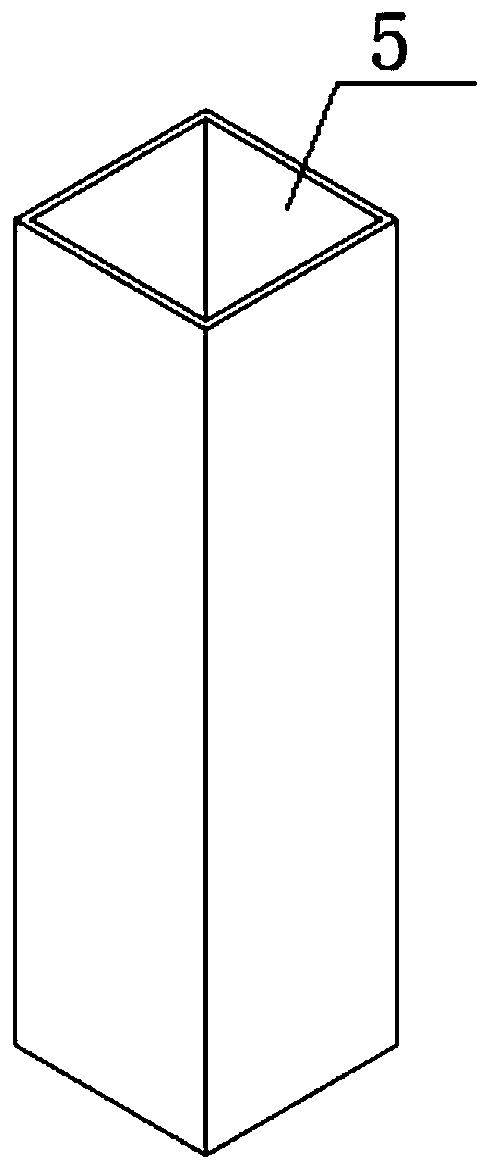

[0046] As shown in FIGS. 2 to 6 , the square center column 1 includes a frosted wooden column 4 , a frosted steel sleeve 5 , a frosted wood sleeve shell 6 , a FRP fiber reinforced composite material layer 7 and a center column frosted steel cover 8 . Such as Figure 2(a) to Figure 2(c) As shown, the frosted wooden column 4 is a cuboid, and the center of ...

Embodiment 2

[0060] The difference from Embodiment 1 is that the frosted wood sleeve shell 6 in this embodiment is a whole. Such as Figure 10(a) to Figure 10(b) shown.

[0061] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com