Aerostatic Bearing Based on Passive Vibration and Energy Dissipation Based on Additional Mass Motion

A technology of additional mass and gas static pressure, applied in the direction of air cushion bearings, bearings, shafts and bearings, etc., can solve the problems of small bearing capacity, increase the internal air cavity of the air bearing, and increase the risk of nonlinear instability of fluid motion, etc., to achieve The effect of large bearing capacity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

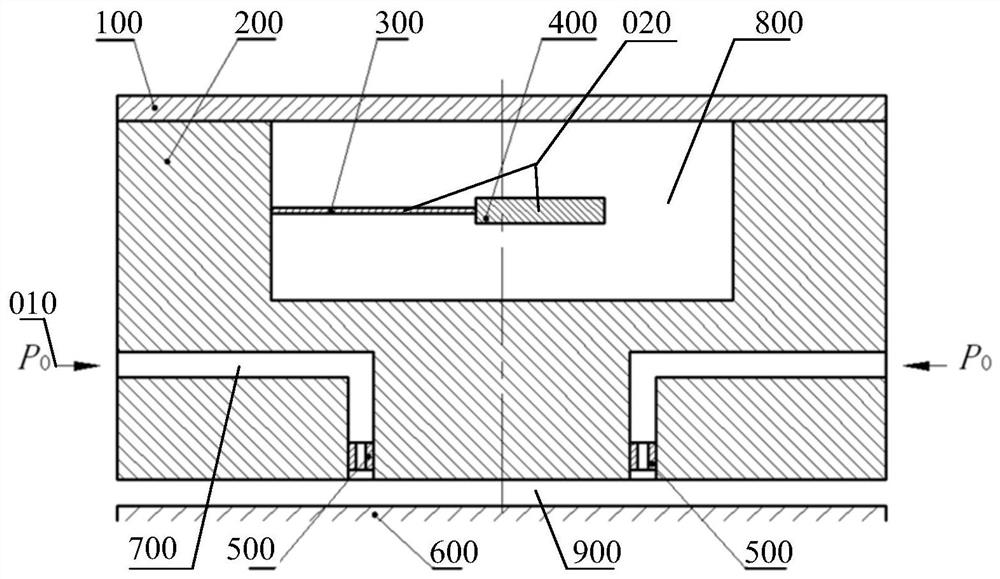

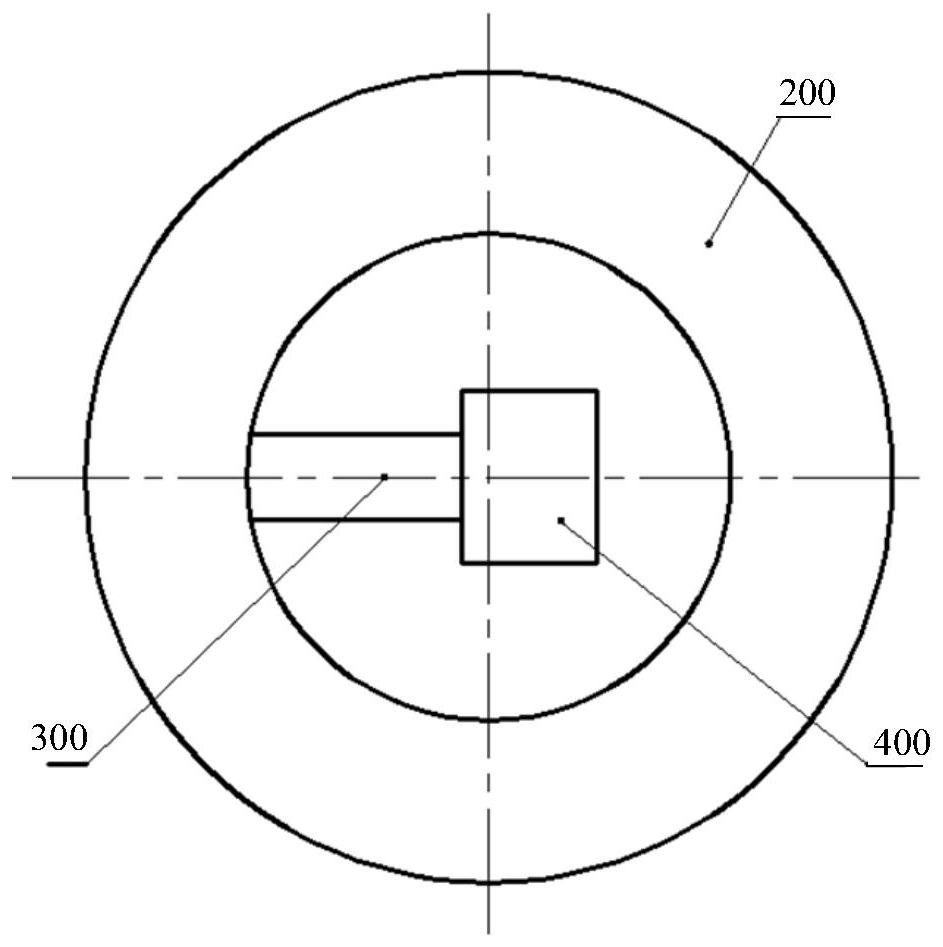

[0048] Gas static pressure bearings based on passive vibration and energy consumption based on the motion of additional mass, such as figure 1 and figure 2 As shown, it is composed of the bearing body 200, the throttle plug 500 and the cladding plate 100. The compressed air 010 passes through the throttle plug 500 arranged in the bearing body 200 at P0 pressure and enters the gap between the bearing body 200 and the bearing corresponding surface 600 900, and form a thin air film, through which the suspension support of the bearing main body 200 is realized; a flexible thin plate 300 and an additional mass 400 are arranged on the inner wall of the upper cavity 800 of the bearing main body 200, and one side of the flexible thin plate 300 is tightly connected with the The bearing body 200 is fastened to the additional mass 400 on the other side; during the operation of the bearing, the additional mass 400 can move in a vertical direction relative to the bearing body 200 through ...

specific Embodiment approach 2

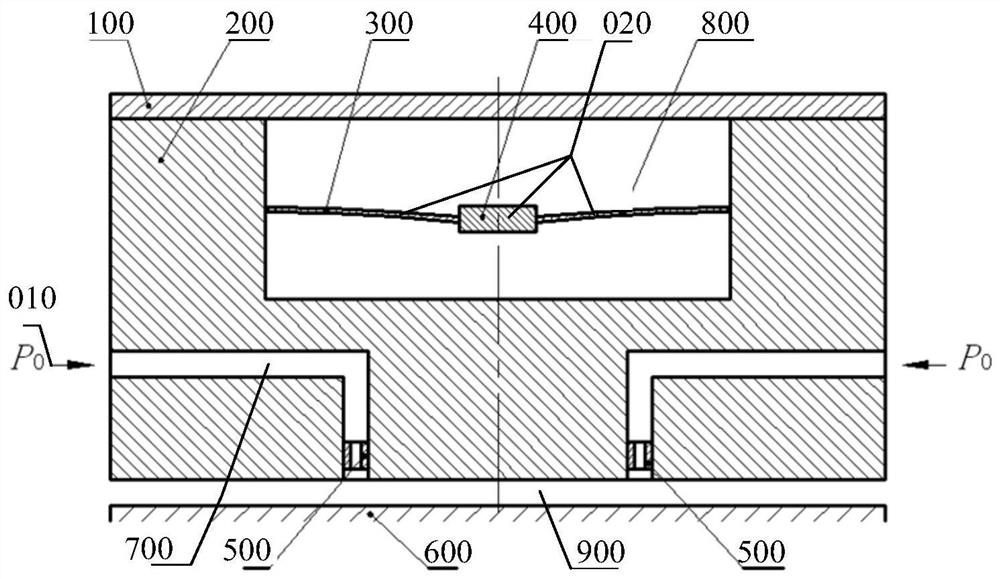

[0052] Gas static pressure bearings based on passive vibration and energy consumption based on the motion of additional mass, such as image 3 As shown, it is composed of the bearing body 200, the throttle plug 500 and the cladding plate 100. The compressed air 010 passes through the throttle plug 500 arranged in the bearing body 200 at P0 pressure and enters the gap between the bearing body 200 and the bearing corresponding surface 600 900, and a thin air film is formed, and the suspension support of the bearing body 200 is realized by the thin air film; two flexible thin plates 300 and an additional mass 400 are arranged on the inner wall of the upper cavity 800 of the bearing body 200, and the two flexible thin plates 300 are one One side is fastened to the bearing body 200, and the other side is fastened to the two sides of the additional mass 400. The two flexible thin plates 300 are symmetrical to the additional mass 400. During the operation of the bearing, the additiona...

specific Embodiment approach 3

[0054] Gas static pressure bearings based on passive vibration and energy consumption based on the motion of additional mass, such as Figure 4 As shown, it is composed of the bearing body 200, the throttle plug 500 and the cladding plate 100. The compressed air 010 passes through the throttle plug 500 arranged in the bearing body 200 at P0 pressure and enters the gap between the bearing body 200 and the bearing corresponding surface 600 , and a thin air film is formed, and the suspension support of the bearing body 200 is realized by the thin air film; a flexible spring 300 and an additional mass 400 are arranged at the bottom of the upper cavity 800 of the bearing body 200, and one side of the flexible spring 300 is tightly connected with the bearing body 200, and the other side is fastened to the additional mass 400; the additional mass 400 can move in a vertical direction relative to the bearing body 200 through the flexible spring 300; when the aerostatic bearing vibrates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com