Rotary machine field dynamic balance calculating and adjusting method based on Office software

A technology for on-site dynamic balancing and rotating machinery, applied in static/dynamic balance testing, testing of machine/structural components, instruments, etc., can solve the problems of complex calculation and implementation, inability to save at any time, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

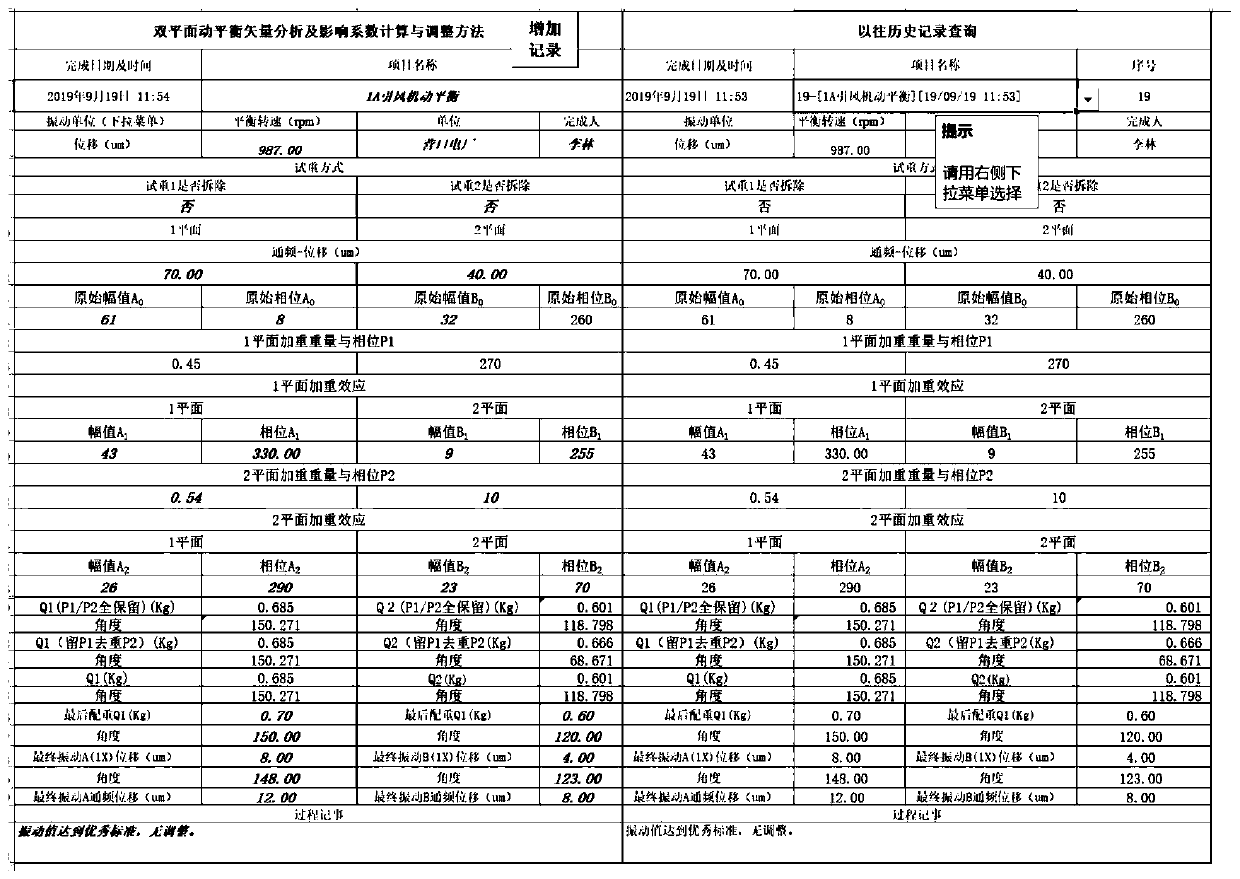

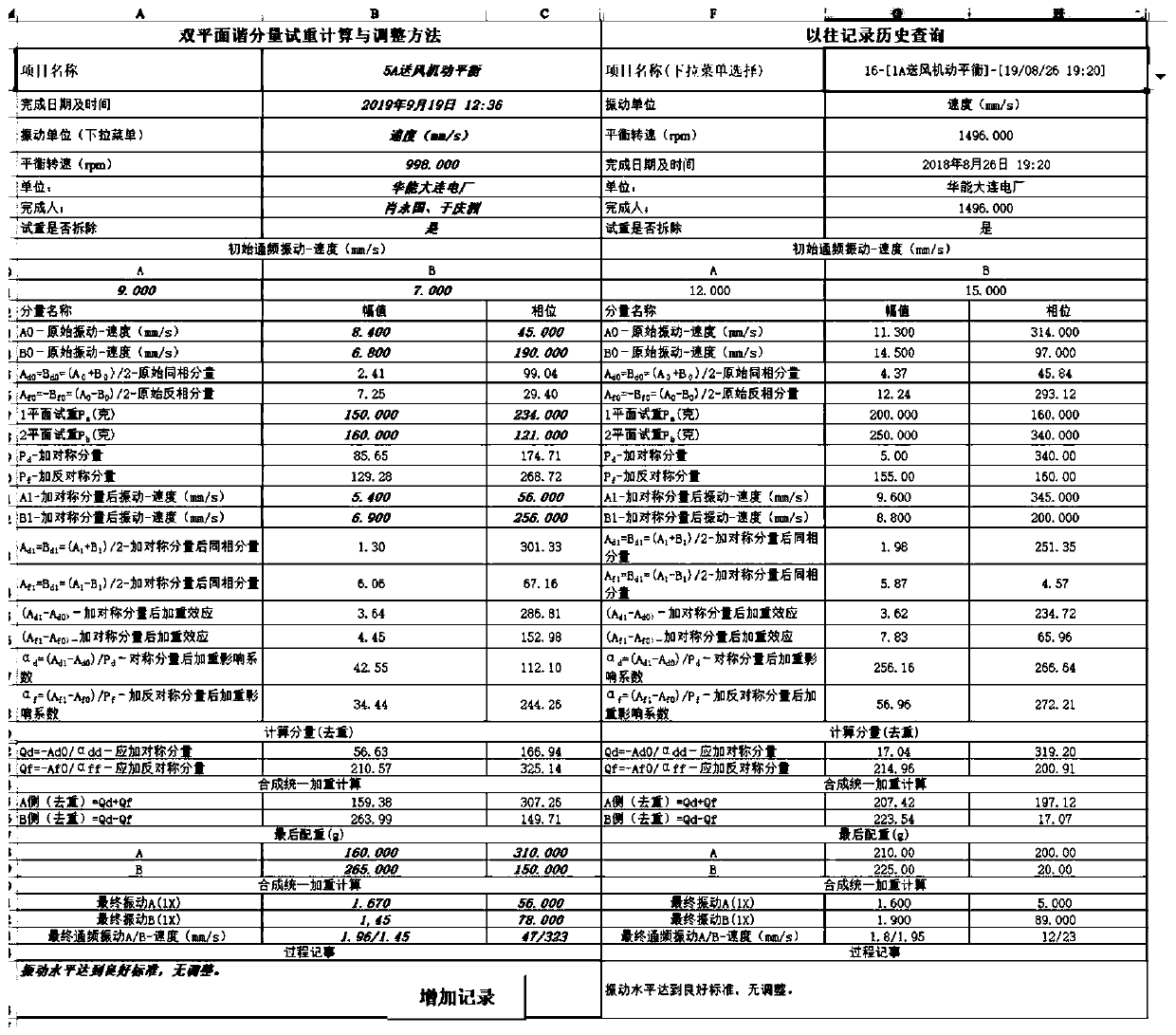

[0130] This embodiment provides a set of on-site dynamic balance calculation and adjustment methods for rotating machinery based on office software. The following on-site dynamic balance methods are application examples:

[0131] The vibration of a centrifugal fan seriously exceeds the standard, and the general frequency value of the horizontal vibration of the fan is measured A 通 = 210um, the double frequency amplitude and phase of the original vibration before the test is A 0 =204∠256°, the working speed is 2960 rpm.

[0132] 1. The existing single-plane dynamic balance vector analysis and influence coefficient calculation and adjustment methods are as follows:

[0133] Note: here α, A 0 、A 1 ,P t , ΔA are both vectors

[0134] P t : Trial weight (14g∠0°)

[0135] A 1 : Vibration after trial addition (186∠210°)

[0136] ΔA: effect vector, that is, the amount of vibration change before and after trial application

[0137] ΔA=A 1 -A 0 =186∠210°-204∠256°=153.28∠137°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com